348

337

330

325

Contents

©2017PACCARInc-AllRightsReserved

Thismanualillustratesanddescribestheoperationoffeaturesorequipmentwhichmaybeeitherstandardoroptionalon

thisvehicle.Thismanualmayalsoincludeadescriptionoffeaturesandequipmentwhicharenolongeravailableorwere

notorderedonthisvehicle.Pleasedisregardanyillustrationsordescriptionsrelatingtofeaturesorequipmentwhichare

notonthisvehicle.

PACCARreservestherighttodiscontinue,changespecications,orchangethedesignofitsvehiclesatanytime,without

noticeandwithoutincurringanyobligation.

TheinformationcontainedinthismanualisproprietarytoPACCAR.Reproduction,inwholeorinpart,byanymeansisstrictly

prohibitedwithoutpriorwrittenauthorizationfromPACCARInc.

SAFETY

INTRODUCTION

HowtoUseThisManual.............1-3

HowtoFindWhatYouWant...........1-3

SafetyAlerts..................1-4

VehicleSafety.................1-6

ASpecialWordAboutRepairs..........1-8

AdditionalSourcesofInformation.........1-9

CABANDFRAMEACCESS

Safety....................1-11

DoorLockandKeys..............1-12

RemoteKeylessEntry(RKE)..........1-13

ClimbingOntotheDeckPlate.........1-14

GETTINGTOYOURENGINE

HoodHoldDowns...............1-16

HoodTilt...................1-17

HoodSafetyCable..............1-18

(03/17)Y53-6060-1C11-1

1

SAFETY

SEATSANDRESTRAINTS

Introduction.................1-20

SafetyRestraintBelts.............1-21

TetherBelts.................1-24

Komfort-Latch®Feature............1-25

DuringPregnancy...............1-26

BeltDamageandRepair............1-27

SafetyRestraintTips.............1-27

START-UP

Introduction.................1-29

SafeVehicleOperation............1-29

VehicleLoading................1-30

EmergencyEquipment............1-31

Driver'sCheckList..............1-32

1-2Y53-6060-1C1(03/17)

1

INTRODUCTION

INTRODUCTION

HowtoUseThisManual

Thismanualcontainsuseful

informationforthesafeandefcient

operationofyourPeterbiltvehicle.

Italsoprovidesinformationon

maintainingyourvehicleinthebest

condition,withanoutlineforperforming

safetychecksandbasicpreventive

maintenanceinspections.

Wehavetriedtopresentthe

informationyou’llneedtolearnabout

yourvehicle’sfunctions,controls,and

operation—andtopresentitasclearly

aspossible.Wehopeyou’llndthis

manualeasytouse.

Therewillbetimeswhenyouneedto

takethismanualoutofyourPeterbilt.

Whenyoudo,pleasebesuretoreturn

ittothecabwhenyouarenished

usingit.Thatwayitwillbetherewhen

youneeditthenexttimeorwhenyou

passthevehicleontothenextuser.

HowtoFindWhatYouWant

Thereareseveraltoolsbuiltintothis

manualtohelpyoundwhatyouneed

quicklyandeasily.

FirstistheQuickTableofContents.

Locatedatthefrontofthemanual,this

liststhemainsubjectscoveredand

givessectionnumberswhereyoucan

ndthesesubjects.UsetheQuick

TableofContentstondinformation

onalargesubjectlike"Maintenance."

Cross-referencedcitationsalsohelp

yougettheinformationyouneed.If

someotherpartofthemanualcontains

furtherinformationonthesubjectyou

arereadingabout,we’llindicatethat

inacross-referencelikethis:(See

Driver’sCheckListonpage1-32).You

won’thavetogosearchingformore

information.

Finallyyou’llndahelpfulSubject

Index.It’sinthebackofthemanual

(03/17)Y53-6060-1C11-3

1

INTRODUCTION

andalphabeticallyliststhesubjects

covered.Soifyouwantinformationon

brakes,forexample,justlookunder

BrakeintheSubjectIndex.You’llnd

allthepageslistedwherebrakesor

brakingarediscussed.

SafetyAlerts

Pleasereadandfollowallofthe

safetyalertscontainedinthismanual.

Theyarethereforyourprotection

andinformation.Thesealertscan

helpyouavoidinjurytoyourself,your

passengers,andhelppreventcostly

damagetothevehicle.Safetyalerts

arehighlightedbysafetyalertsymbols

andsignalwordssuchas"WARNING",

"CAUTION",or"NOTE".Pleasedonot

ignoreanyofthesealerts.

WARNING

WARNING!

Thesafetymessagefollowingthis

symbolandsignalwordprovidesa

warningagainstoperatingprocedures

whichcouldcausedeathorpersonal

injury.Theycouldalsocause

equipmentorpropertydamage.The

alertwillidentifythehazard,howto

avoidit,andtheprobableconsequence

ofnotavoidingthehazard.

1-4Y53-6060-1C1(03/17)

1

INTRODUCTION

Example:

WARNING!

Donotcarryadditionalfuelcontain-

ersinyourvehicle.Fuelcontainers,

eitherfullorempty,mayleak,ex-

plode,andcauseorfeedare.Do

notcarryextrafuelcontainers.Even

emptyonesaredangerous.Failure

tocomplymayresultindeathorper-

sonalinjury.

CAUTION

CAUTION

Thesafetyalertfollowingthissymbol

andsignalwordprovidesacaution

againstoperatingprocedureswhich

couldcauseequipmentorproperty

damage.Thealertwillidentifythe

hazard,howtoavoidit,andthe

probableconsequenceofnotavoiding

thehazard.

Example:

CAUTION

Continuingtooperateyourvehi-

clewithinsufcientoilpressurewill

causeseriousenginedamage.Fail-

uretocomplymayresultinequip-

mentorpropertydamage.

NOTE

NOTE

Thealertfollowingthissymboland

signalwordprovidesimportant

informationthatisnotsafetyrelated

butshouldbefollowed.Thealert

willhighlightthingsthatmaynotbe

obviousandisusefultoyourefcient

operationofthevehicle.

Example:

NOTE

Pumpingtheacceleratorwillnotas-

sistinstartingtheengine.

(03/17)Y53-6060-1C11-5

1

INTRODUCTION

VehicleSafety

WARNING!

Donotdrinkalcoholanddrive.Your

reexes,perceptions,andjudgment

canbeaffectedbyevenasmall

amountofalcohol.Youcouldhavea

seriousorevenfatalaccident,ifyou

driveafterdrinking.Pleasedonot

drinkanddriveorridewithadriver

whohasbeendrinking.Failureto

complymayresultindeath,per-

sonalinjury,equipmentorproperty

damage.

WARNING!

Donottextanddrive.Yourreac-

tiontime,perceptionsandjudgment

canbeaffectedwhiletextingorus-

inganyotherformofmobilemes-

sagingwhiledriving.Failuretocom-

plymayresultindeath,personalin-

jury,equipmentorpropertydamage.

Makesureyourvehicleisintop

workingconditionbeforeheading

outontheroad,itistheresponsible

driver'sdutytodoso.Inspectthe

vehicleaccordingtotheDriver'sCheck

Listbeginningonpage1-32.

Everynewvehicleisdesignedto

conformtoallFederalMotorVehicle

SafetyStandardsapplicableatthetime

ofmanufacture.Evenwiththesesafety

features,continuedsafeandreliable

operationdependsgreatlyupon

regularvehiclemaintenance.Follow

themaintenancerecommendations

foundinPreventiveMaintenanceon

page5-9.Thiswillhelppreserveyour

investment.

Keepinmindthatevenawell

maintainedvehiclemustbeoperated

withintherangeofitsmechanical

capabilitiesandthelimitsofitsload

ratings.SeetheWeightRatingslabel

onthedriver'sdooredge.

Safedrivingisonlypossiblewiththe

properconcentrationonthedriving

task.Keepdistractiontoaminimumto

improveyourconcentration.Examples

ofdistractionsmayincluderadio

controls,GPSnavigationcontrols,

cellulartelephonecalls,cellulartext

messages,readingorreachingfor

somethingontheoor.Minimizing

yourdistractionswillimprovesafe

drivingandwillhelpavoidanaccident

involvingdeathorpersonalinjury.

Beawareoflocalregulationsthatmay

prohibittheuseofcellulartelephones

whiledriving.Inadditiontobeingan

unsafepractice,itmaybeagainstlocal

orfederalordinancestousecellular

deviceswhileoperatingthevehicle.

Thismanualisnotatrainingmanual.

Itcannottellyoueverythingyouneed

toknowaboutdrivingyourvehicle.For

thatyouneedagoodtrainingprogram

ortruckdrivingschool.Ifyouhavenot

1-6Y53-6060-1C1(03/17)

1

INTRODUCTION

beentrained,getthepropertraining

beforeyoudrive.Onlyqualieddrivers

shoulddrivethisvehicle.

CaliforniaProposition65Warning

•Dieselengineexhaustandsome

ofitsconstituentsareknownto

theStateofCaliforniatocause

cancer,birthdefects,andother

reproductiveharm.

•Otherchemicalsinthisvehicle

arealsoknowntotheStateof

Californiatocausecancer,birth

defectsorotherreproductive

harm.

•Batteryposts,terminals,and

relatedaccessoriescontainlead

andleadcompounds,chemicals

knowntotheStateofCalifornia

tocausecancerandreproductive

harm.Washhandsafterhandling.

DataRecorder

CaliforniaVehicleCode-Section

9951-DisclosureofRecordingDevice

Yourvehiclemaybeequippedwithone

ormorerecordingdevicescommonly

referredtoas"eventdatarecorders

(EDR)"or"sensinganddiagnostic

modules(SDM)".Ifyouareinvolvedin

anaccident,thedevice(s)mayhave

theabilitytorecordvehicledatathat

occurredjustpriortoand/orduringthe

accident.Foradditionalinformationon

yourrightsassociatedwiththeuseof

thisdata,contact

•theCaliforniaDepartmentofMotor

Vehicles-LicensingOperations

Division

–or–

•http://www.dmv.ca.gov/

pubs/vctop/d03_6/vc9951.htm

(03/17)Y53-6060-1C11-7

1

INTRODUCTION

EnvironmentalProtection

WARNING!

Dieselengineexhaustandsome

ofitsconstituentsareknowntothe

StateofCaliforniatocausecancer,

birthdefects,andotherreproduc-

tiveharm.Otherchemicalsinthis

vehiclearealsoknowntotheState

ofCaliforniatocausecancer,birth

defectsorotherreproductiveharm.

Thiswarningrequirementisman-

datedbyCalifornialaw(Proposition

65)anddoesnotresultfromany

changeinthemannerinwhichvehi-

clesaremanufactured.

Someoftheingredientsinengine

oil,hydraulicoil,transmissionand

axleoil,enginecoolant,dieselfuel,

airconditioningrefrigerant(R12,

R134a,andPAGoil),batteries,etc.,

maycontaminatetheenvironmentif

spilledornotdisposedofproperly.

