Gravity

Sanitary Sewer

Design

and Construction

Second Edition

Prepared by a Joint Task Force of the

Environmental and Water Resources Institute and the

Pipeline Division Committee on Pipeline Planning of the

American Society of Civil Engineers

and the

Collection Systems Subcommittee of the

Technical Practice Committee of the

Water Environment Federation

Edited by Paul Bizier

ASCE Manuals and Reports on Engineering Practice No. 60

WEF Manual of Practice No. FD-5

Library of Congress Cataloging-in-Publication Data

Gravity sanitary sewer design and construction : ASCE manuals and reports on engineering

practice no. 60 wef manual of practice no. fd-5/ Prepared by the Joint Task Force on Sanitary

Sewers of the American Society of Civil Engineers and the Water Environment Federation

p. cm — (Wef manual ; no. 60)

Includes bibliographical references and index.

ISBN 13: 978-0-7844-0900-8

ISBN 10: 0-7844-0900-5

1. Sewerage—Design and construction. I. Bizier, Paul. II. American Society of Civil

Engineers. III. Water Environment Federation.

TD678.G715 2007

628′.2—dc22

2007015717

Published by American Society of Civil Engineers

1801 Alexander Bell Drive

Reston, Virginia 20191

www.pubs.asce.org

Any statements expressed in these materials are those of the individual authors and do

not necessarily represent the views of ASCE or WEF, which take no responsibility for any

statement made herein. No reference made in this publication to any specific method, prod-

uct, process, or service constitutes or implies an endorsement, recommendation, or warranty

thereof by ASCE or WEF. The materials are for general information only and do not repre-

sent a standard of ASCE or WEF, nor are they intended as a reference in purchase specifica-

tions, contracts, regulations, statutes, or any other legal document.

ASCE and WEF make no representation or warranty of any kind, whether express or

implied, concerning the accuracy, completeness, suitability, or utility of any information,

apparatus, product, or process discussed in this publication, and assume no liability therefor.

This information should not be used without first securing competent advice with respect to

its suitability for any general or specific application. Anyone utilizing this information

assumes all liability arising from such use, including but not limited to infringement of any

patent or patents.

ASCE and American Society of Civil Engineers—Registered in U.S. Patent and Trademark

Office.

Water Environment Research, WEF, and WEFTEC are registered trademarks of the Water

Environment Federation.

Photocopies and reprints. You can obtain instant permission to photocopy ASCE publica-

tions by using ASCE’s online permission service (www.pubs.asce.org/authors/Rightslink

WelcomePage.htm). Requests for 100 copies or more should be submitted to the Reprints

Department, Publications Division, ASCE (address above); email: [email protected]. A

reprint order form can be found at www.pubs.asce.org/authors/reprints.html.

Copyright © 2007 by the American Society of Civil Engineers and the Water Environ-

ment Federation. Permission to copy must be obtained from both ASCE and WEF.

All Rights Reserved.

ISBN 978-0-7844-0900-8

ISBN 978-1-57278-240-2

Manufactured in the United States of America.

American Society of Civil Engineers/

Environmental and Water Resources Institute

Founded in 1852, the American Society of Civil Engineers (ASCE) rep-

resents more than 140,000 members of the civil engineering profession

worldwide, and is America’s oldest national engineering society. Created

in 1999, the Environmental and Water Resources Institute (EWRI) is an

Institute of ASCE. EWRI services are designed to complement ASCE’s tra-

ditional civil engineering base and to attract new categories of members

(non-civil engineer allied professionals) who seek to enhance their profes-

sional and technical development.

For information on membership, publications, and conferences, contact

ASCE/EWRI

1801 Alexander Bell Drive

Reston, VA 20191-4400

(703) 295-6000

http://www.asce.org

Water Environment Federation

Formed in 1928, the Water Environment Federation (WEF) is a not-for-

profit technical and educational organization with 32,000 individual

members and 80 affiliated Member Associations representing an addi-

tional 50,000 water quality professionals throughout the world. WEF and

its member associations proudly work to achieve our mission of preserv-

ing and enhancing the global water environment.

For information on membership, publications, and conferences, contact

Water Environment Federation

601 Wythe Street

Alexandria, VA 22314-1994 USA

(703) 684-2400

http://www.wef.org

MANUALS AND REPORTS

ON ENGINEERING PRACTICE

(As developed by the ASCE Technical Procedures Committee, July 1930,

and revised March 1935, February 1962, and April 1982)

A manual or report in this series consists of an orderly presentation of

facts on a particular subject, supplemented by an analysis of limitations

and applications of these facts. It contains information useful to the aver-

age engineer in his or her everyday work, rather than findings that may

be useful only occasionally or rarely. It is not in any sense a “standard,”

however; nor is it so elementary or so conclusive as to provide a “rule of

thumb” for nonengineers.

Furthermore, material in this series, in distinction from a paper (which

expresses only one person’s observations or opinions), is the work of a

committee or group selected to assemble and express information on a

specific topic. As often as practicable, the committee is under the direction

of one or more of the Technical Divisions and Councils, and the product

evolved has been subjected to review by the Executive Committee of

the Division or Council. As a step in the process of this review, proposed

manuscripts are often brought before the members of the Technical Divi-

sions and Councils for comment, which may serve as the basis for

improvement. When published, each work shows the names of the com-

mittees by which it was compiled and indicates clearly the several pro-

cesses through which it has passed in review, in order that its merit may

be definitely understood.

In February 1962 (and revised in April 1982) the Board of Direction

voted to establish a series entitled “Manuals and Reports on Engineering

Practice,” to include the Manuals published and authorized to date, future

Manuals of Professional Practice, and Reports on Engineering Practice. All

such Manual or Report material of the Society would have been refereed in

a manner approved by the Board Committee on Publications and would

be bound, with applicable discussion, in books similar to past Manuals.

Numbering would be consecutive and would be a continuation of present

Manual numbers. In some cases of reports of joint committees, bypassing

of Journal publications may be authorized.

13 Filtering Materials for Sewage Treat-

ment Plants

14 Accommodation of Utility Plant Within

the Rights-of-Way of Urban Streets

and Highways

35 A List of Translations of Foreign Litera-

ture on Hydraulics

40 Ground Water Management

41 Plastic Design in Steel: A Guide and

Commentary

45 How to Work Effectively with Consult-

ing Engineers

46 Pipeline Route Selection for Rural and

Cross-Country Pipelines

47 Selected Abstracts on Structural Appli-

cations of Plastics

49 Urban Planning Guide

50 Planning and Design Guidelines for

Small Craft Harbors

51 Survey of Current Structural Research

52 Guide for the Design of Steel Transmis-

sion Towers

53 Criteria for Maintenance of Multilane

Highways

54 Sedimentation Engineering

55 Guide to Employment Conditions for

Civil Engineers

57 Management, Operation and Mainte-

nance of Irrigation and Drainage

Systems

59 Computer Pricing Practices

60 Gravity Sanitary Sewer Design and Con-

struction (Second Edition)

