Leitz Lexicon Edition 7

Sawing

Version 3

Anpassung der Rückenstärke für Druck noch nicht ausgeführt

11/2023

Explanation of abbreviations

A = dimension A

a

e

= cutting thickness (radial)

a

p

= cutting depth (axial)

ABM = dimension

APL = panel raising length

APT = panel raising depth

AL = working length

AM = number of knives

AS = anti sound (low noise design)

b = overhang

B = width

BDD = thickness of shoulder

BEM = note

BEZ = description

BH = tipping height

BO = bore diameter

CNC = Computerized Numerical Control

d = diameter

D = cutting circle diameter

D0 = zero diameter

DA = outside Diameter

DB = diameter of shoulder

DFC = Dust Flow Control (optimised chip clearance)

DGL = number of links

DIK = thickness

DKN = double keyway

DP = polycrystalline diamond

DRI = rotation

FAB = width of rebate

FAT = depth of rebate

FAW = bevel angle

FLD = flange diameter

f

z

= tooth feed

f

z eff

= effective tooth feed

GEW = thread

GL = total length

GS = Plunging edge

H = height

HC = tungsten carbide, coated

HD = wood thickness (thickness of workpiece)

HL = high-alloyed tool steel

HS = high-speed steel (HSS)

HW = tungsten carbide (TCT)

ID = ident number

IV = insulation glazing

KBZ = abbreviation

KLH = clamping height

KM = edge breaker

KN = single keyway

KNL = combination pinhole consists of

2/7/42 2/9/46,35 2/10/60

L = length

l = clamping length

LD = left hand twist

LEN = Leitz standard profiles

LH = left hand rotation

M = metric thread

MBM = minimum order quantity

MC = multi-purpose steel, coated

MD = thickness of knife

min

-1

= revolutions per minute (RPM)

MK = morse taper

m min

-1

= metres per minute

m s

-1

= metres per second

n = RPM

n

max

. = maximum permissible RPM

NAL = position of hub

ND = thickness of hub

NH = zero height

NL = cutting length

NLA = pinhole dimensions

NT = grooving depth

P = profile

POS = cutter position

PT = profile depth

PG = profile group

QAL = cutting material quality

R = radius

RD = right hand twist

RH = right hand rotation

RP = radius of cutter

S

SB

SET

SLB

SLL

SLT

SP

ST

STO

SW

= shank dimension

= cutting width

= set

= slotting width

= slotting length

= slotting depth

= tool steel

= Cobalt-basis cast alloys,

e.g. Stellite

TM

= shank tolerance

= cutting angle

TD = diameter of tool body

TDI = thickness of tool

TG = pitch

TK = reference diameter

UT = cutting edges with irregular pitch

V = number of spurs

v

c

= cutting speed

v

f

= feed speed

VE = packing unit

VSB = adjustment range

WSS = workpiece material

Z = number of teeth

ZA = number of fingers

ZF = tooth shape (cutting edge shape)

ZL = finger length

Notes to the Lexicon concerning the diagrams and tables

The statements made in the diagrams and tables relate to specific conditions and represent parameters from tests subjected to defined conditions. Variations

when using tools in individual case due to special application conditions may be possible. Our support team will provide you with detailed information.