Contactyourlocalgovernmentagency

forinformationconcerningproper

disposal.

ASpecialWordAbout

Repairs

WARNING!

Donotattemptrepairworkwithout

sufcienttraining,servicemanuals,

andthepropertools.Youcouldbe

killedorinjured,oryoucouldmake

yourvehicleunsafe.Doonlythose

tasksyouarefullyqualiedtodo.

Yourdealer’sservicecenteristhebest

placetohaveyourvehiclerepaired.

Youcannddealersalloverthe

countrywiththeequipmentandtrained

personneltogetyoubackontheroad

quickly—andkeepyouthere.

Yourvehicleisacomplexmachine.

Anyoneattemptingrepairsonitneeds

goodmechanicaltrainingandthe

propertools.Ifyouaresureyou

havetheserequirements,thenyou

canprobablyperformsomerepairs

yourself.However,allwarrantyrepairs

1-8Y53-6060-1C1(03/17)

1

INTRODUCTION

mustbeperformedbyanauthorized

servicefacility.Ifyouaren’tan

experiencedmechanic,ordon’thave

therightequipment,pleaseleaveall

repairstoanauthorizedservicefacility.

Theyaretheonesequippedtodothe

jobsafelyandcorrectly.

MaintenanceManuals.Ifyoudo

decidetodoanycomplexrepairwork,

you’llneedthemaintenancemanuals.

Orderthemfromyourauthorized

dealer.PleaseprovideyourChassis

SerialNumberwhenyouorder,tobe

sureyougetthecorrectmanualsfor

yourvehicle.Allowaboutfourweeks

fordelivery.Therewillbeachargefor

thesemanuals.

FinalChassisBillofMaterial.A

complete,non-illustratedcomputer

printoutlistingofthepartsusedto

custom-buildyourvehicleisavailable

throughthedealerfromwhomyou

purchasedyourvehicle.

WARNING!

Modifyingyourvehiclecanmake

itunsafe.Somemodicationscan

affectyourvehicle'selectricalsys-

tem,stability,orotherimportant

functions.Beforemodifyingyour

vehicle,checkwithyourdealerto

makesureitcanbedonesafely.

Impropermodicationscancause

deathorpersonalinjury.

AdditionalSourcesof

Information

InstalledEquipment-Operator's

Manuals

Majorcomponentsuppliersalsosupply

operationmanualsspecictotheir

products.Additionalmanualsand

otherpiecesofliteratureareincludedin

thegloveboxliteraturepackage.Look

forinformationonproductssuchas

theengine,driver'sseat,transmission,

axles,wheels,tires,ABS/ESC(if

applicable),radio,5thwheel.Ifyou

aremissingthesepiecesofliterature,

askyourDealerforcopies.

(03/17)Y53-6060-1C11-9

1

INTRODUCTION

OtherSources

Anotherplacetolearnmoreabout

truckingisfromlocaltruckdriving

schools.Contactonenearyoutolearn

aboutcoursestheyoffer.

Federalandstateagenciessuch

asthedepartmentoflicensingalso

haveinformation.TheInterstate

CommerceCommissioncangive

youinformationaboutregulations

governingtransportationacrossstate

lines.

1-10Y53-6060-1C1(03/17)

1

CABANDFRAMEACCESS

CABANDFRAME

ACCESS

Safety

WARNING!

Alwaysreinstallstepsbeforeenter-

ingthecaboraccessingthedeck

plate.Withoutstepsyoucouldslip

andfall.Failuretocomplymayre-

sultindeathorpersonalinjury.

Becarefulwheneveryougetintoorout

ofyourvehicle’scab.Alwaysmaintain

atleastthreepointsofcontactwith

yourhandsonthegrabhandlesand

yourfeetonthesteps.

WARNING!

Jumpingoutofthecaborgetting

intothecabwithoutpropercaution

isdangerous.Youcouldslipand

fall,whichcouldleadtodeathor

personalinjury.Keepstepsclean.

Cleananyfuel,oil,orgreaseoffof

thestepsbeforeenteringthecab.

Usethestepsandgrabhandles

provided,andalwayskeepatleast

threepointsofcontactbetweenyour

handsandfeetandthetruck.Al-

waysfacetowardthevehiclewhen

enteringorexitingthecabandlook

whereyouaregoing.

Thefollowingpictureshowsthebest

waytoenterandexitaConventional

Cab.

(03/17)Y53-6060-1C11-11

1

CABANDFRAMEACCESS

DoorLockandKeys

DoorLock

Doorscanbelockedfromtheinsideby

usingthelockbutton.Closethedoor

thenpushthebuttondowntolock.

Doorsautomaticallyunlockwhenyou

openthemfrominside,andcanbe

lockedfromtheoutsidewiththekeyor

theoptionalremotekeylessentrykey

fob.

WARNING!

Toreducethechanceofdeathor

personalinjury,alwayslockthe

doorswhiledriving.Alongwithusing

thelapshoulderbeltsproperly,lock-

ingthedoorshelpspreventdoors

frominadvertentlyopeningandoc-

cupantsfrombeingejectedfromthe

vehicle.

Tolockorunlockthedoorsfrom

outsidethecab,insertthekeyinthe

lock.Turnthekeytowardtherearto

lock;forwardtounlock.

Keys

Thesamekeytsyourignition,doors,

andsleeperluggagecompartment.

Frame-mountedtoolboxlocksand

lockingfueltankcapseachhave

individualkeys.

1-12Y53-6060-1C1(03/17)

1

CABANDFRAMEACCESS

RemoteKeylessEntry(RKE)

(Optional)

Thisvehiclemaybeequippedwitha

RemoteKeylessEntry(RKE)system

thataddssecurityandconvenience

toyourvehicle.Thesystemwill

lockorunlockthedriver’sdoorand

passenger’sdoorwiththekeyfoband

alertyouwithparkinglightswhenthe

selecteddoorsarelockedorunlocked.

Thesystemincludestwokeyfobsthat

providesecurerollingcodetechnology

thatpreventssomeonefromrecording

theentrysignal.

NOTE

FCCID:L2C0031TIC:3432A-

0031TFCCID:L2C0032RIC:

3432A-0032RThisdevicecomplies

withPart15oftheFCCRulesand

withRSS-210ofIndustryCanada.

Operationissubjecttothefollowing

twoconditions:(1)Thisdevicemay

notcauseharmfulinterference,and

(2)Thisdevicemustacceptanyin-

terferencereceived,includinginter-

ferencethatmaycauseundesired

operation.Changesormodica-

tionsnotexpressivelyapprovedby

thepartyresponsibleforcompliance

couldvoidtheuser'sauthoritytoop-

eratetheequipment.Theterm"IC:"

beforetheradiocerticationnumber

onlysigniesthatIndustryCanada

technicalspecicationsweremet.

Operation

ToUnlockTheDriver’sDoor

PresstheUNLOCKbuttononce.The

driver'sdoorwillunlockandtheparking

lightswillcomeonfor40seconds.

ToUnlockThePassenger’sDoor

PresstheUNLOCKbuttononceand

pressagainwithin5seconds.The

passengerdoorwillunlock.

ToLockAllDoors

PresstheLOCKbutton.Thedoorswill

lockandtheparkinglightswillcome

onfor2seconds.Ifthedoorsareopen

theywillnotlock.Therangeofthe

RKEsystemshouldbeapproximately

30ft.Thiswillbereducedifitis

operatedclosetootherRFsources

suchasTV/radiotransmittersandcell

towers.

(03/17)Y53-6060-1C11-13

1

CABANDFRAMEACCESS

Batteries

ThekeyfobusesoneCR2032,

3Vbattery.Batteriesshouldlast

approximatelythreeyears,depending

onuse.Consistentlyreducedrange

isanindicatorthatthebatteryneeds

replacement.Batteriesareavailable

atmostdiscount,hardwareanddrug

stores.

Thebatterycanbeaccessedby

removingthecoverofthekeyfob.

Afteranewbatteryisinstalled,the

keyfobmustbesynchronizedwiththe

vehicle.

Synchronization

Thekeyfobmayneedtobe

synchronizedtothetruckwhenthe

batteryisreplacedorwhenthekeyfob

hasnotbeenusedforanextended

periodoftime.

ToSynchronizeAKeyFob

1.Holdthekeyfobnearthereceiver

whichislocatedbehindthe

speedometerandtachometer.

2.PressandholdboththeLockand

Unlockbuttonsatthesametime

forapproximately7seconds.

3.Whenthekeyfobis

resynchronized,thedoors

willlockthenimmediatelyunlock.

4.Ifthefobfailstosynchronize,

itcouldbeprogrammedtoa

differenttruckorcouldhavefailed.

Contactyourdealertore-program

yourkeyfob.

ClimbingOntotheDeck

Plate

WARNING!

Whenyouareclimbingontoand

offthedeckplate,maintainatleast

threepointsofcontactwithyour

handsonthegrabhandlesandyour

feetonthesteps.Alwaysfaceto-

wardthevehiclewhenenteringor

exitingthecabandlookwhereyou

aregoing.Failuretocomplymay

resultindeathorpersonalinjury.

WARNING!

Whensteppingontoasurfacetoen-

terthecaboraccessthedeckplate,

onlyusethestepsandgrabhan-

dlesinstalledanddesignedforthat

purpose.Failuretousetheproper

stepsandgrabhandlescouldcause

afallwhichmayresultindeathor

personalinjury.

1-14Y53-6060-1C1(03/17)

1

CABANDFRAMEACCESS

WARNING!

Keepstepsclean.Cleananyfuel,

oil,orgreaseoffthestepsbefore

enteringthecaboraccessingthe

deckplate.Steppingonaslippery

surfacecancauseafallwhichmay

resultindeathorpersonalinjury.

WARNING!

Alwaysreinstallstepsbeforeenter-

ingthecaboraccessingthedeck

plate.Withoutstepsyoucouldslip

andfall.Failuretocomplymayre-

sultindeathorpersonalinjury.

NOTE

Anyalteration(addingbulkheads,

headacheracks,toolboxes,etc.)

behindthecabthataffectstheuti-

lizationofinstalledgrabhandles,

deckplates,orframeaccesssteps

shouldcomplywithFederalMotor

CarrierSafetyRegulation399.

Thefollowingpicturesshowyouthe

rightwaytogetonandoffthearea

behindyourcab.

Holdhandlesasyoustepup.

Maintainthreepointsofcontact.

(03/17)Y53-6060-1C11-15

1

GETTINGTOYOURENGINE

GETTINGTOYOUR

ENGINE

HoodHoldDowns

Thehoodissecuredinitsclosed

positionbyanexternallatchon

eachside.Theselatchesserveas

holddownsandkeepthehoodfrom

openingunexpectedly.

CAUTION

Ifyoudonotlatchthehoodsecurely,

itcouldopenduringoperationand

causevehicledamage.Besureto

latchthehoodsecurelybeforemov-

ingthevehicle.