62 Existing Sewer Evaluation and

Rehabilitation

63 Structural Plastics Design Manual

64 Manual on Engineering Surveying

65 Construction Cost Control

66 Structural Plastics Selection Manual

67 Wind Tunnel Studies of Buildings and

Structures

68 Aeration: A Wastewater Treatment

Process

69 Sulfide in Wastewater Collection and

Treatment Systems

70 Evapotranspiration and Irrigation Water

Requirements

71 Agricultural Salinity Assessment and

Management

72 Design of Steel Transmission Pole

Structures

73 Quality in the Constructed Project:

A Guide for Owners, Designers, and

Constructors

74 Guidelines for Electrical Transmission

Line Structural Loading

76 Design of Municipal Wastewater Treat-

ment Plants

77 Design and Construction of Urban

Stormwater Management Systems

78 Structural Fire Protection

179 Steel Penstocks

180 Ship Channel Design

181 Guidelines for Cloud Seeding to Aug-

ment Precipitation

182 Odor Control in Wastewater Treat-

ment Plants

183 Environmental Site Investigation

184 Mechanical Connections in Wood

Structures

185 Quality of Ground Water

186 Operation and Maintenance of Ground

Water Facilities

187 Urban Runoff Quality Manual

188 Management of Water Treatment Plant

Residuals

189 Pipeline Crossings

190 Guide to Structural Optimization

191 Design of Guyed Electrical Transmis-

sion Structures

192 Manhole Inspection and Rehabilitation

193 Crane Safety on Construction Sites

194 Inland Navigation: Locks, Dams, and

Channels

195 Urban Subsurface Drainage

196 Guide to Improved Earthquake Perfor-

mance of Electric Power Systems

197 Hydraulic Modeling: Concepts and

Practice

198 Conveyance of Residuals from Water

and Wastewater Treatment

199 Environmental Site Characterization

and Remediation Design Guidance

100 Groundwater Contamination by

Organic Pollutants: Analysis and

Remediation

101 Underwater Investigations

102 Design Guide for FRP Composite Con-

nections

103 Guide to Hiring and Retaining Great

Civil Engineers

104 Recommended Practice for Fiber-

Reinforced Polymer Products for

Overhead Utility Line Structures

105 Animal Waste Containment in

Lagoons

106 Horizontal Auger Boring Projects

107 Ship Channel Design

108 Pipeline Design for Installation by

Horizontal Directional Drilling

109 Biological Nutrient Removal (BNR)

Operation in Wastewater Treatment

Plants

110 Sedimentaion Engineering: Processes,

Measurments, Modeling, and

Practice

111 Reliability-Based Design of Utility Pole

Structures

112 Pipe Bursting Projects

113 Substation Structure Design Guide

MANUALS AND REPORTS

ON ENGINEERING PRACTICE

No. Title No. Title

Manuals of Practice of the

Water Environment Federation

The WEF Technical Practice Committee (formerly the Committee on

Sewage and Industrial Wastes Practice of the Federation of Sewage and

Industrial Wastes Associations) was created by the Federation Board of

Control on October 11, 1941. The primary function of the Committee is

to originate and produce, through appropriate subcommittees, special

publications dealing with technical aspects of the broad interests of the

Federation. These publications are intended to provide background infor-

mation through a review of technical practices and detailed procedures

that research and experience have shown to be functional and practical.

Water Environment Federation Technical Practice

Committee Control Group

B. G. Jones, Chair

J. A. Brown, Vice Chair

S. Biesterfeld-Innerebner

R. Fernandez

S. S. Jeyanayagam

Z. Li

M. D. Nelson

S. Rangarajan

E. P. Rothstein

A. T. Sandy

A. K. Umble

T. O. Williams

J. Witherspoon

vii

ABSTRACT

This Manual provides both theoretical and practical guidelines for the

design and construction of gravity sanitary sewers.

The initial chapter introduces the organization and administrative

phases of the sanitary sewer project. Subsequent chapters are presented in

a sequence detailing the parameters necessary to establish the design cri-

teria, complete the design, and award a construction contract. The Man-

ual concludes with a discussion of the commonly used trenchless and

conventional methods of sanitary sewer construction.

This Manual is intended to be of practical use to the designer of a grav-

ity sanitary sewer system and is based upon the experience of engineers

in the field of sanitary sewer structural and hydraulic design. Charts,

illustrations, and example problem solutions are used liberally through-

out to reinforce the text.

Joint Task Force on Sanitary Sewers

Richard Thomasson, Chairman, Chapter 6

Dennis Doherty, Vice-Chair, Chapter 12*

Paul Bizier, EWRI Liason, Chapters 6, 9

Marsha Slaughter, Secretary

Matt Cassel, Chapter 8*

Rao Chitikela

John Christopher, Chapter 8*

Jacques Delleur, Chapter 3*

John Duffy

Angie Essner, Chapter 7*

Mike Glasgow

James Joyce, Chapter 4*

Karen Karvazy, Chapter 10*

Lisa Lassi, Chapter 10*

LaVere Merritt, Chapter 3*

Terry Moy

Mike Murphy

Mohammad Najafi, Chapter 12*

Aaron Nelson, Chapters 2, 7*

Paul Passaro, Chapter 1*

Morris Sade

Sam Samandi, Chapter 9

Howard Selznick, Chapter 3*

Mark M. Smith, Chapter 4

Carl Sutter, Chapter 10*

John Trypus, Chapter 1*

Michael VanDine

In addition to the Task Force, Blue Ribbon Panel reviewers included:

Wayne Dillard, Burns & McDonnell

Terry Walsh, Greeley and Hanson

Heidi Dexheimer, G. C. Wallace, Inc.

Staff assistance was provided by Lorna Ernst for the Water Environment Federa-

tion and Suzanne Coladonato for the American Society of Civil Engineers.

*principal contributing author.

ix

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 ORGANIZATION AND ADMINISTRATION

OF SANITARY SEWER PROJECTS . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Definition of Terms and Classification of Sanitary Sewers . . . . . 2

1.3 Phases of Project Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Interrelations of Project Development Phases . . . . . . . . . . . . . . . 6

1.5 Parties Involved in Design and Construction of Sanitary

Sewer Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Role of Parties in Each Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.7 Control of Sanitary Sewer System Use . . . . . . . . . . . . . . . . . . . . . 10

1.8 Federal and State Planning and Funding Assistance . . . . . . . . . 12

1.9 Local Funding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.10 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.11 National Environmental Policy Act of 1969 . . . . . . . . . . . . . . . . . 18

1.12 Capacity, Management, Operations, and

Maintenance (CMOM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.13 Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2 SURVEYS AND INVESTIGATIONS . . . . . . . . . . . . . . . . . . . . . 25

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.2 Types of Information Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.3 Sources of Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.4 Surveys for Different Project Phases . . . . . . . . . . . . . . . . . . . . . . . 30

2.5 Investigations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

CONTENTS

3 QUANTITY OF WASTEWATER . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.2 Design Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.3 Population or Dwelling Unit Forecast . . . . . . . . . . . . . . . . . . . . . . 39

3.4 Land Use and/or Employee Forecasts . . . . . . . . . . . . . . . . . . . . . 41

3.5 Average Unit Flows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.6 Average Flows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.7 Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.8 Infiltration/Inflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.9 Peak and Minimum Flows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.10 Uncertainty in Forecasts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4 CORROSION PROCESSES AND CONTROLS IN

MUNICIPAL WASTEWATER COLLECTION SYSTEMS . . . . 63

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.2 Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.3 Nonbiological Corrosion Processes . . . . . . . . . . . . . . . . . . . . . . . . 66

4.4 Microbiologically Induced Corrosion Processes . . . . . . . . . . . . . 83

4.5 Corrosion Prediction Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.6 Sulfide Corrosion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