1

1. Sawing

1.1 Solid wood cutting along grain 10

1.1.1 Circular sawblades thin kerf 12

1.1.2 Circular sawblades with wiper teeth 14

1.1.3 Circular sawblades without wiper teeth 18

1.2 Solid wood cutting across grain 21

1.2.1 Circular sawblades for optimising saws 22

1.2.2 Circular sawblades WZ with neg. cutting angle 23

1.2.3 Circular sawblades for joinery machines 25

1.3 Sizing 26

1.3.1 Sizing sawblades WZ 27

1.3.2 Sizing sawblades Katana 30

1.3.3 Sizing sawblades WhisperCut 31

1.3.4 Sizing sawblades HZ/DZ 32

1.3.5 Sizing sawblades FZ/TR 34

1.3.6 Sizing sawblades FZ 35

1.3.7 Scoring sawblades for table and panel saws 38

1.4 Panel sizing 40

1.4.1 Panel sizing sawblades WZ 41

1.4.2 Panel sizing sawblades FZ/TR 42

1.4.3 Panel sizing sawblades TR/TR 44

1.4.4 Scoring sawblades for panel saws KON 48

1.4.5 Scoring sawblades - softforming / postforming 51

1.4.6 Overview scoring and main sawblades 52

1.4.7 Circular sawblades for floor production 56

1.6 Circular sawblades for CNC 68

1.6.1 Trimming and sizing sawblades 69

1.6.2 Grooving sawblades 72

1.7 Portable saws and table-top machines 73

1.7.1 Circular sawblades WZ 74

1.7.2 Circular sawblades FZ/TR 78

1.7.3 Circular sawblades for metals - DryCut 80

1.7.4 Circular sawblades for plastics and NF-metals 81

1.7.5 Circular sawblades for saw benches 82

1.7.6 Circular sawblades for fibre cement boards 83

1.7.7 Accessories reducing rings 84

Troubleshooting 85

Signs of wear 87

Enquiry/order form special tools – sawing 89

Alphabetical product index 91

ID index 93

1.5 Cutting non-ferrous metals and plastics 57

1.5.1 Cross and mitre cut sawblades for profiles 58

1.5.2 Circular sawblades for solid panels and blocks 64

2

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

80

2,8 -

3,8

20 20 HW FZ 10 165401 38

80

3,3 20 18 DP HZ/WZ 10 190700 31

100 2,4 12 30 HW WZ 10 166109 75

100 2,4 22 30 HW WZ 10 166110 75

100 2,8 -

3,8

20 20 HW FZ 10 165402 38

100 2,8 -

3,8

22 20 HW FZ 10 165403 38

100 3,2 20 20 HW KON/FZ 5 165625 49

100 3,2 22 20 HW KON/FZ 5 165626 49

100 3,5 20 35 HW WZ/WZ/FZ 15 166014 72

100 3,5 30 35 HW WZ/WZ/FZ 15 166000 72

100 4,0 20 12 DP FZ 10 192303 72

100 4,0 20 35 HW WZ/WZ/FZ 15 166015 72

100 4,0 30 35 HW WZ/WZ/FZ 15 166008 72

100 5,0 20 35 HW WZ/WZ/FZ 15 166016 72

100 5,0 30 35 HW WZ/WZ/FZ 15 166001 72

100 8,5 20 35 HW WZ/WZ/FZ 15 166013 72

100 8,5 30 35 HW WZ/WZ/FZ 15 166017 72

120 2,4 20 24 HW WZ 15 166111 75

120 2,8 -

3,8

20 24 HW FZ 10 165404 38

120 2,8 -

3,8

20 24 DP FZ 10 190731 39

120 2,8 -

3,6

22 24 HW FZ 10 165405 38

120 2,8 -

3,8

22 24 HW FZ 10 165406 38

120 2,8 -

3,8

22 24 DP FZ 10 190694 39

120 2,8 -

3,8

50 24 HW FZ 10 165412 38

120 2,8 -

3,8

50 24 DP FZ 10 190704 39

120 3,2 20 24 HW KON/FZ 5 165627 49

120 3,3 20 18 DP HZ/WZ 10 190701 31

120 3,3 22 18 DP HZ/WZ 10 190702 31

120 3,5 20 35 HW WZ/WZ/FZ 15 166002 72

120 3,5 35 35 HW WZ/WZ/FZ 15 166004 72

120 4,0 20 35 HW WZ/WZ/FZ 15 166009 72

120 4,0 35 35 HW WZ/WZ/FZ 15 166010 72

120 5,0 20 35 HW WZ/WZ/FZ 15 166003 72

120 5,0 35 35 HW WZ/WZ/FZ 15 166005 72

125 2,4 20 36 HW WZ 10 166113 75

125 2,4 20 24 HW WZ 15 166112 75

125 2,8 -

3,8

20 24 HW FZ 10 165407 38

125 2,8 -

3,8

20 24 DP FZ 10 190695 39

125 3,1 20 20 DP KON/FZ 10 190564 50

125 3,2 20 24 HW KON/WZ 5 165550 48

125 3,2 22 24 HW KON/WZ 5 165551 48

125 3,3

20 18 DP HZ/WZ 10 190703 31

125 3,5 30 35 HW WZ/WZ/FZ 15 166006 72

125 4,0 30 35 HW WZ/WZ/FZ 15 166011 72

125 4,4 20 24 HW KON/FZ 5 165628 49

125 4,4 45 24 HW KON/WZ 5 165553 48