Toopenthehood,unlatchbothofthe

hoodholddowns.

1.HoodLatchintheClosedPosition

2.PullLatchtoOpen

1-16Y53-6060-1C1(03/17)

1

GETTINGTOYOURENGINE

3.PullUptoSeparate 4.HoodLatchintheOpenPosition

HoodTilt

WARNING!

Apivotinghoodcouldhurtsome-

oneorbedamageditself.Before

openingorclosingthehood,besure

therearenopeopleorobjectsinthe

way.Failuretostandinapositionof

safetycancausedeathorpersonal

injury.

WARNING!

Beforeopeningthehood,makesure

yourfootingissecureandstable.

Failuretodosomaycausethehood

tocloseuncontrollablywhichmay

resultindeathorpersonalinjury.

Putonehandonthehoodhandle(just

abovethePeterbiltemblem),onefoot

onthebumper,andonefootonthe

ground.Tiltthehoodforward.

(03/17)Y53-6060-1C11-17

1

GETTINGTOYOURENGINE

Pullwithhandfromhere

Locatethehoodsafetycableasshown

inthefollowingsectionandattachitto

thehookonthehood.

Toclosethehood,youmustrst

detachthehoodsafetycablefromthe

hookonthehood.

WARNING!

Beforeclosingthehood,besurethe

areaisclear—nopeopleorobjects

areintheway.Failuretodosomay

resultindeathorpersonalinjury.

CAUTION

Toavoidhooddamagewhenclosing

thehood,detachthesafetycable

fromthehookonthehoodbefore

closingthehood.

HoodSafetyCable

Thehoodisequippedwithahood

safetycable.Thecableisonthe

driver’ssideoftheradiator.Unwind

thecablebypullingonitandattach

theloopofthecabletothehookon

thehood.

WARNING!

Alwaysattachthehoodsafetycable

tokeepahoodopenanytimeany-

onegetsunderahoodforanyrea-

son.Failuretodosomayallowthe

hoodtofallunexpectedlyresultingin

deathorpersonalinjury.

1-18Y53-6060-1C1(03/17)

1

GETTINGTOYOURENGINE

Safetycableinitsstoredposition

Safetycableinitsattachedposition

(03/17)Y53-6060-1C11-19

1

SEATSANDRESTRAINTS

SEATSAND

RESTRAINTS

Introduction

Thissectioncoverstheoperation

andsafeuseofyourseats.For

furtherinformationonfeaturesand

adjustmentoftheseat,seethe

manufacturer'sServiceandOperation

Manualincludedwiththevehicle.

SeatAdjustment

WARNING!

Donotadjustthedriver'sseatwhile

thevehicleismoving.Theseat

couldmovesuddenlyandunexpect-

edlyandcancausethedriverto

losecontrolofthevehicle.Makeall

adjustmentstotheseatwhilethe

vehicleisstopped.Afteradjusting

theseatandbeforedrivingoff,al-

wayschecktoensurethattheseat

isrmlylatchedinposition.Failure

tocomplymayresultindeath,per-

sonalinjuryorpropertydamage.

WARNING!

Beforedrivingorridinginvehi-

cle,ensurethatthereisadequate

headclearanceatmaximumupward

travelofseat.Injurymayoccurif

headclearanceisnotadequate.

Failuretocomplymayresultindeath

orpersonalinjury.

StandardDriver'sSeat

Thestandarddriver'sseatcanbe

adjustedforwardandrearward.These

movementsareeachcontrolledby

leverslocatedontheFRONTofthe

seat.

Driver'sSeatwithAirSuspension

(Option)

WARNING!

Beforedrivingorridinginthevehi-

cle,besurethatthereisadequate

headclearanceatmaximumupward

travelofseat.Seriousinjurymay

occurifheadclearanceisnotade-

quate.

Thedriver'sseatwithairsuspension

canbeadjustedusingthecontrols

pictured.

1-20Y53-6060-1C1(03/17)

1

SEATSANDRESTRAINTS

SafetyRestraintBelts

Safetybeltshaveproventobethe

singlemosteffectivemeansavailable

forreducingthepotentialforeither

deathorpersonalinjuryinmotor

vehicleaccidents.Unbeltedriders

couldbethrownintothewindshield

orotherpartsofthecaborcouldbe

thrownoutofthecab.Theycould

strikeanotherperson.Injuriescanbe

muchworsewhenridersareunbelted.

Alwaysfastenyourseatbeltandbe

sureanyoneridingwithyoudoesthe

same.Therefore,readthefollowing

instructionsandalwaysobserveuser

warningspertainingtosafetybelts.

WARNING!

Donotdrivevehiclewithoutyour

seatbeltandyourridersbeltsfas-

tened.Ridingwithoutasafetybelt

properlyfastenedcanleadtodeath

orpersonalinjuryinanemergency.

WARNING!

Invehiclesequippedwithpassenger

seatswivelfunction,theseatbelts

willonlyperformtheirintendedfunc-

tionwhentheseatisfacingforward.

Failuretocomplycanleadtodeath

orpersonalinjuryinanemergency.

Yourvehicleisequippedwithaseatbelt

indicatorinthewarninglightdisplay

(03/17)Y53-6060-1C11-21

1

SEATSANDRESTRAINTS

abovethespeedometer/tachometer

(see"SeatBelt,Fasten"onpage3-23).

Lap/ShoulderBelt

Thecombinationlap-shoulderbeltis

equippedwithalockingmechanism.

Thesystemadjustsautomaticallytoa

person'ssizeandmovementsaslong

asthepullonthebeltisslow.

Hardbrakingoracollisionlocksthe

belt.Thebeltwillalsolockwhen

drivingupordownasteephillorina

sharpcurve.

Tofastenthebelt:

1.Graspthebelttongue.

2.Pullbeltinacontinuousslow

motionacrossyourchestandlap.

3.Insertbelttongueintobuckleon

inboardsideofseat.

4.Pushdownuntilthetongueis

securelylockedwithanaudible

click.

5.Pullbelttocheckforproper

fasteningandadjustment,as

follows:

•Pullshouldersectiontomakesure

belttssnuglyacrossthechest

andpelvis.

•Thereshouldbelessthan1inch

(25mm)gapbetweenthebody

andthebelt.

•Theshoulderbeltmustbe

positionedovertheshoulder,it

mustneverrestagainsttheneck

orbewornunderthearm.

•Makesureanyslackiswoundup

ontheretractorandthatthebelt

isnottwisted.

Tounfastenthebelt:

1.Pushinthereleasebuttononthe

buckle.

2.Thebeltwillspringoutofthe

buckle.

1-22Y53-6060-1C1(03/17)

1

SEATSANDRESTRAINTS

Ifthebeltislocked,leanthebodyback

toremoveanytensioninthebelt.After

releasingthebelt,allowthebeltto

retractcompletelybyguidingthebelt

tongueuntilthebeltcomestoastop.

SafetyRestraintBelts

LapBelt

ShoulderBelt

CorrectIncorrect(toohighonhips)Correct(overarm)Incorrect(under

arm)

Incorrect(twisted)

(03/17)Y53-6060-1C11-23

1

SEATSANDRESTRAINTS

WARNING!

Properseatbeltadjustmentanduse

isimportanttomaximizeoccupant

safety.Failuretowearoradjust

thesafetybeltproperlymayresultin

deathorpersonalinjury.

TetherBelts

Thisvehiclemayhaveanexternal

tetherbeltinstalledwithaseat,instead

oftheinternaltetheringdevice.T ether

beltsaredesignedtorestraintheseat

intheeventofasuddenstoporan

accident.

Internaltetherbeltsdonotrequire

adjustment.

WARNING!

Donotremove,modify,orreplace

thetetherbeltsystemwithadiffer-

enttethersystem.Afailedormiss-

ingtetherbeltcouldallowtheseat

basetofullyextendintheeventof

anaccident.Failuretocomplymay

resultindeathorpersonalinjury.

WARNING!

Failuretoadjusttetherbeltsproperly

cancauseexcessivemovementof

theseatinanaccident.Tetherbelts

shouldbeadjustedsothattheyare

tautwhentheseatisinitsmostup-

wardandforwardposition.Failure

tocomplymayresultindeathorper-

sonalinjury.

1-24Y53-6060-1C1(03/17)

1

SEATSANDRESTRAINTS

Toadjustanexternaltetherbelt

•Makesurethatthetetherbeltis

attachedtothecaboorandseat

frame.Itshouldberoutedthrough

thebuckleoneachside.

•Oftentheattachmentsaremade

usingasplit-typehook.Makesure

bothhalvesofthehookarearound

theanchorbracket.

•Tolengthenthetether,turnthe

buckletoarightangletothe

webbing.Thenpullthebuckle.

Toshortenthetether,pullonthe

strap.

Komfort-Latch®Feature

Yourvehicleincludesafeature

designedtoeliminatecinchingand

provideimprovedsafetyandcomfort.

Cinchingistheconditionwhereabelt

becomescontinuallytighteraround

youduringarough,bouncyride.The

needforthisfeatureincreaseswith

roughroadconditions,particularlyover

longdistances.

Toeliminatecinching,simplyactivate

theKomfort-Latchfeaturelocated

ontheseatbeltwebbingatthe

appropriatetime.

1.Adjusttheseattoitsproperdriving

position.

2.Latchtheseatbelt.

3.Ifavailable,adjusttheseatbelt

heightadjustertoacomfortable

drivingposition.

4.Whileseatedappropriately,push

the"on"buttontoengagethe

KomfortLatch.

5.Learnforwardintheseatuntilyou

heara"click."

6.Returntonormaldrivingposition,

andtheKomfortLatchmaintains

thepresetamountoftensionrelief.

Todisengagethemechanism:

1.Unbuckletheseatbelt

2.Pressthe"OFF"buttonofthe

KomfortLatchortugonthe

shoulderstrap.

(03/17)Y53-6060-1C11-25

1

SEATSANDRESTRAINTS

Komfort-Latch®

Moreinformationandvideo

tutorialscanbefoundat:

www.clicktugsnug.com.

WARNING!

DonotsettheKomfortLatchwithtoo

muchslack.Toomuchslackmay

reducetheeffectivenessoftheseat

belt.Failuretocomplymayresultin

deathorpersonalinjury.

DuringPregnancy

Pregnantwomenshouldalwayswear

combinationlap/shoulderbelts.The

lapbeltportionmustbewornsnugly

andaslowaspossibleacrossthe

pelvis.Toavoidpressureonthe

abdomen,thebeltmustneverpass

overthewaist.Aproperlywornseat

beltmaysignicantlyreducetherisks

towomanandbabyintheeventofa

crash.

1-26Y53-6060-1C1(03/17)

1

SEATSANDRESTRAINTS

PregnantWomanwithBeltProperly

Worn

BeltDamageandRepair

Damagedbeltsinthecabmust

bereplaced.Beltsthathavebeen

stretched,cut,orwornoutmaynot

protectyouinanaccident.