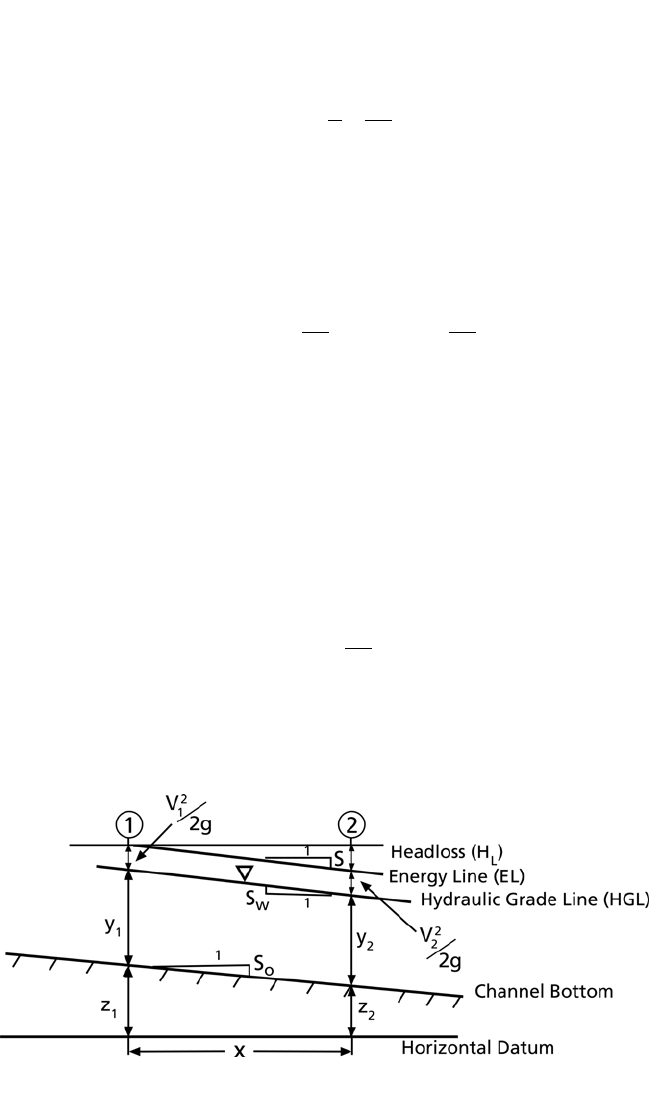

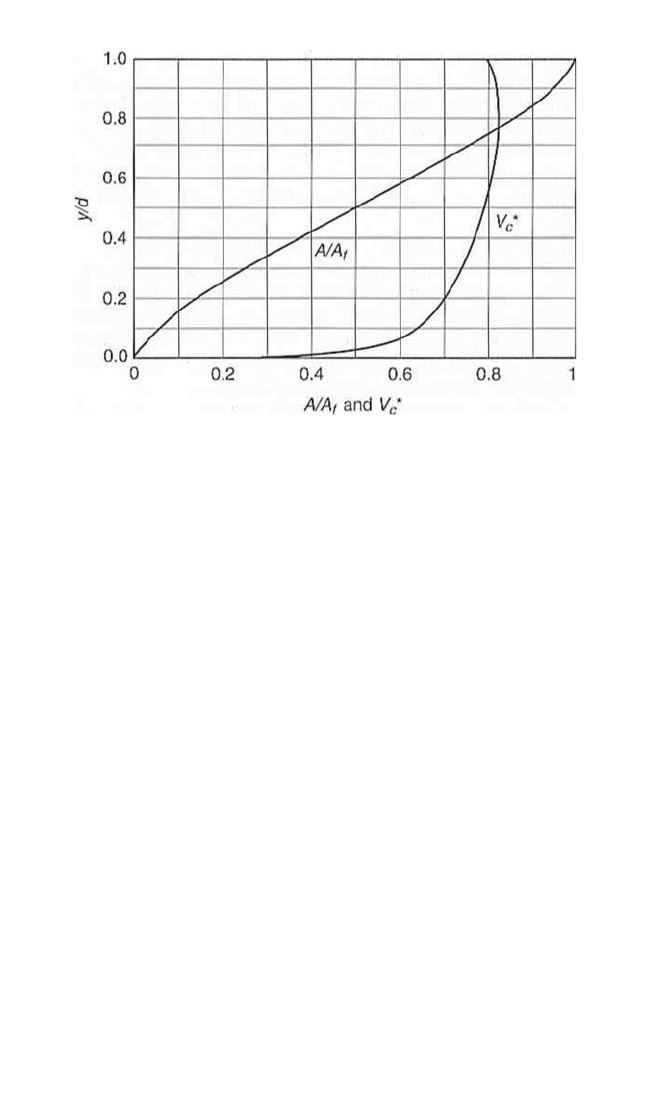

5 HYDRAULICS OF SEWERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5.2 Terminology and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

5.3 Hydraulic Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

5.4 Flow Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

5.5 Self-Cleansing in Sanitary Sewers . . . . . . . . . . . . . . . . . . . . . . . . . 134

5.6 Design Computations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

5.7 Hydraulic Continuity Through Manholes . . . . . . . . . . . . . . . . . . 152

5.8 Head Loss in Manholes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

5.9 Water Surface Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

5.10 Service Lateral Slopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

5.11 Partial Listing of Current Sewer Analysis/Design Software . . . . 156

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

6 DESIGN OF SANITARY SEWER SYSTEMS . . . . . . . . . . . . . . 165

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6.2 Energy Concepts of Sewer Systems . . . . . . . . . . . . . . . . . . . . . . . . 166

x CONTENTS

6.3 Combined Versus Separate Sewers . . . . . . . . . . . . . . . . . . . . . . . . 166

6.4 Layout of System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

6.5 Curved Sanitary Sewers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

6.6 Type of Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

6.7 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

6.8 Depth of Sanitary Sewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

6.9 Flow Velocities and Design Depths of Flow . . . . . . . . . . . . . . . . . 178

6.10 Infiltration/Inflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

6.11 Infiltration/Exfiltration and Low-Pressure Air Testing . . . . . . . 180

6.12 Design for Various Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

6.13 Relief Sewers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

6.14 Organization of Computations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

7 APPURTENANCES AND SPECIAL STRUCTURES . . . . . . . . 191

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

7.2 Manholes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

7.3 Bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

7.4 Junctions and Diversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

7.6 Terminal Cleanouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

7.7 Service Laterals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

7.8 Check Valves and Relief Overflows . . . . . . . . . . . . . . . . . . . . . . . . 204

7.9 Siphons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

7.10 Flap Gates or Duckbill Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

7.11 Sewers Above Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

7.12 Underwater Sewers and Outfalls . . . . . . . . . . . . . . . . . . . . . . . . . . 211

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

8 MATERIALS FOR SEWER CONSTRUCTION . . . . . . . . . . . . . 223

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

8.2 Sewer Pipe Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

8.3 Pipe Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

8.4 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

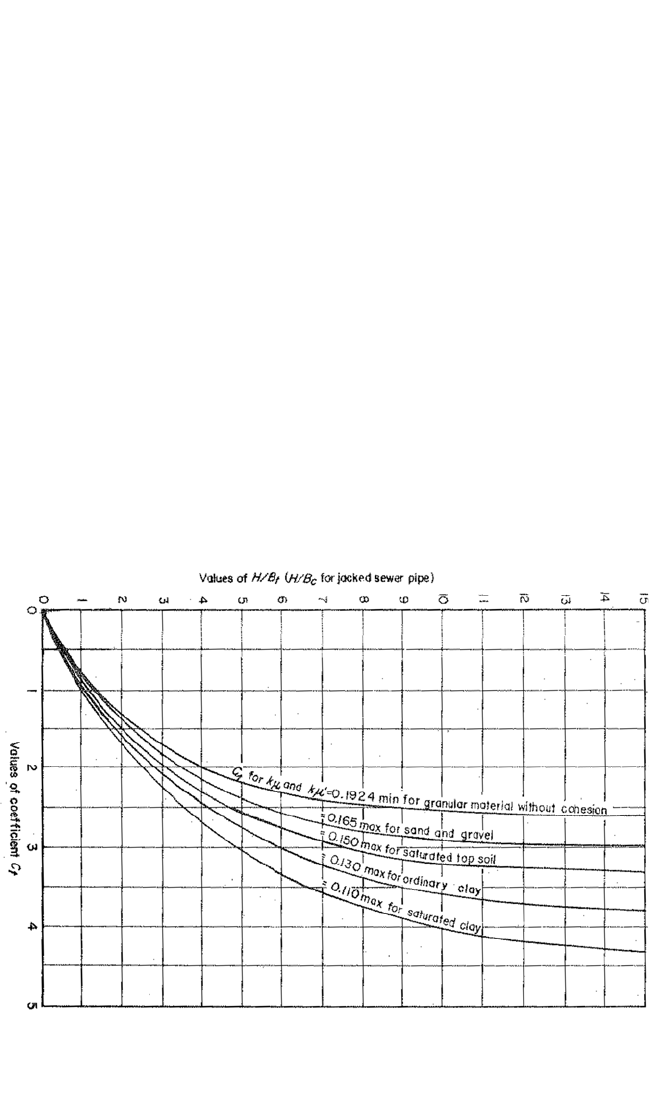

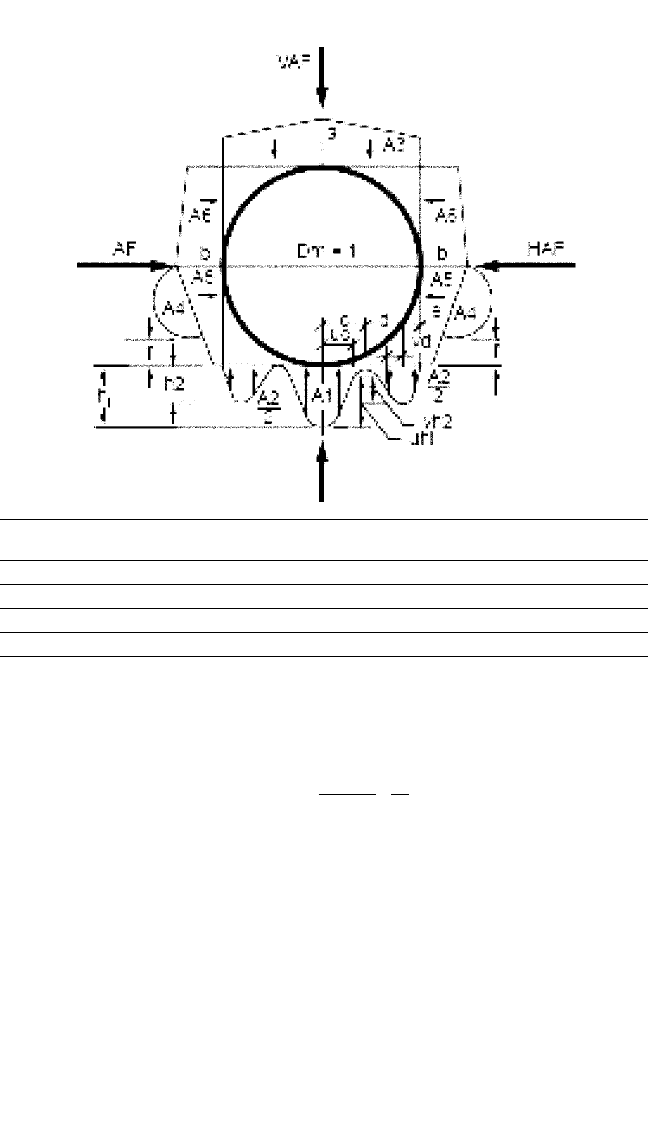

9 STRUCTURAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . 239

9.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

9.2 Loads on Sewers Caused by Gravity Earth Forces . . . . . . . . . . . 240

9.3 Live Loads and Minimum Cover . . . . . . . . . . . . . . . . . . . . . . . . . . 265

9.4 Direct Design and Indirect Design . . . . . . . . . . . . . . . . . . . . . . . . . 276

9.5 Rigid Pipe Structural Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

CONTENTS xi

9.6 Flexible Pipe Structural Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

9.7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

10 CONSTRUCTION CONTRACT DOCUMENTS . . . . . . . . . . . 341

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

10.2 Contract Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

10.3 Project Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366

11 CONSTRUCTION METHODS . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

11.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

11.2 Project Costs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

11.3 Construction Surveys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 370

11.4 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

11.5 Open-trench Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

11.6 Special Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

11.7 Sewer Appurtenances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

11.8 Project Acceptance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

12 TRENCHLESS DESIGN AND CONSTRUCTION . . . . . . . . . 395

12.1 Introduction and Comparison of Trenchless

Technology Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

12.2 Costs of Utility Construction Using Trenchless

Installation Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

12.3 Design Considerations for Trenchless Pipeline

Construction Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

12.4 Pipe Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

12.5 Horizontal Auger Boring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

12.6 Pipe Ramming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

12.7 Pipe Jacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

12.8 Horizontal Directional Drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

12.9 Microtunneling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 409

12.10 Pilot-tube Microtunneling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

12.11 Pipe Bursting Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 411

Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

xii GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

xiii

FOREWORD

In 1960, a joint committee of the Water Pollution Control Federation

(WPCF) and the American Society of Civil Engineers (ASCE) published

the Manual of Practice on the Design and Construction of Sanitary and

Storm Sewers. In 1964, a second joint committee was formed to revise and

expand the Manual; in 1969, the revised edition was published. In subse-

quent reprintings, the 1969 edition of the Manual was continuously

revised to provide information on improved and more current practices.

In 1978, the WPCF authorized preparation of this Manual of Practice

devoted to gravity sanitary sewers. In 1979, ASCE entered into an agree-

ment with WPCF to continue their joint publication relationship. Since that

time, the Water Environment Federation (WEF, formerly the WPCF) and

the Environmental and Water Resources Institute (EWRI) of ASCE have

continued to work together on joint publications. As a result, a joint com-

mittee of the Water Pollution Control Committee of EWRI, the Pipeline

Division of ASCE, and the Collection Systems Subcommittee of WEF’s

Technical Practice Committee was formed in 2004 to update this Manual.

This Manual should be considered by the practicing engineer as an aid

and a checklist of items to be considered in a gravity sanitary sewer proj-

ect, as represented by acceptable current procedures. It is not intended to

be a substitute for engineering experience and judgment, or a treatise

replacing standard texts and reference material.

In common with other manuals prepared on special phases of engi-

neering, this Manual recognizes that this field of engineering is con-

stantly progressing with new ideas, materials, and methods coming into

use. Other alternatives available to the designer of sanitary sewers

include vacuum, pressure, vacuum-pressure, and small-diameter grav-

ity sewers. It is hoped that users will present any suggestions for improve-

ment to the Technical Practice Committee of WEF, to EWRI, and to the

Pipeline Division of ASCE for possible inclusion in future revisions to

keep this Manual current.

The members of the Committee thank the reviewers of this Manual for

their assistance in submitting their suggestions for improvement.

This page intentionally left blank

1.1. INTRODUCTION

Wastewater treatment and collection systems are a major expenditure

of public funds, but the wastewater system’s function is rarely acknowl-

edged and sewers are seldom seen by the public. Sanitary systems are

essential to protecting the public health and welfare in all areas of concen-

trated population and development. Every community produces waste-

water of domestic, commercial, and industrial origin. Sanitary sewers

perform the vitally needed functions of collecting these wastewaters and

conveying them to points of treatment and disposal.

The various stages of design and construction of sanitary sewer pro-

jects require an understanding of the objectives of each stage of the project

and of the responsibilities and interests of the parties involved.

Separate sanitary and storm sewers are highly desirable and are used,

with few exceptions, in new systems. The major advantages of separate

systems, including wastewater treatment plants, are the protection of

watercourses from pollution and the exclusion of stormwater from the

treatment system with a consequent saving in treatment plant construction

and operating cost. Combined sewers are frequently encountered in older

communities where it may be extremely difficult or costly to provide sepa-

rate systems. Separation is desired, where economically feasible, to reduce

the magnitude of facilities and energy demand of treatment works.

Municipal sewer systems have been a major topic of regulatory interest

since the late 1990s with the introduction of the Sanitary Sewer Overflow

Rule and changes in financial accounting and reporting standards for

state and local governments. Under the provisions of the Clean Water Act

(CWA) of 1972 as amended, owners and operators of municipal waste-

water sewer systems are prohibited to release non-permitted discharges

CHAPTER 1

ORGANIZATION AND ADMINISTRATION

OF SANITARY SEWER PROJECTS

1

into receiving waters of the United States. A National Pollutant Discharge

Elimination System (NPDES) permit must be issued to include the allow-

able discharge points for treated wastewater, combined sewer overflows,

and emergency relief overflows. However, Section 301(a) of the CWA

does not include sufficient information to indicate if and when a sanitary

sewer overflow (SSO) might be permitted. The Environmental Protection

Agency (EPA) believes that the number of SSOs can be significantly

reduced through improved sewer system capacity, management, opera-

tion, and maintenance (CMOM). To address this important issue, the EPA

issued a Notice of Proposed Rulemaking on January 4, 2001 to introduce

the SSO Rule and CMOM Regulations. The proposed SSO Rule and

CMOM regulations would expand the NPDES permit requirements for

municipal sanitary sewer collection systems and clarify sanitary sewer

overflow prohibitions.