Ifanyseatbeltisnotworkingproperly,

seeanAuthorizedServiceCenterfor

repairorreplacement.

Forfurtherinformationonseatbelts

andseatbeltmaintenance,seeSafety

RestraintSystem-Inspectiononpage

5-75.

SafetyRestraintTips

•Donotwearabeltoverrigidor

breakableobjectsinoronyour

clothing,suchaseyeglasses,

pens,keys,etc.,asthesemay

causeinjuryinanaccident.

•Anyauthorizedpersonsleeping

inyourvehiclewhileitismoving

shouldusethebunkrestraint.

•Anyauthorizedpersonsittingin

thesleeperareaonthesofabed

(ifequipped)whileitismoving

shouldwearaseatbelt.

•Aresponsibleoperatorseestoit

thateveryoneinthevehiclerides

orsleepssafely.Theoperator

isresponsibletoinformany

passengersorco-drivershowto

properlyusetheseatbeltsand

bunkrestraintinthevehicle.

•Donotstrapinmorethanone

personwitheachbelt.

(03/17)Y53-6060-1C11-27

1

SEATSANDRESTRAINTS

•Keepseatbeltandbunkrestraint

bucklesfreeofanyobstruction

thatmaypreventsecurelocking.

•Damagedorwornbeltsinthecab

orsleeper,subjectedtoexcessive

stretchforcesfromnormalwear,

mustbereplaced.Theymay

notprotectyouifyouhavean

accident.

•Anybeltsorrestraintsthathave

beensubjectedtoanaccident

shouldbeinspectedforanyloose

(attaching)hardwareordamaged

buckles.

•Ifbeltsshowdamagetoanypart

ofassembly,suchaswebbing,

bindings,bucklesorretractors,

theymustbereplaced.

•Donotallowsafetybelts(seat

orbunk)tobecomedamagedby

gettingcaughtindoor,bunkor

seathardware,orrubbingagainst

sharpobjects.

•Allbeltsmustbekeptcleanorthe

retractorsmaynotworkproperly.

•Neverbleachordyeseatorbunk

restraintbelts:chemicalscan

weakenthem.Do,however,keep

themcleanbyfollowingthecare

labelonthebelts.Letthemdry

completelybeforeallowingthem

toretractorbestowedaway.

•Makesuretheseatbeltsand

bunkrestraintoftheunoccupied

passengerseatorbunkisfully

wounduponitsretractoror

isstowed,sothatthebeltor

restrainttongueisinitsproperly

stowedposition.Thisreducesthe

possibilityofthetonguebecoming

astrikingobjectincaseofa

suddenstop.

•Donotmodifyordisassemblethe

seatbeltsorbunkrestraintinyour

vehicle.Theywillnotbeavailable

tokeepyouandyourpassengers

safe.

•Ifanyseatbeltorbunkrestraint

isnotworkingproperly,seean

authorizeddealerforrepairor

replacement.

1-28Y53-6060-1C1(03/17)

1

START-UP

START-UP

Introduction

Thefollowingsectioncoversstart-up

proceduresforgettingyourvehicle

readyfortheroad.

SafeVehicleOperation

Foryoursafety,aswellasthose

aroundyou,bearesponsibledriver:

•Ifyoudrinkalcohol,donotdrive.

•Donotdriveifyouaretired,ill,or

underemotionalstress.

Safedrivingisonlypossiblewiththe

properconcentrationonthedriving

task.Keepdistractiontoaminimumto

improveyourconcentration.Examples

ofdistractionsmayincluderadio

controls,GPSnavigationcontrols,

cellulartelephonecalls,cellulartext

messages,readingorreachingfor

somethingontheoor.Minimizing

yourdistractionswillimprovesafe

drivingandwillhelpavoidanaccident

involvingdeathorpersonalinjury.

Beawareoflocalregulationsthatmay

prohibittheuseofcellulartelephones

whiledriving.Inadditiontobeingan

unsafepractice,itmaybeagainstlocal

orfederalordinancestousecellular

deviceswhileoperatingthevehicle.

Muchhasgoneintothemanufacturing

ofyourvehicleincludingadvanced

engineeringtechniques,rigidquality

control,anddemandinginspections.

Thesemanufacturingprocesseswill

beenhancedbyyou,thesafedriver,

whoobservesthefollowing:

•Knowsandunderstandshowto

operatethevehicleandallits

controls.

•Maintainsthevehicleproperly.

•Usesdrivingskillswisely.

Formoreinformation,referto

DepartmentofTransportation

Regulation392.7,whichstatesthat

interstatecommercialmotorvehicles

arenottobedrivenunlessthedriveris

surethatcertainpartsandaccessories

areinworkingorder.

(03/17)Y53-6060-1C11-29

1

START-UP

WARNING!

Theuseofalcohol,drugs,andcer-

tainmedicationswillseriouslyim-

pairperception,reactions,anddriv-

ingability.Thesecircumstancescan

substantiallyincreasetheriskofan

accident.Failuretocomplymayre-

sultindeath,personalinjury,equip-

mentorpropertydamage.

Donotdrinkalcoholanddrive.Your

reexes,perceptions,andjudgment

canbeaffectedbyevenasmall

amountofalcohol.Youcouldhavea

seriousorevenfatalaccident,ifyou

driveafterdrinking.Pleasedonot

drinkanddriveorridewithadriver

whohasbeendrinking.

WARNING!

Donottextanddrive.Yourreac-

tiontime,perceptionsandjudgment

canbeaffectedwhiletextingorus-

inganyotherformofmobilemes-

sagingwhiledriving.Failuretocom-

plymayresultindeath,personalin-

jury,equipmentorpropertydamage.

VehicleLoading

Compareyourvehicle'sloadcapacity

withthetotalloadyouarecarrying.If

adjustmentsneedtobemade,make

them,donotdriveanoverloaded

vehicle.Ifyouareoverloadedoryour

loadhasshifted,yourvehiclemaybe

unsafetodrive.

WARNING!

Donotexceedthespeciedloadrat-

ing.Overloadingcanresultinloss

ofvehiclecontrol,eitherbycausing

componentfailuresorbyaffecting

vehiclehandling.Exceedingload

ratingscanalsoshortentheservice

lifeofthevehicle.Failuretocomply

mayresultindeathorpersonalin-

jury.

Thegrossvehicleweightrating

(GVWR),orthemaximumfront

andreargrossaxleweightratings

(GAWRs)aredeterminedbythe

1-30Y53-6060-1C1(03/17)

1

START-UP

componentsinstalledfromthefactory

ontothevehicleandtheirdesigned

specications.(Axleweightratingsare

listedonthedriver'sdooredge.)

Thefollowingaresomedenitionsof

weightyoushouldknow:

GVWR:istheGrossVehicleWeight

Rating.ThisistheMAXIMUM

WEIGHTyourvehicleisallowedto

carry,includingtheweightoftheempty

vehicle,loadingplatform,occupants,

fuel,andanyload.Neverexceedthe

GVWRofyourvehicle.

GCW:istheactualcombinedweight,

orGrossCombinationWeight(GCW),

ofyourvehicleanditsload:vehicle,

plustrailer(s),pluscargo.

GAWR:istheGrossAxleWeight

Rating.Thisisthetotalweightthat

oneaxleisdesignedtotransmittothe

ground.Youwillndthisnumberlisted

onthedriver'sdooredge.

LoadDistribution:besureanyload

youcarryisdistributedsothatnoaxle

hastosupportmorethanitsGAWR.

WARNING!

Anunevenlydistributedloadora

loadtooheavyoveroneaxlecanaf-

fectthebrakingandhandlingofyour

vehicle,whichcouldresultinanac-

cident.Evenifyourloadisunderthe

legallimits,besureitisdistributed

evenly.Failuretocomplymayresult

indeath,personalinjury,equipment

orpropertydamage.

EmergencyEquipment

Itisgoodpracticetocarryan

emergencyequipmentkitinyour

vehicle.Oneday,ifyouhavea

roadsideemergency,youwillbeglad

thefollowingitemsarewithyou:

•windowscraper

•snowbrush

•containerorbagofsandorsalt

•emergencylight

•warningtriangles

•smallshovel

•rstaidkit

•reextinguisher

•vehiclerecoveryhitches(see

VehicleRecoveryGuidelineson

page2-12fordetails).

(03/17)Y53-6060-1C11-31

1

START-UP

Driver'sCheckList

Tokeepyourvehicleintopshapeand

maintainahighlevelofsafetyforyou,

yourpassengers,andyourload,make

athoroughinspectioneverydaybefore

youdrive.Youwillsavemaintenance

timelater,andthesafetychecks

couldhelppreventaseriousaccident.

Pleaseremember,too,thatFederal

MotorCarrierSafetyRegulation392.7

requiresapre-tripinspectionandso

docommercialtruckingcompanies.

Youarenotexpectedtobecomea

professionalmechanic.Thepurpose

ofyourinspectionsistondanything

thatmightinterferewiththesafeand

efcienttransportationofyourself,any

passengers,andyourload.Ifyoudo

ndsomethingwrongandcannotxit

yourself,haveanauthorizeddealeror

qualiedmechanicrepairyourvehicle

rightaway.

Thefollowingoperationsaretobe

performedbythedriver.Performing

thesechecksandfollowingthe

maintenanceproceduresinthis

manualwillhelpkeepyourvehicle

runningproperly.

ApproachingYourVehicle

•Checktheoverallappearanceand

condition.Arewindows,mirrors,

andlightscleanandunobstructed?

•Checkbeneaththevehicle.Are

theresignsoffuel,oil,orwater

leaks?

•Checkfordamaged,loose,or

missingparts.Arethereparts

showingsignsofexcessivewear

orlackoflubrication?Havea

qualiedmechanicexamineany

questionableitemsandrepair

themwithoutdelay.

•Checkyourload.Isitsecured

properly?

1-32Y53-6060-1C1(03/17)

1

START-UP

DailyChecks

EngineCompartmentChecks-Daily

1.EngineFluidLevels-addmoreif

necessary.

a.Engineoil

b.Coolant(checkwhileengine

iscold)

c.Powersteeringuidlevel

2.EngineBelt-checktensionand

conditionofbelts.

a.SeeAccessoryDriveBelts

onpage5-102forfurther

informationoncheckingbelt

tension.

NOTE

Deectionshouldbeonebeltthick-

nessforeachfootdistancebetween

thepulleycenters.

b.Replacebeltsthatarecracked

tornorbroken.

3.FuelFilter/WaterSeparator

Draining-checkanddrain.

Dependingonthefuelstorage

facility,morefrequentdraining

mayberequired.

4.Windshieldwasherreservoiruid

level-llifnecessary.

5.BatteryCables-checkthe

conditionofthebatteryand

alternatorcablesforsignsof

changorrubbing.Makesure

thatallclamps(straps)holdingthe

cablesarepresentandingood

workingorder.

6.Hoodclosedbeforeenteringcab.