The proposed SSO Rule is intended to clarify the prohibition on SSO

discharges into the waters of the United States outlined in Section 301(a)

of the Clean Water Act. In June, 1999, the Government Accounting Stan-

dards Board (GASB) issued Statement 34 (GASB 34) which changed the

financial accounting and reporting standards for state and local govern-

ments. Of important relevance, the new standard requires that municipal-

ities record and report depreciation on their wastewater infrastructure

assets. Municipalities are required to use an asset management system

that maintains a current inventory of their wastewater and associated

sewer system infrastructure.

1.2. DEFINITION OF TERMS AND CLASSIFICATION

OF SANITARY SEWERS

The following terms as used in this Manual are defined in the Glossary—

Water and Wastewater Control Engineering (APHA 1981) as follows:

Building Drain: In plumbing, that part of the lowest horizontal piping

within a building that conducts water, wastewater, or stormwater to a

building sewer.

Building Sewer: In plumbing, the extension from the building drain to the

public sewer or other place of disposal. Also called House Connection.

Combined Sewer: A sewer intended to receive both wastewater and

storm or surface water.

Force Main: Liquid conveyance under pressure to raise liquid to the

desired elevation.

Intercepting Sewer: A sewer that receives dry-weather flow from a num-

ber of transverse sewers or outlets and, frequently, additional predeter-

2 GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

mined quantities of stormwater (if from a combined system), and con-

ducts such waters to a point for treatment or disposal.

Lateral Sewer: A sewer that discharges into a branch or other sewer and

has no other common sewer tributary to it.

Main Sewer: (1) In larger systems, the principal sewer to which branch

sewers and submains are tributary; also called Trunk Sewer. In small

systems, a sewer to which one or more branch sewers are tributary.

(2) In plumbing, the public sewer to which the house or building sewer

is connected.

Relief Sewer: (1) A sewer built to carry flows in excess of the capacity of

an existing sewer. (2) A sewer intended to carry a portion of the flow

from a district that has insufficient sewer capacity to another sewer

with available capacity to prevent overloading and possible overflows.

Relief sewers may also be used to eliminate overflows to combined

sewer outfalls when they are constructed as part of a treatment plant

and expansion.

Sanitary Sewer: A sewer that carries liquid and waterborne wastes from

residences, commercial buildings, industrial plants, and institutions,

together with minor quantities of ground, storm, and surface waters

that are not admitted intentionally. See also Wastewater.

Separate Sewer: A sewer intended to receive only wastewater, storm-

water, or surface water. See also Combined Sewer, Sanitary Sewer,

and Storm Sewer.

Separate Sewer System: A sewer system carrying sanitary wastewater

and other waterborne wastes from residences, commercial buildings,

industrial plants, and institutions, together with minor quantities of

ground, storm, and surface waters that are not intentionally admitted.

See also Wastewater, Combined Sewer.

Storm Sewer: A sewer that carries stormwater and surface water, street

wash and other wash waters, or drainage, but excludes domestic

wastewater and industrial wastes. Also called Storm Drain.

Outfall: (1) The point, location, or structure where wastewater or drainage

discharges from a sewer, drain, or other conduit. (2) The conduit lead-

ing to the ultimate disposal area.

Outfall Sewer: A sewer that receives wastewater from a collecting system

or from a treatment plant and carries it to a point of final discharge.

Trunk Sewer: A sewer that receives many tributary branches and serves a

large territory.

Waste Water: In a legal sense, water that is not needed or that has been

used and is permitted to escape, or which unavoidably escapes from

ditches, canals or other conduits, or reservoirs of the lawful owners of

such structures. See also Wastewater.

Wastewater: The spent or used water of a community or industry, which

contains dissolved and suspended matter.

ORGANIZATION OF SANITARY SEWER PROJECTS 3

1.3. PHASES OF PROJECT DEVELOPMENT

Conception and development of typical sanitary sewer projects com-

prise the following phases:

1.3.1. Preliminary or Investigative Phase

The objective of this phase is to establish the broad technical and eco-

nomic bases for environmental assessments, policy decisions, and final

designs. The importance of this phase cannot be overemphasized. Inade-

quate preliminary work will be detrimental to all succeeding phases and

may endanger the successful completion of the project or cause the owner

to undertake planning which may not produce the most economical or

efficient result. This phase usually culminates in an engineering report,

which includes items such as:

• Statement of the problem and review of existing conditions.

• Capacities and conditions required to provide service for design

period.

• Method of achieving the required service—if more than one method

is available, an evaluation of each alternative method.

• General layouts of the proposed system with indication of stages of

development to meet the ultimate condition when the project war-

rants stage development.

• Establishment of applicable engineering criteria and preliminary

sizing and design that will permit preparation of construction and

operating cost estimates of sufficient accuracy to provide a firm

basis for feasibility determination, financial planning, and consider-

ation of alternative methods of solution.

• Various available methods of financing and their applicability to the

project.

• An assessment of the anticipated environmental impacts of con-

struction and review of the long-term effects on the environment.

The environmental assessment, when required, must be sufficiently

thorough and objective to enumerate the environmental conse-

quences of the project. Measures to mitigate any negative impacts

should be set forth. Projects that have community-wide conse-

quences and that are supported by federal funds may be subjected

to detailed evaluation through Federal Environmental Impact State-

ment procedures.

• Operation and maintenance factors related to confined space entry

requirements, as regulated by the Occupational Safety and Health

Administration (OSHA), should be considered during the prelimi-

nary engineering phase. Design consideration should be given by

4 GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

the engineer to facilitate safe ingress and egress into manholes and

sewers, platforms, safety ladders, etc. Manholes should be accessible

for scheduled maintenance. The accessibility of back line systems is

critical and easements are recommended for maintenance purposes.

• The selection of conveyance materials is critical. The corrosion

induced by microbial action, low pH levels, and hydrogen sulfide

gas must be considered when materials and linings are evaluated.

Some materials will require protection from stray currents and the

debilitating effect they will have on conveyance systems. Polyethyl-

ene wrapping, polyvinyl chloride (PVC) lining, and cathodic protec-

tion are standard responses to these issues.

• The construction of a sanitary sewer system will inevitably require

that streets and arterial highways be excavated or trenchless meth-

ods be utilized (see Chapter 12). Further, wetlands may be affected

and the system may require approvals from many jurisdictions,

municipalities, counties, and state and federal agencies. This coor-

dination and permitting in itself may weigh heavily on the con-

struction methods utilized—the cost of traffic interruption, loss of

revenue in commercial districts, and environmentally sensitive land

disturbance are critical elements in the planning process and may

require that the engineer and owner evaluate trenchless construc-

tion methods for new construction during this phase. The trenchless

methods may include, among others, microtunneling, horizontal

directional drilling, and pipe bursting.

• Analysis of risk associated with infrastructure failure and well-

reasoned discussions on system component locations and materials

selected.

It must be recognized that the preliminary engineering report is not a

detailed working design or plan from which a sanitary sewer project can

be constructed. Indeed, such detail is not necessary to meet the objectives

of the preliminary or investigative phase or the environmental assess-

ment. Nonetheless, proper preliminary engineering is the fundamental

initial step of final planning. (For additional information concerning the

Survey and Investigation phases of sanitary sewer project development,

see Chapter 2.)

1.3.2. Design Phase

The design phase of a sanitary sewer project comprises the preparation

of construction plans and specifications. These documents form the basis

for bidding and performance of the work; they must be clear and concise.

Design therefore consists of the elaboration of the preliminary plan to

include all details necessary to construct the project.

ORGANIZATION OF SANITARY SEWER PROJECTS 5

1.3.3. Construction Phase

This phase involves the actual building of the project according to the

plans and specifications previously prepared.

1.3.4. Operation

Although this Manual is devoted to matters of design and construc-

tion, the efficient operation of a sanitary sewer system is an important ele-

ment to consider during the development of such projects.

1.4. INTERRELATIONS OF PROJECT DEVELOPMENT PHASES

Since all phases of sanitary sewer projects are interrelated, the follow-

ing points are applicable:

1. The capacity, arrangement, and details of a sanitary sewer system will

not be satisfactory unless the preliminary or investigative phase is cur-

rent and properly completed.

2. Adequate preliminary engineering and estimating are essential to

sound financial planning, without which subsequent phases of the

project may be placed in jeopardy.

3. Environmental assessment documentation is intended to provide a sin-

gle source of comparison and evaluation of all development, construc-

tion, and operation phases of the project.

4. Inadequate design or improperly prepared plans and specifications

can lead to confusion in construction, higher costs, failure of the project

to meet intended functions, or actual structural or hydraulic failure of

component parts.

5. Proper execution of the construction phase is necessary to produce the

quality and features intended by adequate design. Moreover, the value

of the design can be lost by incompetent or careless handling of the

construction phase.

6. All sanitary sewer projects have certain features requiring operation

and maintenance. Unless they are anticipated and provided for, the

usefulness of the project will be impaired.

7. The cost estimates for these sometimes expensive capital projects require

updating based on elapsed time and modifications to the project. Often,

changes are made that may have a significant impact on the overall final

cost. The updating process will ensure that all parties are aware of the

financial impact of the project as the design process evolves from the ini-

tial preliminary design to the final biddable documents.

8. The impact of the combination of limited space and major renovation

to existing systems will add cost for, among others, bypass pumping

and inherent delays due to the need for sequential construction. Cost

6 GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

estimates must factor in these hidden charges to the project. The soft

costs of contract bonds and insurance may also be significant as the

project construction costs increase.

The disruption to infrastructure, streets, utilities, and sediment and

erosion control requires the coordination of the project with other impacted

utilities and regulators having jurisdiction within the public right of way

(ROW). This analysis and coordination may have a significant impact on

route selection.

1.5. PARTIES INVOLVED IN DESIGN AND CONSTRUCTION

OF SANITARY SEWER PROJECTS

Engineering projects, including sanitary sewers, are the result of the

combined efforts of several interested parties. The owner, engineer, and

contractor are the principal participants. Legal counsel, financial consult-

ant, various regulatory agencies, and other specialists also are involved to

varying degrees. Responsibilities of these individuals or organizations are

summarized as follows.

1.5.1. Owner

The owner’s needs initiate the project and he provides the necessary

funds. The owner is party to all contracts for services and construction

and may act directly or through any duly authorized agent. The owner

most often is the collective citizens of a governmental unit whose affairs

may be handled by various legislative and administrative bodies. The

owner may also be a private group.

When the owner is a governmental unit, its business may be conducted

by one of the following, depending on the organization of the unit and the

laws controlling its operations:

• City councils or similar bodies, carrying out sanitary sewer projects

as only one of many duties for the given unit.

• A special commission or board of a governmental unit dealing with

more limited areas of interest than are usually are handled by a city

council. Such boards or commissions may be concerned with sanitary

sewer projects alone or with a governmental unit’s general utility sys-

tem. The geographical limits of responsibility of such boards or com-

missions usually coincide with those of the parent governmental unit.

• A legislatively established district, agency, or authority with unique

geographical limits and whose affairs are administered by a sepa-

rate and distinct administrative board or commission. Such units

commonly are referred to as districts or authorities—for example,

ORGANIZATION OF SANITARY SEWER PROJECTS 7

the County Sanitation Districts of Los Angeles County, which

includes 74 separate cities and the unincorporated county. Often,

the responsibilities of such sewering districts are limited to main

trunk sanitary sewers, intercepting sanitary sewers, treatment facil-

ities, and outfalls, leaving lateral sewers as the responsibility of the

individual governmental units within the area served by the larger

district.

The fund-raising powers of the first two bodies are usually regulated

by the same laws, which apply to financing by the parent governmental

unit. Fund-raising powers for a specially constituted district may show

considerable variation due to the many differences in legislative provi-

sions for special district formation and financing.

Temporary private ownership of sanitary sewer projects is sometimes

encountered in new developments. The developer may construct the san-

itary sewer system and later transfer title to the appropriate governmental

unit in accordance with local regulations. In some instances, wastewater

systems and treatment works are under the permanent ownership of pri-

vate utility companies. The design and construction of these private sys-

tems require that the agency that will or may assume authority maintain a

presence during design and construction process.

1.5.2. Engineer

The engineer has the responsibility of supplying the owner with the

basic information needed to make project implementation policy deci-

sions, detailed plans and specifications necessary to bid and construct the

project, consultation, general and resident inspection during construction,

and services necessary for the owner to establish satisfactory operation

and maintenance procedures. The engineer’s responsibilities are all of a

professional character and must be discharged in accordance with ethical

standards by qualified engineering personnel.

Engineering for sanitary sewer projects may be performed either by

engineering departments which are a part of a governmental unit, or by

private engineering firms retained by the owner for specific projects. In

many instances, sanitary sewer projects are a joint effort by both types of

organizations.

1.5.3. Contractor

The contractor performs the actual construction work under the terms

of the contract documents prepared by the engineer. The construction

agreement is between the contractor and the owner. One or more contrac-

tors may perform the work on a single project.

8 GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

The functions of the contractor may be carried out by an owner’s

employees especially organized for construction purposes, but such prac-

tice for sanitary sewer projects of any magnitude is not common.

The complexity of many sanitary projects may require that the general

contractor have overall responsibility for associated subcontractors, and

an independent construction management firm to represent the owner.

1.5.4. Other Parties

Many other parties may be involved at various stages of a project.

Some of these are:

• Legal Counsel. All public works projects are subject to local and state

laws; competent legal advice is required to ensure compliance with

these laws and the avoidance of setbacks because of legal defects in

the project. Special legal counsel may also be required in connection

with financing the project, particularly where a bond issue is

involved.

• Financial Consultant. Advisory services with respect to project financ-

ing are often required and may be provided as a separate and spe-

cialized service. Such services are occasionally provided as part of a

general financing agreement with a financing agency.

• Regulatory Agencies. The most frequently encountered regulatory

body is the state Health Department, Department of Environmental

Quality, or, in some states, a specially designated water pollution

control agency which usually adopts minimum standards pertaining

to features of design, plans, and specifications for sanitary sewer

projects. Other regulatory bodies having jurisdiction may include

agencies such as municipality or sanitary sewer districts; local,

regional, or state planning commissions; federal agencies concerned

with water pollution control; and federal or state agencies having

functional control of navigable waters.

• Pipe Manufacturers. These manufacturers produce the specified pipe

materials and often will embark on focused developmental research

to prove or improve a specific pipe product.

1.6. ROLE OF PARTIES IN EACH PHASE

The roles of the owner, engineer, and contractor with respect to each

other in the different phases of the project are distinct. Unauthorized

assumption of roles and duties of one of the parties may result in delays,

failures, and/or contractual controversies. The legal counsel of the owner

ORGANIZATION OF SANITARY SEWER PROJECTS 9

usually will be responsible for all legal issues pertaining to funding and

compliance with the local purchasing statutes.

1.6.1. Preliminary or Investigative Phase

The owner and the engineer are the principal parties involved in the

preliminary phase of sanitary sewer projects. It must be recognized that

all policy decisions relating to the project, arranging for financing, etc.,

rest solely in the hands of the owner.

1.6.2. Design Phase

The design phase, up to the time of soliciting and receiving construc-

tion bids, involves both the owner and the engineer. Designs prepared by

the engineer are normally subject to the approval of the owner. The engi-

neer may recognize preferences of the owner and be guided by these pref-

erences when they are consistent with good engineering practice. The

engineer must recognize and conform to the legal, procedural, and regu-

latory requirements governing each project.

1.6.3. Construction Phase

In his relationship with the contractor, the engineer must exercise

authority on behalf of the owner. The engineer determines whether the

work is substantially in accordance with the requirements of the contract

documents. He must avoid direct supervision of the contractor’s con-

struction operations. If he does control or direct the acts of the contractor,

he may become involved as a third party in any legal action brought

against the contractor.

1.6.4. Operation Phase

Full information on the intended functioning of all parts of a project

should be furnished to the owner by the engineer. The owner’s staff must

assume final responsibility for operation at the time the project or any

part of it is completed and accepted by him. In some cases, the engineer,

by special agreement with the owner, may provide advisory services in

connection with operation and maintenance procedures for a period of

time after initial operation.