Isitlatchedproperly?

7.Checkbrakelinesandhoses.

8.Checkthesteeringcomponents

(pitmanarm,draglink,power

steeringhoses,etc.).

ChassisandCabChecks-Daily

Beforeenteringthecabandoperating

thevehicle,checkthefollowing

equipmentforpropermaintenance:

1.Lights-areanyexteriorlights

crackedordamaged?

2.WindowsandMirrors-arethey

cleanandadjustedproperly?

3.TiresandWheels-arethey

inatedproperly?Areallwheel

capnutsinplaceandtorqued

properly-tightenifnecessary.

Checkfrontwheelbearingoil

levels.Inspectalltiresandwheels

fordamage-correctiffound.

4.Suspension-checkforlooseor

missingfasteners.Checkdamage

tospringsorothersuspension

partssuchascracks,gouges,

distortions,bulgesorchang.

(03/17)Y53-6060-1C11-33

1

START-UP

5.BrakeComponents-checklines,

linkages,chambers,parkingand

servicebrakeoperation.

6.Ifyourtruckhashydraulicbrakes,

check:

°thebrakesystemforleaks

°hydrauliclinesforcracksor

kinks

°calipersforleaks

7.AirSystem-arethereleaks?

AirTanks-drainwaterfromallair

tanks.Makesurethedraincocks

areclosed.Thisprocedureisalso

requiredforairsuspensiontanks

equippedwithautomaticdrain

valves.

ForfurtherdetailsSeeUsingthe

BrakeSystemonpage4-24.

8.StepsandHandholds-check

forwornsurfacesandlooseor

missingfasteners(whichincludes

anyfueltanksteps).

9.FluidTanks(Fuel,DEF,etc.)-

checkunderneaththevehiclefor

signsofuidleaks.Ifanyare

found,correctbeforeoperatingthe

vehicle.

10.FuelT ankHardware-arethe

tanksllcapssecure?Arethe

tankstrapstight?Isthestrap

webbinginplace?

WARNING!

Dieselfuelinthepresenceofanig-

nitionsource(suchasacigarette)

couldcauseanexplosion.Donotre-

moveafueltankcapnearanopen

ame.Useonlythefueland/oraddi-

tivesrecommendedforyourengine.

Amixtureofgasolineoralcoholwith

dieselfuelincreasesthisriskofex-

plosion.Failuretocomplymayresult

indeath,personalinjury,equipment

orpropertydamage.SeeRefueling

onpage4-67,formoreinformation.

11.TrailerConnections-arethey

secureandthelinesclear?If

theyarenotbeingused,arethey

storedproperly?

a.Isthetrailersparewheel

secureandinated?

b.Isthelandinggearupandthe

handlesecured?

12.Checkthefthwheel.Isthe

kingpinlocked?

a.Istheslidingfthwheel

locked?

CabInterior-Daily

1.Seat-adjusttheseatforeasy

reachofcontrolsandvisibility.

2.SeatBelts-fastenandadjust

safetyrestraintbelts(whichmay

includerestraintsinthesleeper).

3.SteeringColumn-adjustforeasy

reachandvisibility.

1-34Y53-6060-1C1(03/17)

1

START-UP

4.Mirrors-checkandreadjust

mirrorsifnecessary.

5.Lights-turnignitionkeytotheON

positionandcheckforwarning

lightsandbuzzer.Checkoperation

ofturnsignalsandemergency

lights.

6.Instruments-checkall

instruments.

7.Windshield-checkoperationof

windshieldwipersandwashers.

8.Horn-checkoperationofhorn.

9.Fuel-checkfuel.Isthereenough

fuel?

10.DieselExhaustFluid(DEF)-

checklevel.Isthereenoughuid?

11.Sleeperairconditioningairlter-

checktheconditionofthesleeper

airconditioningairlter.Keep

thesleeperoorareabehind

thepassengerfrontseatclearof

debrisandpethair.Thesleeper

airconditionerdrawsairfromthis

areaandexcessivedirtorpethair

mayshortentheservicelifeofthe

sleeperairconditioningairlter.

Theaboveitemsshouldbechecked

daily,asaminimum.Theyarein

additionto,notinplaceof,Federal

MotorCarrierSafetyRegulations.

Theseregulationsmaybepurchased

bywritingto:

SuperintendentofDocuments

U.S.GovernmentPrintingOfce

Washington,DC20402

WeeklyOperations

1.Battery-checkbatteryand

terminals.

2.WheelCapNuts-aretheyall

inplaceandtorquedproperly-

tightenifnecessary.SeeWheel

CapNutT orqueonpage5-149.

3.OtherControlsandWiring-check

forconditionandadjustment.

4.SteeringComponents-check

pitmanarm,draglink,andpower

steeringhoses,etc.,forloose,

broken,ormissingparts.

5.HVACFreshAirFilter-checkfor

conditionandcleanliness.

6.OtherEngineCompartment

Checks

a.Checkconditionandfastening

ofenginebelt,hoses,clamps,

andradiator.

(03/17)Y53-6060-1C11-35

1

START-UP

b.Checktheaircleaner,mufer,

andexhaustpipes.Arethey

tightandsecure?

c.Automatictransmissionuid

(whenapplicable)-Check

level,aftertheenginehas

warmeduptooperating

temperature.

1-36Y53-6060-1C1(03/17)

1

EMERGENCY

WHATTODOIF...

YouNeedRoadsideAssistance..........2-3

LowAirAlarmTurnsOn.............2-3

StopEngineLampTurnsOn...........2-4

EngineOilPressureLampTurnsOn........2-4

EngineisOverheating..............2-5

FuseorRelayBlows..............2-6

JUMPSTARTINGVEHICLES

Introduction..................2-8

VEHICLERECOVERYANDSPRINGBRAKES

VehicleRecoveryGuidelines..........2-12

ReturningVehicletoService..........2-20

SpringBrakes—ManualRelease........2-20

Sand,Mud,SnowandIce...........2-22

TowingtheVehicle..............2-23

(03/17)Y53-6060-1C12-1

2

WHATTODOIF...

WHATTODOIF...

YouNeedRoadside

Assistance

Calltoll-FREE1-800-4-PETERBILT

(1-800-473-8372)totalktosomeone

atthePACCARCustomerCenter.

•Open24-7-365daysayear

•Theycanhelpyougetroadside

assistance.

•Theyhaveacustommapping

systemwhichlocatesPeterbilt

dealersandIndependentService

Providers(ISPs)nearyouandlists

typesofservicesoffered,hoursof

operationandcontactinformation.

•Theycanassistwithjumpand

pullstarts,tires,trailers,nesand

permits,chains,towing,hazardous

clean-up,outoffuel(roadside),

mechanicalrepairsandpreventive

maintenanceservices.

•Theyhavebilingualagentsand

accesstoatranslationservice

toensurequalityassistance

forcustomerswhospeakany

language.

•Theycan’tansweryourwarranty

questionsbutcangetyouin

contactwithaPeterbiltdealerwho

can.

•ThePACCARCustomerCenter

serviceisFREEevenifyoudon’t

driveaPeterbilt.

LowAirAlarmTurnsOn

1.Slowdowncarefully.

2.Moveasafedistanceofftheroad

andstop.

3.Placethetransmissionin

neutral(parkwithautomatic

transmissions,ifequipped)and

settheparkingbrake.(Refer

toParkingBrakeValveon

page4-43andOperatingthe

Transmissiononpage4-22,for

transmissionshiftingandparking

brakeinformation.)

4.TurnOFFtheengine.

5.TurnONtheemergencyasher

anduseotherwarningdevicesto

alertothermotorists.

(03/17)Y53-6060-1C12-3

2

WHATTODOIF...

WARNING!

Iftheairpressurefallsbelow60

psi(414kPa)thespringbrakes

maystopthevehicleabruptly,which

couldcauseanaccidentresulting

indeathorpersonalinjury.Ob-

servetheredwarninglampsonthe

gauges.Ifonecomeson,donot

continuetodrivethevehicleuntilit

hasbeenproperlyrepairedorser-

viced.

Ifthelightandalarmdonotturnoffat

startup,donottrytodrivethevehicle

untiltheproblemisfoundandxed.

(RefertoUsingtheBrakeSystemon

page4-24,formorebrakeinformation.)

StopEngineLampTurnsOn

StopEngineLamp-If

theStopEnginewarning

lampilluminates,itmeans

youhaveaseriousengine

systemproblem.

WARNING!

Thisshouldbeconsideredanemer-

gency.Youshouldstopthevehicle

assafelyaspossibleandturnOFF

theignition.Thevehiclemustbe

servicedandtheproblemcorrected

beforedrivingagain.Failuretodo

somaycausesevereengineorDPF

damage,orcauseanaccidentwhich

mayresultindeathorpersonalin-

jury.

EngineOilPressureLamp

TurnsOn

EngineOilPressureLamp

-Iftheoilpressuresuddenly

drops,ortheaudiblealarm

andengineoilpressure

warninglightcomeonwhile

driving,dothefollowing:

1.Slowdowncarefully.

2.Moveasafedistanceofftheroad

andstop.

3.Placethetransmissioninpark

andsettheparkingbrake.

(SeeParkingBrakeValveon

page4-43andOperatingthe

Transmissiononpage4-22,for

transmissionshiftingandparking

brakeinformation.)

4.TurnOFFtheengine.

5.TurnONtheemergencyasher

anduseotherwarningdevicesto

alertothermotorists.

2-4Y53-6060-1C1(03/17)

2

WHATTODOIF...

6.Waitafewminutestoallowoilto

drainintotheengineoilpan,and

thenchecktheoillevel.(SeeOil

LevelCheckonpage5-100,for

detailsoncheckingoillevel.)

7.Addoilifnecessary.Iftheproblem

persists,contactanauthorized

dealerassoonaspossible.

CAUTION

Continuingtooperateyourvehicle

withinsufcientoilpressuremay

causesevereenginedamageor

causeanaccidentwhichmayresult

inequipmentorpropertydamage.

Itisimportanttomaintainoilpressure

withinacceptablelimits.Ifoilpressure

dropsbelowtheminimumpsi(kPa)a

RedWarningLampontheoilpressure

gaugewillilluminateandtheStop

EngineLampwillcomeON.

EngineisOverheating

Thecoolingsystemmayoverheatif

thecoolantlevelisbelownormalorif

thereissuddenlossofcoolant,such

asasplithose.Thesystemmayalso

temporarilyoverheatduringsevere

operatingconditionssuchas:

•Climbingalonghillonahotday

•Stoppingafterhigh-speeddriving

Ifeitheroneoftheaboveoccurs,DO

NOTTURNOFFTHEENGINEunless:

a)theLowWaterwarningdevice

indicatesalossofcoolant,b)theRed

Warninglamp(onthegauge)and

CheckEnginelampcomesON,c)the

Buzzersoundsshowinganoverheat

condition,ord)ifyouhaveanyother

reasontosuspecttheenginemaybe

overheating-followthesesteps.

1.Reduceenginespeedand

stop.Whenstopped,placethe

transmissioninNeutralandsetthe

parkingbrake.(SeeParkingBrake

Valveonpage4-43andPutting

theVehicleinMotiononpage

4-19,fortransmissionshiftingand

parkingbrakeinformation.)Keep

theenginerunning.

2.ChecktoensuretheOilPressure

Gaugereadsnormal.

3.Makesuretheenginefanis

turningbyswitchingtheEngine

FanSwitchfromAUTOtoMAN

(Manual).

4.Increasetheenginespeedto

aboutone-halfoffulloperating

speed,or1,100to1,200rpm,

maximum.

5.Returntheenginespeedtonormal

idleafter2or3minutes.

6.Monitortheenginetemperature.

Afterthetemperaturereturnsto

normal,allowtheenginetoidle

3to5minutesbeforeshuttingit

(03/17)Y53-6060-1C12-5

2

WHATTODOIF...

off.Thisallowstheenginetocool

graduallyanduniformly.

7.Ifoverheatingcamefrom

severeoperatingconditions,the

temperatureshouldhavecooled

bythistime.Ifithasnot,stop

theengineandletitcoolbefore

checkingtoseeifthecoolantis

low.

Forfurtherinformationonengine

temperatureandoperatingengines

properly,seetheEngineOperation

andMaintenanceManualandStarting

&OperatingtheVehicleonpage4-5.

Checkthecoolantlevelaftereach

tripwhentheenginehascooled.

Thecoolantlevelshouldbevisible

withinthesurgetank—addcoolantif

necessary.SeeT oppingOffinEngine

CoolingSystemonpage5-80,for

instructionsoncheckingandllingthe

coolantexpansiontank.

WARNING!

Toreducethechanceofdeath,per-

sonalinjuryand/orvehicledamage

fromoverheatedengines,whichcan

resultinare,neverleavetheen-

gineidlingwithoutanalertdriver

present.Iftheengineshouldover-

heat,asindicatedbytheengine

coolanttemperaturelight,immedi-

ateactionisrequiredtocorrectthe

condition.Continuedunattended

operationoftheengine,evenfor

ashorttime,mayresultinserious

enginedamageorare.

WARNING!

Donotremovetheradiatorllcap

whiletheengineishot.Scalding

steamanduidunderpressuremay

escape.Youcouldbebadlyburned.

Failuretocomplymayresultindeath

orpersonalinjury.

FuseorRelayBlows

Fusesarelocatedbehindthedrivers

sidekickpanel,belowtheignition

switch,andaccessiblebyadoorpanel.

SeeFusePanelonpage5-88.

WARNING!

Donotreplaceafusewithafuseofa

higherrating.Doingsomaydamage

theelectricalsystemandcausea

re.Failuretocomplymayresultin

death,personalinjury,equipmentor

propertydamage.

CAUTION

Beforereplacingafuse,turnOFFall

lightsandaccessoriesandremove

theignitionkeytoavoiddamaging

theelectricalsystem.

2-6Y53-6060-1C1(03/17)

2

WHATTODOIF...

CAUTION

Neverpatchfuseswithtinfoilor

wire.Thismaycauseseriousdam-

ageelsewhereintheelectricalcir-

cuit,anditmaycauseare.

CAUTION

Ifacircuitkeepsblowingfuses,have

theelectricalsysteminspectedfora

shortcircuitoroverloadbyanau-

thorizeddealerassoonaspossible.

Failuretodosocouldcauseseri-

ousdamagetotheelectricalsystem

and/orvehicle.

FuseInspectionandReplacement

Alltheelectricalcircuitshavefuses

toprotectthemfromashortcircuitor

overload.Ifsomethingelectricalon

yourchassisstopsworking,therst

thingyoushouldcheckforisablown

fuse.

1.TurnOFFalllightsandaccessories

andremovetheignitionkeyto

avoiddamagingtheelectrical

system.

2.Determinefromthechartonthe

fusepanelwhichfusecontrolsthat

component.

3.Removethatfuseandseeifitis

blown.

1Blown

Ifitisblown,replaceitwithafuseof

thesamerating.

Ifafuseofthesameratingisnot

available,afuseofalowerratingmay

betemporarilysubstituted.Youcan

alsouseafusefromacircuityoucan

dotemporarilywithout(forexamplean

accessorycircuitorradio).

CAUTION

Whenreplacingafailedcircuit

breaker,alwaysuseanapproved

circuitbreakerwithacurrentrat-

ingequaltoorlessthanthecircuit

breakerbeingreplaced.Onlyuse

theapprovedTypeIImodiedre-

setcircuitbreakers.NEVERuse

aTypeI(automaticreset)orType

III(manualreset)circuitbreaker.A

fusewithacurrentratingequaltoor

lessthanthecircuitbreakerbeing

replacedcanalsobeused.

(03/17)Y53-6060-1C12-7

2

JUMPSTARTINGVEHICLES

JUMPSTARTING

VEHICLES

Introduction

Jumpstartingavehicleisnota

recommendedpracticeduetothe

variousbatteryinstallationsand

electricaloptions.

However,ifyourbatteryisdischarged

(dead),youmaybeabletostartit

byusingenergyfromagoodbattery

inanothervehicle.Thisistermed

jumpstarting.Besuretofollowthe

precautionsandinstructionsbelow.

WARNING!

Batteriescontainacidthatcanburn

andgassesthatcanexplode.Ignor-

ingsafetyproceduresmayresultin

death,personalinjury,equipmentor

propertydamage.

WARNING!

Neverjumpstartabatterynearre,

ames,orelectricalsparks.Bat-

teriesgenerateexplosivegases

thatcouldexplode.Keepsparks,

ame,andlightedcigarettesaway

frombatteries.Failuretocomply

mayresultindeath,personalinjury,

equipmentorpropertydamage.

WARNING!

Neverremoveortamperwithbattery

caps.Ignoringthiscouldallowbat-

teryacidtocontacteyes,skin,fab-

rics,orpaintedsurfaces.Failureto

complymayresultindeath,personal

injury,equipmentorpropertydam-

age.

Becarefulthatmetaltools(orany

metalincontactwiththepositive

terminal)donotcontactthepositive

batteryterminalandanyothermetalon

thevehicleatthesametime.Remove

metaljewelryandavoidleaningover

thebattery.

2-8Y53-6060-1C1(03/17)

2

JUMPSTARTINGVEHICLES

ToJumpStartYourVehicle

WARNING!

Whenjumpstartingusingabattery

booster,itisbesttojumpstartwith

anequivalentlypoweredvehicle.

Verifythattheboosterbatteryhas

thesamevoltandCCAspecica-

tionsasthedeadbatterybefore

attemptingtojumpstart.Failure

tocomplymaycauseanexplosion

resultingindeath,personalinjury,

equipmentorpropertydamage.

CAUTION

Applyingahighervoltagebooster

batterymaycauseexpensivedam-

agetosensitiveelectroniccompo-

nents,suchasrelays,Electronic

Controlunitsorelectronicsingen-

eral.Failuretocomplymayresultin

equipmentdamage.

CAUTION

Improperhook-upofjumpercables

ornotfollowingtheseprocedures

candamagethealternatororcause

seriousdamagetobothvehicles.

WARNING!

Heedallwarningsandinstructions

ofthejumpercablemanufacturer.

Failuretocomplymayresultin

death,personalinjury,equipmentor

propertydamage.

Preparingthevehicles:

1.Removeanypersonaljewelry

thatmaycomeincontactwiththe

batteryterminals.

2.Selectajumpercablethatislong

enoughtoattachtobothvehicles

inawaythatensuresneither

vehicletoucheseachother.

3.Positionthetwovehiclestogether,

butdonotallowthemtotouch.

4.TurnOFFalllights,heater,radio,

andanyotheraccessoryonboth

vehicles.

5.Settheparkingbrakes:pullout

theYellowbuttonlocatedonthe

dash.

6.Shiftthetransmissionintopark

positionorneutralformanual

transmissions.(SeeOperating

theTransmissiononpage4-22

andParkingBrakeValveonpage

4-43,fortransmissionshiftingand

parkingbrakeinformation.)

(03/17)Y53-6060-1C12-9

2

JUMPSTARTINGVEHICLES

7.Ifeithervehicleisequippedwith

batterydisconnectsensurethey

areinthe"OFF"positionpriorto

connectingthetwovehicles.

Connectthebatteries:

1.Attachoneendofajumpercable

tothepositive(+)terminalofthe

discharged(dead)battery.This

willhavealargered+orPonthe

batterycase,post,orclamp.

2.Attachtheotherendofthesame

cabletothepositive(+)terminal

ofthegood(booster)battery.

3.Attachtheremainingjumpercable

FIRSTtothenegative(-)terminal

(blackorN)ofthegoodbattery.

4.Attachtheotherendofthe

negativecabletoabaremetalpart

notboltedtotheengineblock.

NOTE

Alwaysconnectpositive(+)to

positive(+)andnegative(-)to

negative(-).

5.Ifeithervehicleisequippedwith

batterydisconnects,ensurethat

theyareinthe"ON"position.

6.Startthevehiclethathasthe

goodbatteryrst.Letitrunfor5

minutes.

7.Startthevehiclethathasthe

discharged(dead)battery.

Iftheenginefailstostart,donot

continuetocrankthestarterbut

contactthenearestauthorizeddealer.

2-10Y53-6060-1C1(03/17)

2

JUMPSTARTINGVEHICLES

Removejumpercables:

WARNING!

Whendisconnectingjumpercables,

makesuretheydonotgetcaughtin

anymovingpartsintheenginecom-

partment.Failuretocomplymayre-

sultindeath,personalinjury,equip-

mentorpropertydamage.

Reversetheaboveprocedureexactly

whenremovingthejumpercables.

Withenginerunning,disconnect

jumpercablesfrombothvehiclesin

theexactreverseorder,makingsure

torstremovethenegativecablefrom

thevehiclewiththedischargedbattery.

(03/17)Y53-6060-1C12-11

2

VEHICLERECOVERYANDSPRINGBRAKES

VEHICLERECOVERY

ANDSPRINGBRAKES

VehicleRecoveryGuidelines

Yourvehicleisequippedwith

removableRecoveryHitches,

designedforshortdistancerecovery

purposesonly.Useonlytheprovided

hitches,accordingthefollowing

instructions.Whenusingthis

connection,donottransportyour

vehicleoverlongdistances.(Ifyour

vehicledoesnothavetheproper

hitches,contactyourdealer.)

Alllubricatingandclutchapplication

oilpressureisprovidedbyan

engine-drivenpump,whichwillnot

workwhentheengineisstopped.

Youcouldseriouslydamageyour

vehiclebytowingitwiththedriveline

connectedandthedrivewheelson

theground.Worse,whenvehiclesare

towed,eitherbywreckerorpiggyback,

thelubricantinthetopfrontofthe

driveaxlewilldraintotherear.This

willleavethetopcomponentsdry.The

resultingfrictionmaydamagethem.