1.7. CONTROL OF SANITARY SEWER SYSTEM USE

Of all public utilities, sanitary sewer systems are probably the most

abused through misuse. This situation results from a misconception that a

10 GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

sanitary sewer can be used to carry away any unwanted substance or

object that can be put into it. The absence of adequate regulations setting

forth proper uses and limitations of the system, and the lack of enforce-

ment of existing regulations by those responsible for operation of the

system, tend to foster such a misconception. Abuse of the sanitary sewer

system can result in extensive damage and can compound the problems

of wastewater treatment. Without proper maintenance and control, a sani-

tary sewer system may become a hazard to public safety and may

increase operating costs unnecessarily.

The following are common consequences of sanitary sewer system

misuse:

• Explosion and fire hazards resulting from discharge of explosive or

flammable substances into the sanitary sewer.

• Sanitary sewer clogging by accumulations of grease, bed load, and

miscellaneous debris.

• Physical damage to sanitary sewer systems resulting from discharge

of corrosive or abrasive wastes.

• Surface and groundwater overload resulting from improper connec-

tions to sanitary sewers.

• Watercourse pollution resulting from discharge of wastewater to

storm sewers.

• Interference with wastewater treatment resulting from extreme wet-

weather flows or from wastes not amenable to normal treatment

processes.

• The overloading effect of rainfall-induced inflow and infiltration must

be evaluated and action taken to reduce or eliminate these elements to

ensure the overall effective operation of a wastewater collection and

treatment system. The presence of high rates of infiltration and the

negative impact of same to the treatment process are not trivial. The

cost of treating this non-wastewater flow, in metered communities,

presents a tangible annual cost that can be used for the determination

of current dollars that can be expended to correct these problems.

• The proposed SSO Rule and CMOM regulations, if enacted, will

have a significant impact on the legal responsibility of the owner of

the large or small sanitary sewer collection system to ensure that

their systems function efficiently. In addition, the fixed asset report-

ing requirements of GASB 34 will also require that these critical

assets are valued and enhanced on a continuing basis. Financial

institutions will review the value of depreciated infrastructure to

assess the bond rating of a borrowing agency or utility.

In the organization of sanitary sewer projects, as well as in the manage-

ment of completed systems, provision must be made for the controlled

ORGANIZATION OF SANITARY SEWER PROJECTS 11

use of the sanitary sewers and enforcement of appropriate regulations. A

comprehensive report on sanitary sewer ordinances can be obtained from

the Water Pollution Control Federation (WPCF 1975). Their publications

may be helpful in determining the adequacy of existing regulations or

preparing new ones.

1.8. FEDERAL AND STATE PLANNING

AND FUNDING ASSISTANCE

1.8.1. Federal Assistance

Federal programs to provide financial assistance for the construction of

publicly owned wastewater treatment and transport systems began in the

middle 1950s and have grown to major significance. In many states, fed-

eral financial assistance programs for qualified wastewater systems are

supplemented by state grant and loan programs. The engineer is frequently

responsible for locating such sources of financial assistance and preparing

the necessary applications for the owner.

The Water Pollution Control Act of 1972, amended as the Clean Water

Act of 1977 and 1981, was the most significant source of federal assistance.

This law initially required state water pollution control agencies and cer-

tain sub-state agencies to conduct planning for water quality manage-

ment. Currently, funding for wastewater infrastructure is in the form of

low-interest loans issued by the states. These loans are repaid and create a

revolving account from which other projects can be funded. Availability

of financial assistance for sanitary sewers varies from time to time and

from state to state, since it is subject to the policies of the federal govern-

ment and of individual states.

The second most significant source of federal assistance is the Farmers

Home Administration (FmHA). Grants and loans for such systems are

available primarily to small, rural communities. Other federal grants and

loans are available from the Department of Housing and Urban Develop-

ment (HUD), the Economic Development Administration (EDA), and a

variety of regional agencies such as the Appalachian Regional Commis-

sion (ARC) and the Coastal Plains Regional Commission (CPRC). Contact

should be made with state and federal elected officials to ascertain the

availability and sources of funding for wastewater treatment projects.

Federal assistance programs have provided significant aid to local

wastewater agencies, but they are often limited by federal appropriations

and generally have substantial requirements and administrative proce-

dures which must be followed. A review of current funding allocations

and regulations is necessary to determine availability of federal funds at

any given time.

12 GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

1.8.2. State Assistance

A majority of the 50 states operate programs to assist local govern-

ments in the planning and financing of wastewater projects, including

sanitary sewers. Many states have area planning and development com-

missions which prepare or assist in the preparation of planning docu-

ments for sanitary sewers for communities within their jurisdiction. States

operate grant and loan programs ranging from the very modest up to

100% of the cost of wastewater projects when supplemented by various

federal assistance programs. Such programs are usually administered by

the state water pollution control agencies or health departments. The

current status of state and local programs must be reviewed as a part of

project design activities. In order to distribute scarce resources more effi-

ciently, some jurisdictions issue low-interest loans to fund many sewer

system projects and to provide a revolving funding source.

1.9. LOCAL FUNDING

Local funding methods include the following:

1.9.1. General Obligation Bonds

These bonds are backed by the full faith and credit of the issuer and

often are paid for by the levy of general property taxes. In addition to or

instead of taxes, revenues from service charges or other sources may be

used to meet bond payments. Advantages of these bonds over other

bonds include lower interest rates because of the substantial security pro-

vided and the ease with which they may be sold. However, in most states

the issuance of general obligation bonds by local government is subject to

constitutional and statutory limitations and to voter approval.

1.9.2. Special Assessment Bonds

Such bonds are payable from the receipts of special benefits assess-

ments against certain properties or recipients of benefit. Assessments that

are not paid become a lien on the property. Assessments may be based on

front footage, area of parcels of property, or other bases. In most cases, the

prior consent of landowners representing some statutory percentage of the

total property to be assessed is required to implement special assessments.

1.9.3. Revenue Bonds

These bonds are payable from charges made for services provided.

Such bonds have advantages when agencies lack other means of raising

ORGANIZATION OF SANITARY SEWER PROJECTS 13

capital; they can be used to finance projects which extend beyond normal

agency boundaries. The success of revenue bonds depends upon eco-

nomic justification for the project, reputation of the agency, methods of

billing and collection, rate structures, provisions for rate increases, finan-

cial management policy, reserve funds, and forecast of net revenues.

1.9.4. Pay-As-You-Go Financing

This method entails gathering sufficient funding prior to and during

construction. Funds may be gathered through a system of increased user

charges and/or connection fees. Advantages of this method are elimina-

tion of interest cost and voter authorization. The principal disadvantage

is significantly higher charges during the period when funds are being

collected.

1.9.5. Revenue Programs and Rate Setting

Various methods are in use to obtain the revenue needed to operate,

maintain, replace, extend, and enlarge wastewater systems. The principal

methods include the levy of ad valorem taxes, service charges, connection

charges, and combinations of these. Each agency’s revenue program and

rate settings reflect the needs of an individual community and its local

policy. No single revenue-generating program can be considered ideal for

every situation.

Alternatives should be examined in terms of equity among user

groups, promotion of water conservation, and implementation and

updating requirements. Because the aim is to achieve fairness to all users

and beneficiaries—domestic, commercial, and industrial—it becomes

necessary to consider the question of fairness as a whole and not simply

from the standpoint of any one class. The procedures for allocating user

costs are easier to understand in specific examples than in the general

terms considered here. Examples are contained in various publications

prepared by ASCE, WEF, and the American Water Works Association

(AWWA).

1.9.5.1. Ad Valorem Taxes

Taxes on real estate may be used as a primary revenue source for

wastewater service in the event the agency has not accepted a federal

grant and, therefore, is not subject to restrictions under the Clean Water

Act or by taxing limitations. Real estate values and real estate taxes often

reflect ability to pay, which may be a primary criterion in reducing hard-

ship for some citizens. On the other hand, the value of real estate may

have little relationship to the cost of service which is provided to indi-

vidual users. There is often a preference for payment of service as a tax

14 GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

rather than as a service bill because the tax may be deductible from fed-

eral and state income taxes, whereas a service charge is not.