Alwaysremovethemaindriveaxle

shaftsbeforetowingyourvehicle.

CAUTION

Removethedriveaxleshaftsorlift

thedrivingwheelsoffthegroundbe-

foretowingthevehicle.T owingthe

vehiclewitheitherthewheelsonthe

groundortheaxleshaftsintheaxles

willcausedamagetotheaxlegears.

CAUTION

IfyourvehiclehasaMeritoraxle

withadriver-controlledmaindiffer-

entiallock,installthecagingboltbe-

foreremovingtheaxlesfortowing,

seeDriverControlledMainDifferen-

tialLockonpage2-16.Installing

thecagingboltpreventsdamageby

lockinginternalaxlecomponentsin

position.

CAUTION

ConnectonlytotheRecovery

Hitches,seeVehicleRecovery

Guidelinesonpage2-12.Connec-

tionstootherstructuralpartscould

damagethevehicle.Donotattach

tobumpersorbrackets.Useonly

equipmentdesignedforthispur-

pose.Failuretocomplymayresult

inequipmentdamage.

2-12Y53-6060-1C1(03/17)

2

VEHICLERECOVERYANDSPRINGBRAKES

1RecoveryHitchSockets

RecoveryProcedure

1.Reviewandunderstandallthe

cautionsandwarningsofthis

section,seeVehicleRecovery

Guidelinesonpage2-12.

2.Installtherecoveryhitches,see

RecoveryHitchInstallationon

page2-15.

3.Disconnectthedriveaxleshafts

andcovertheopenhubs.This

isnecessarybecauseifthe

transmissionisdrivenbythe

driveshaft(rearwheelsonthe

ground),nolubricantwillreach

thegearsandbearings,causing

damagetothetransmission.

4.Installtherecoveryriggingusinga

safetychainsystem,seeRecovery

Riggingonpage2-19.

5.Makesuretherecoveredvehicle's

parkingbrakesarereleased.

6.Ifyoudesiretousetherecovered

vehicle’sbrakes,ensurethat

thevehicle’sairsystemis

connectedtothatoftherecovery

vehicle.Ensurethatanyairline

thathasbeenremovedfroma

driver-controlledmaindifferential

lockisrmlycappedtoprevent

lossofairpressurefromthe

recoveryvehicleifitissupplying

airpressure.

Ifyoudon’tdesiretousethe

recoveredvehicle’sbrakes,

ensurethatyoucagethespring

brakesbeforeattemptingtomove

thevehicle,seeDriverControlled

MainDifferentialLockonpage

2-16.

(03/17)Y53-6060-1C12-13

2

VEHICLERECOVERYANDSPRINGBRAKES

WARNING!

Beforetowingavehicle,testyourair

brakestoensurethatyouhaveprop-

erlyconnectedandinspectedthere-

coveryvehicle’sbrakesystem.Fail-

uretodosocouldleadtoalossof

vehiclecontrolwhichmayresultinan

accidentinvolvingdeathorpersonal

injury.

7.Followstate/provincialandlocal

lawsthatapplytovehiclesintow.

8.Donottowvehiclesatspeedsin

excessof55mph(90km/h).

Foradditionalinformationconcerning

heavydutytruckrecovery,refertothe

followingT echnology&Maintenance

Council(TMC)literature.

•RecommendedPractice#602–A

—"FrontT owingDevicesFor

TrucksandTractors."

•RecommendedPractice#602–B

—"RecoveryAttachmentPoints

ForTrucks,Tractors,and

CombinationVehicles."

•RecommendedPractice#626

—"HeavyDutyTruckTowing

Procedures."

Copiesofthesecanbeobtainedfrom

thefollowingaddress:

Technology&MaintenanceCouncil

950N.GlebeRoad

(703)838-1763

Arlington,VA22203

Email:[email protected]

http://tmc.truckline.com

RecoveryHitchConnection

Speciallydesignedhitchesare

requiredtorecoveryourvehicle.The

recoveryhitchesattachtotheframe,

seeRecoveryHitchAssemblyonpage

2-15.

Twohitchassemblies,madeupofthe

followingparts,arerecommendedfor

theproperrecoveryofyourvehicle:

seeRecoveryHitchAssemblyonpage

2-15.

WARNING!

Donotusepartsfromothertrucksor

materialsfromothersourcestore-

pairahitchortoreplaceamissing

hitch.Thepartsprovidedforrecov-

eryaremadeofhighstrengthstill

specicallydesignedforvehiclere-

covery.Failuretousethecorrect

factoryequipmentmayresultinan

accidentinvolvingdeathorpersonal

injury.

2-14Y53-6060-1C1(03/17)

2

VEHICLERECOVERYANDSPRINGBRAKES

Ifyourvehicleisnotequippedwith

theproperrecoveryhitchassembly,

contactanauthorizeddealertoobtain

theproperequipment.

RecoveryHitchAssembly

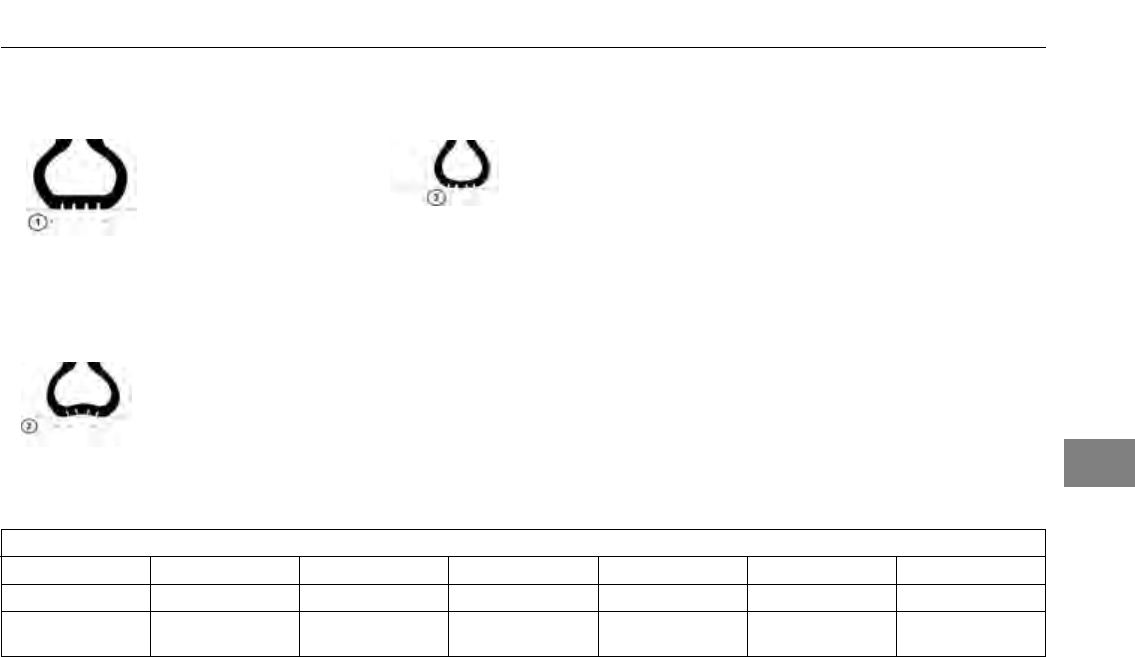

1TowPin

2TowHitch

3SquareHitchSocket

4LockPin

5LockT ab

RecoveryHitchInstallation

Usethefollowingproceduretoinstall

theVehicleRecoveryHitches.See

RecoveryHitchAssemblyillustration

forpartidentication.

1.Checksquaresocketsbehind

lowerbumperforobstructions,

clearifnecessary.

2.Withlockpinsremoved,insert

hitchesthroughbumperandinto

thesquarehitchsocket.

3.Aligntheholeinthetowhitchwith

thesquarehitchsockethole.

4.Insertthelockpinintothesquare

hitchsocketholeandthrough

theholeinthetowhitchuntilthe

locktabiswithinthesquarehitch

socket.

5.Rotatethelockpin90degreesto

securethepininplace.

6.Removethehitchesandstoreall

partsafterrecoveringthevehicle.

DriverControlledMainDifferential

Followthesestepstolocka

driver-controlledmaindifferential.

WARNING!

Anopenairlineontherecovered

vehiclewillcausealeakintheair

systemoftherecoveryvehicleif

bothvehicles’brakesystemsare

connected.Thiscouldcausealoss

ofsystemair,whichcancausethe

servicebrakesnottofunction,re-

sultinginthesuddenapplicationof

thespringbrakescausingwheel

lock-up,lossofcontrol,orovertake

byfollowingvehicles.Youcould

beinanaccidentinvolvingdeath

orpersonalinjury.Ensurethatany

airlinethathasbeenremovedfrom

adriver-controlledmaindifferential

lockisrmlycappedtopreventloss

ofairpressurefromtherecovery

vehicleifitissupplyingairpressure.

(03/17)Y53-6060-1C12-15

2

VEHICLERECOVERYANDSPRINGBRAKES

DriverControlledMainDifferential

Lock

1AirLine(removetoinstall

CagingBolt)

2CagingBolt(instorage

location)

1.Liftdrivingwheelsofftheground

orremovethedrivelineandaxle

shaftsbeforetowingthevehicle.

CAUTION

Failuretoliftthedrivingwheelsoff

thegroundorremovethedriveline

andaxleshaftsbeforetowingtheve-

hiclecouldseriouslydamageyour

vehicle.Alllubricatingandclutchap-

plicationoilpressureisprovidedby

anengine-drivenpump,whichdoes

notworkwhentheengineisstopped.

Whenvehiclesaretowedeitherby

wreckerorpiggyback,lubricantinthe

topfrontofthedriveaxlewilldrainto

therear.Thiswillleavethetopcom-

ponentsdry,resultinginfrictionthat

willseriouslydamagethesecompo-

nents.

2.Coveropenhubswhenremoving

driveaxleshafts.

CAUTION

Water,dirtandothermaterialcan

enteranopenhuboraxle.This

cancontaminatetheaxleuidand

causepossibledamagetocompo-

nents.Ensurethatthehubsarecov-

eredwithplasticwheneveradrive

axleshaftisremoved.

3.Forvehicleswithdriver-controlled

maindifferentiallock,installthe

cagingboltbeforeremovingthe

axleshaftsfortowing.

a.Removetheairlineandrmly

cap.

b.Removethecagingboltfrom

itsstoragehole.

c.Screwthecagingboltinto

theairlinehole.When

fullyengaged,a0.25-0.5

in.(6.35-12.7mm)space

willremainbetweentheair

cylinderandthebolthead.

2-16Y53-6060-1C1(03/17)

2

VEHICLERECOVERYANDSPRINGBRAKES

Thisactionwilllockthe

differentialbypushingapiston

intoa"lock"position.