The strongest objection to ad valorem taxation as a method of cost

recovery comes from those who believe that benefits are strictly propor-

tional to quantity of wastewater or a combination of quantity and waste

characteristics.

The simplicity of an ad valorem tax system is a marked advantage. It

requires no wastewater measurement or sampling program for charge

purposes. The required accounting and billing work is minimal. Clearly

this procedure will require minimal overhead cost, but the lack of indi-

vidual user accountability may not encourage conservation.

1.9.5.2. Service Charges

Service charges provide financial support of wastewater systems based

on some measure of actual physical use of the system. Measures of use

include volume of wastewater; volume of wastewater plus quantity of pol-

lutant matter; number or size of sewer connections; type of property, such

as residential, commercial, or manufacturing; number and type of plumb-

ing fixtures, water-using devices, or rooms; uniform rates per connection;

and percent of water charge. A recent development is that, in some jurisdic-

tions, services changes are being applied by governing bodies to account

for infrastructure improvements to mitigate environmental impacts.

1.9.5.3. Connection Charges

A one-time charge at the time a user connects to a wastewater system is

used to generate revenue. Charges vary from a nominal inspection fee to

a full, prorated share of the cost of the entire wastewater system. In some

cases connection fees reflect costs to provide new capacity in the waste-

water system. Connection fees are not generally used for operation and

maintenance, but are used for purposes such as payment of debt service

and financing wastewater system expansion.

1.9.5.4. Combination Taxes and Service Charges

Combination systems have often resulted from an original ad valorem

tax system when additional sources of revenue were required and funds

raised from user revenues were unpopular or were politically precluded

from use to fund operation and maintenance costs. The Clean Water Act

requires that grantees implement a system of service charges based on

usage to pay for operation and maintenance costs.

The combination system can result in payment for operation of a

wastewater treatment system by nonusers who do not benefit from

these facilities. One can argue, however, that a wastewater collection sys-

tem creates a safe environment for all residents and may be a charge on a

pro rata basis to all residents.

ORGANIZATION OF SANITARY SEWER PROJECTS 15

This option should be evaluated carefully prior to implementation.

Issues of current public policy in a region or geographic area relative to

financing of a service which benefits a segment of a jurisdiction by general

taxation is a slippery slope indeed.

1.10. SAFETY

A goal in sanitary sewer projects is to eliminate unsafe conditions and

unsafe acts. To be effective, desire and enthusiasm for safety must be

encouraged and supported at all levels of employment in the owner

organization. Among the numerous laws, rules, and regulations which

govern safety is the Occupational Safety and Health Act of 1970.

1.10.1. Investigations

• Investigations or surveys, such as an EPA Sanitary Sewer Evalua-

tion Survey (SSES), should be conducted with safety as a paramount

consideration in accordance with regulations for equipment, train-

ing, and size of sewer entry crew.

• The engineer must provide a work environment for his workers that

recognizes hazards likely to cause death or serious physical harm.

This can be accomplished with the utilization of proper safety equip-

ment and procedures.

1.10.2. Design

• Safety factors are to be considered by the engineer for reducing the

ultimate strength of a material to a working strength. The factor of

safety will vary, depending on the type of material and its use. (A

comprehensive discussion of design considerations is presented in

Chapter 9.)

• The engineer must be familiar with safety practices and regula-

tions such as OSHA standards and how their requirements may

affect the design of the sanitary projects. Several of these design

standards include safety landings in manholes and confined space

procedures.

• Sanitary sewers should be separated from gas and water mains and

other buried utilities. Many states have regulations that set mini-

mum horizontal and vertical separation requirements.

• Ventilation should provide for air to enter the sanitary sewer system

and provide for the escape of gases. Currently, the trend is to utilize

16 GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

solid or watertight manhole covers in streets and water courses.

With the decrease in ventilation through holes in manhole covers,

inconspicuous vents or forced draft may be needed to provide ade-

quate ventilation.

1.10.3. Construction

• The construction contract documents should require the contractor

to adhere to all laws and regulations which bear on the project con-

struction and to be responsible for safety at the construction site.

• The OSHA standards require the employer (contractor) to provide

employees with a safe and healthful place of employment. Sections

of the OSHA standards state that it shall be the responsibility of

the employer to initiate and maintain such programs as may be

necessary to provide safe conditions, and that frequent and regular

inspections be made by competent persons designated by the

employers.

• The engineer should specifically instruct his own field personnel to

follow safety precautions while visiting the construction site. Field

personnel should be issued hardhats and eye goggles or other appro-

priate protective equipment for use while visiting the site.

• The terms of the contract documents entered into for a construction

project play an important role in determining whether or not an

engineer has any duty in regard to the safety of the contractor’s

employees. Litigation by injured employees of contractors naming

the engineer as a party to a suit often occurs. Unless the engineer

has specifically accepted responsibility for construction site safety,

the contract documents must provide that the contractor is respon-

sible for construction site safety. The engineer must nevertheless

take appropriate action if a potential safety hazard is observed.

1.10.4. Operation and Maintenance

• A safety program is necessary for the operation and maintenance of

a sanitary sewer system. Safety is the responsibility of every individ-

ual, not only for personal protection but also for the protection of

fellow employees.

• Safety equipment such as traffic control devices, safety harnesses,

tools for manhole cover removal, gas detectors and blowers with

duct discharge for positive displacement of manhole atmosphere,

and rubberized cloth gloves must be available for protection where

needed.

ORGANIZATION OF SANITARY SEWER PROJECTS 17

1.11. NATIONAL ENVIRONMENTAL POLICY ACT OF 1969

The National Environmental Policy Act of 1969 (NEPA) established

that Congress is interested in restoring and maintaining environmental

quality. It directs all federal agencies to identify and develop methods

and procedures to ensure that environmental factors be given appropriate

consideration in decision making along with economic and technical con-

siderations. NEPA applies also to any project implemented by federal

funds. A number of states have adopted legislation that parallels NEPA

for state and local activities.

If the nature of the proposed project and its impact does not obviously

reflect the need for the preparation of an Environmental Impact Statement

(EIS), an initial Environmental Assessment (EA) reviews the anticipated

effects of the proposed action. A conclusion is drawn as to whether the

proposed action would significantly and adversely affect the environ-

ment and therefore require the preparation of an EIS. If there is no signif-

icant adverse impact on the environment, then the assessment normally

serves as the basis for a negative declaration, or Finding of No Significant

Impact (FONSI). Wastewater projects can affect the types and intensities

of land use by providing facilities to accommodate new development. The

location of new or expanded facilities affects the location of new develop-

ment. With limited public funds, a decision to finance a specific facility

limits funds for other facilities locally or in other areas and for similar or

other purposes. A compatible relationship needs to exist between the

potential growth-accommodating effects of facilities and the ability of a

region to support additional growth.

The assessment should address relative impacts of population growth

on natural resources such as air and water, and on visual conditions, com-

munity characteristics, archaeology, and other cultural values. It should

clearly illustrate the range of impacts resulting from various growth lev-

els, ranging from “no-growth” or “no project” to build-out.

Socioeconomic effects, employment, availability of housing, and the

costs of providing projected populations with other public services and

utilities should be assessed. Those long-term environmental goals which

conflict with economic needs must also be identified in assessment of sec-

ondary impacts.

An EA is an environmental report prepared expressly to determine

whether a proposed action requires the preparation of an environmental

impact statement. The EA may be based on procedures such as checklists,

matrices, networks, overlays, and specific studies. The environmental

assessment should:

• Describe the proposed action.

• Describe the environment to be affected.

18 GRAVITY SANITARY SEWER DESIGN AND CONSTRUCTION

• Identify all relevant environmental impact areas.

• Evaluate the potential environmental impacts.

• Identify adverse impacts that cannot be avoided should the action

be implemented.

• Identify irreversible and irretrievable commitments of resources.