CAUTION

Failuretoinstallthecagingboltwhen

towingvehicleswithdriver-control

maindifferentiallockcanresultin

damagebyfailingtolockinternal

componentsinposition.

WARNING!

Ensuretherearenoopenairlines

ontherecoveredvehicleifthere-

coveryvehicleandrecoveredvehicle

brakesystemsareconnected.An

openairlineontherecoveredvehi-

clewillcausealeakintheairbrake

systemoftherecoveryvehiclepos-

siblycausingdeath,personalinjury,

equipmentorpropertydamage.

CAUTION

Arecoveredvehiclewillhavenoop-

erationalbrakesystem.Additionally,

therearaxlespringbrakeswillprob-

ablybeapplied.

•Ifyoudesiretousetherecovered

vehicle’sbrakes,ensurethatthe

vehiclesairsystemisconnected

tothatoftherecoveryvehicle.

Alsoensurethatanyairline

thathasbeenremovedfroma

driver-controlledmaindifferential

lockisrmlycappedtoprevent

lossofairpressurefromthe

recoveryvehicle.

•Ifyoudon’tdesiretousethe

recoveredvehicle’sbrakes,

ensurethatyoucagethespring

brakesbeforeattemptingto

movethevehicle.

4.Installrecoveryhitchesand

rigging.

CAUTION

Connectrecoveryriggingonlyto

hitchesintendedforthatpurpose.

Donotattachtobumpersorbrack-

ets.Connectionstootherstructural

partscoulddamagethevehicle.

(03/17)Y53-6060-1C12-17

2

VEHICLERECOVERYANDSPRINGBRAKES

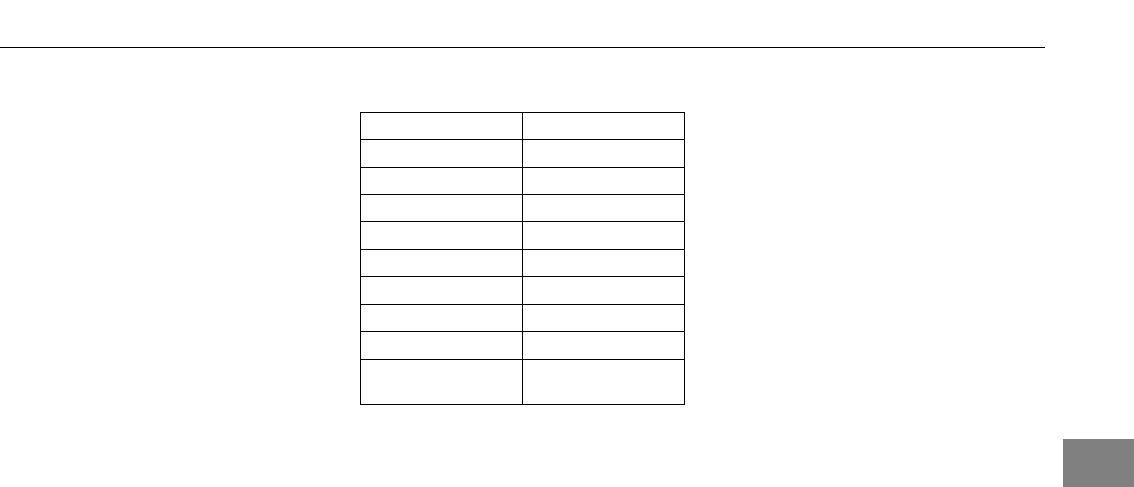

RecoveryHitchCapacities

Themaximumratedloadsforvehicle

recoveryvariesdependingonthe

directionorangleofpull.These

capacitiesarelistedinthetablebelow

andareforthetwohitchesworking

together,simultaneously.

HitchCapacities

DIRECTIONOF

PULL

MAXIMUM

CAPACITY

(Lb)*

DirectlyForward80,000

DirectlyVerticalor

Horizontallytothe

Side

14,600

45ºinanyDirection

20,000

*Bothhitchespulledsimultaneously.

CAUTION

Recoverypullmaximumsassume

thetowriggingevenlydistributesthe

loadbetweenbothrecoveryhitches.

SeeexamplesinRecoveryRigging

onpage2-19fordetails.Serious

damagetothevehiclemayoccurif

riggingisnotconnectedproperly.

CAUTION

Whenrecoveringditchedorbogged

vehicles,staywellbelowMaximum

Capacities.Evenatloadsbelow

maximum,thephysicalstrainofre-

coveringavehiclecoulddamage

axles,suspensions,fthwheels,

etc.

2-18Y53-6060-1C1(03/17)

2

VEHICLERECOVERYANDSPRINGBRAKES

RecoveryRigging

Toconnecttothevehicle,followthe

suggestedriggingmethodsbelow.

•Useadoublechainorcablesetup

thatdistributestheloadequally

tobothhitches.See1or2in

RecoveryRiggingillustration.

•Neverloopasinglechainorcable

throughbothhitches(3).

•Useaspreaderorequalizerbarto

distributetheloadonbothhitches

(1).

•Ifnospreaderbarisavailable,

connectthemaintowchainor

cablenocloserthan6ft.fromthe

vehicle(2).

1.SpreaderBarorEqualizer

2.Minimum6FT .

3.NEVERUSESINGLECHAINORCABLE

Preferred

Acceptable

LOOPEDTHROUGHTOWDEVICES

(03/17)Y53-6060-1C12-19

2

VEHICLERECOVERYANDSPRINGBRAKES

ReturningVehicletoService

Youwillhavetoaddlubricantto

preventdamageafteryourvehiclehas

beentowed.

1.Intothepinioncage,add1pint

(.47liter)oflubricantorintothe

interaxledifferential,add2pints

(.94liter)ofapprovedlubricant.

2.Afteraddingthespeciedtype

andamountoflubricant,drivethe

vehicle.Itshouldbeunloaded.

Drive1to2miles(1.5to3km)

ataspeedlowerthan25mph

(40km/h).Thiswillthoroughly

circulatethelubricantthroughthe

assembly.

SpringBrakes—Manual

Release

Recoveringavehiclerequiresthatyou

releasetheparkingbrakes.Theremay

betimeswhenthereisnotenoughair

pressuretoreleasetheparkingbrakes.

Insuchcases,theparkingbrakes

(orSpringBrakes)canbemanually

released.

WARNING!

Donotdrivevehiclewithmalfunc-

tioningbrakes.Ifoneofthebrake

circuitsshouldbecomeinoperative,

brakingdistanceswillincreasesub-

stantiallyandhandlingcharacteris-

ticswhilebrakingwillbeaffected.

Youcouldlosecontrolofyourvehi-

cleorcauseanaccident.Haveit

towedtothenearestdealerorqual-

iedrepairfacilityforrepair.Failure

tocomplymayresultindeath,per-

sonalinjury,equipmentorproperty

damage.

Thebrakescanbereleasedinthis

mannershouldthepressureintheair

systemnotbeenoughtoreleasethem.

Thismayoccurininstanceswhere

theengine'saircompressorisnot

abletogetthesystemuptooperating

pressure.

WARNING!

Donotdisassembleaspringbrake

chamber.Thesechamberscon-

tainapowerfulspringthatiscom-

pressed.Suddenreleaseofthis

springmayresultindeathorper-

sonalinjury.

2-20Y53-6060-1C1(03/17)

2

VEHICLERECOVERYANDSPRINGBRAKES

WARNING!

Donotoperateavehiclewhenthe

springbrakeshavebeenmanually

released.Drivingavehicleafterits

springbrakesaremanuallyreleased

isextremelydangerous.Thebrakes

maynotfunction.Failuretocomply

mayresultindeath,personalinjury,

equipmentorpropertydamage.

WARNING!

Alwayssecurethevehiclewith

wheelchocks,chains,orother

safemeanstopreventrollingbe-

foremanuallyreleasingthespring

brakes.Releasingthespringbrakes

onanunsecuredvehiclecouldlead

toanaccident.Thevehiclecould

roll,whichmayresultindeath,per-

sonalinjury,equipmentorproperty

damage.

Tomoveavehicleimmobilizedby

thespringbrakesduetolossofair

pressureinthebrakesystem,perform

thefollowingprocedure:

1.Removethe

capfromthespring

chamber.

2.Removethe

releasestud

assemblyfromthe

sidepocket,and

removetherelease

nutandwasherfrom

thereleasestud.

3.Slideoutthe

releasestud.

4.Inserttherelease

studthroughthe

openinginthespring

chamberwherethe

capwasremoved.

Insertitintothe

pressureplate.Turn

thereleasestud1/4

turnclockwiseinthe

pressureplate.This

securesthecross

pinintothecrosspin

areaofthepressure

plateandlocksitinto

themanualrelease

position.

5.Assemblethe

releasestudwasher

andnutonthe

releasestud.

(03/17)Y53-6060-1C12-21

2

VEHICLERECOVERYANDSPRINGBRAKES

6.Withawrench,

turnthereleasestud

assemblynutuntilthe

compressionspring

is90-95percent

caged.Whiledoing

this,checktomake

surethepushrod

(adapterpushrod

orservicepush

rod)isretracting.

Donotover-torque

thereleasestud

assembly.(S-Cam

typemaximum:50

lb-ft,Wedgetype

maximum:30lb-ft).

Thespringbrakeis

nowmechanically

released.

Sand,Mud,SnowandIce

Ifthevehiclegetsstuckinsand,

mud,snow,orice:

•Movethegearshiftleveror

selectorfromFirsttoReverse.

•Applylightpressureonthe

acceleratorpedalwhilethe

transmissionisingear.

•Removeyourfootfromthe

acceleratorwhileshifting.

•Donotracetheengine.

•Forbesttractionandsafety,avoid

spinningthewheels.

WARNING!

Donotspinthewheelsfasterthan

35mph(55km/h).Spinningatireat

speedometerreadingsfasterthan

35mph(55km/h)canbedangerous.

Tirescanexplodefromspinningtoo

fast.Undersomeconditions,atire

maybespinningataspeedtwice

thatshownonthespeedometer.

Anyresultingtireexplosioncould

causedeathorpersonalinjurytoa

bystanderorpassenger,aswellas

extensivevehicledamage:includ-

ingtire,transmissionand/orrear

axlemalfunction.

Complywiththefollowing

instructionstoavoidtransmission

damage:

•Alwaysstartvehicleinmotionwith

theshiftleverinrstgear.

2-22Y53-6060-1C1(03/17)

2

VEHICLERECOVERYANDSPRINGBRAKES

•Besurethattransmissionisfully

engagedingearbeforereleasing

theclutchpedal(manualonly).

•Donotshiftintoreversewhilethe

vehicleismoving.

•Ifthevehicleneedstobe

recoveredfrombeingstuck,donot

permitthevehicletobetowedfor

longdistanceswithoutremoving

thedriveshaft.

TireChains

Ifyouneedtirechains,installthemon

bothsidesofthedrivingaxle.

CAUTION

Chainsonthetiresofonlyonetan-

demaxlecandamagethedriveline