125 4,4 45 24 HW KON/FZ 5 165629 49

125 5,0 30 35 HW WZ/WZ/FZ 15 166007 72

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

140 1,8 20 35 HW WZ/WZ/

WZ/FZ

10 166623 74

140 2,4 20 24 HW WZ 15 166114 75

140 2,8 -

3,8

36 24 HW WZ 10 165408 38

150 2,8 20 48 HW WZ 10 166115 75

150 3,2 30 48 HW WZ 10 163100 27

150 3,2 30 42 HW FZ 10 165375 36

150 4,3 30 24 DP KON/FZ 10 190565 50, 53

150 4,4 20 24 HW KON/WZ 5 165554 48

150 4,4 30 36 HW KON/WZ 5 165555 48, 53

150 4,4 30 24 HW KON/WZ 5 165556 48, 53

150 4,4 45 24 HW KON/WZ 5 165557 48, 53

150 4,4 45 28 HW KON/WZ 5 165558 48, 53

160 1,6 20 24 HW WZ 25 166100 75

160 1,8 16 48 HW WZ 10 060574 29

160 1,8 20 32 HW WZ 5 166102 75

160 1,8 20 48 HW FZ/TR 5 166311 78

160 1,8 20 42 HW WZ/WZ/

WZ/FZ

10 166620 74

160 1,8 20 18 HW WZ 25 166101 75

160 2,0 20 48 HW FZFA/FZFA 0 163529 80

160 2,2 20 48 HW FZFA/FZFA 5 161008 81

160 2,2 20 4 DP FZ 5 190752 83

160 2,5 20 56 HW FZ/TR -5 166350 79

160 2,5 20 30 DP HZFA/

WZFA

10 190751 71

160 2,5 20 24 HW WZ 15 166117 75

160 2,5 20 48 HW WZ 15 166118 75

160 2,5 20 12 HW WZ 20 166116 75

160 2,6 20 48 HW FZ/TR 5 166300 78

160 3,2 20 32 HW KON/WZ 5 165559 48

160 3,2 20 4 DP P 5 190302 83

160 4,3 55 30 DP KON/FZ 10 190566 50, 52

160 4,4 30 36 HW KON/WZ 5 165560 48

160 4,4 45 36 HW KON/WZ 5 165561 48

160 4,4 55 36 HW KON/WZ 5 165562 48, 52

165 1,8 20 48 HW FZ/TR 5 166312 78

165 1,8 20 42 HW WZ/WZ/

WZ/FZ

10 166621 74

165 1,8 20 18 HW WZ 15 166159 75

165 2,0 20 48 HW FZFA/FZFA 0 163530 80

165 2,2 20 56 HW FZ/TR -5 166351 79

165 2,2 20 48 HW FZFA/FZFA 5 161009 81

165 2,2 20 4 DP FZ 5 190753 83

165 2,2 20 48 HW WZ 10 166104 75

165 2,2 20 24 HW WZ 15 166119 75

165 2,4

20 12 HW WZ 15 166103 75

170 2,5 30 48 HW WZ 10 166120 75

180 1,3 60 32 HW FZ 20 057418 12

180 1,5 60 21 HW FZ 20 057443 12

180 1,6 16 56 HW WZ 10 060591 29

180 1,8 60 32 HW FZ 20 057412 12

180 1,8 60 21 HW FZ 20 057444 12

180 2,2 30 18 HW FZ 15 165300 18

180 2,4 16 58 HW WZ 10 059665 29

180 2,4 30 30 HW WZ 10 163101 27

180 2,4 30 24 HW FZ 15 165301 18

180 2,5 20 48 HW WZ 10 166122 75

180 2,5 20 24 HW WZ 15 166121 75

180 2,5 30 48 HW WZ 10 166105 75

1. Sawing Quick search

3

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

180 2,5 30 35 DP HZFA/

WZFA

10 190713 71

180 2,5 30 24 HW WZ 15 166123 75

180 2,5 40 35 DP HZFA/

WZFA

10 190714 71

180 3,0 -

3,8

22 36 HW WZ 10 165410 38

180 3,0 30 60 HW WZ/WZ/FZ 10 161250 70

180 3,0 30 60 HW WZ/WZ/FZ 10 161267 70

180 3,0 30 24 HW WZ 10 163102 27

180 3,0 40 60 HW WZ/WZ/FZ 10 161251 70

180 3,0 -

3,8

50 36 HW FZ 10 165413 38

180 3,2 16 42 HW FZ/TR 5 166301 78

180 3,2 20 42 HW FZ/TR -5 166352 79

180 3,2 20 36 HW KON/WZ 5 165563 48

180 3,2 30 58 HW WZ 10 163103 27

180 3,2 30 48 HW FZ 10 165378 36

180 3,2 30 36 DP DZ/TR 10 190747 67

180 3,2 65 48 HW FZ 10 165379 36

180 3,2 65 48 HW FZ 10 165380 36

180 3,2 65 58 HW FZ 10 165381 36

180 3,2 65 58 HW FZ 10 165382 36

180 3,2 65 24 DP FZ 10 190660 37

180 3,2 65 24 DP FZ 10 190661 37

180 3,2 65 36 DP FZ 10 190662 37

180 3,2 65 36 DP FZ 10 190663 37

180 3,2 65 48 DP FZ 10 190664 37

180 3,2 65 48 DP FZ 10 190665 37

180 3,5 30 30 HW WZ 10 163104 27

180 3,8 60 24 HW WZ 20 165255 13

180 4,3 30 30 DP KON/FZ 10 190567 50, 52,

54-55

180 4,3 45 30 DP KON/FZ 10 190568 50,

52-53

180 4,4 20 36 HW KON/WZ 5 165564 48

180 4,4 20 28 HW KON/FZ 5 165630 49

180 4,4 30 30 HW KON/FZ 5 165632 49, 52,

54-55

180 4,4 45 30 HW KON/WZ 5 165565 48,

52-53

180 4,4 45 36 HW KON/WZ 5 165566 48,

52-53

180 4,4 45 36 HW KON/FZ 5 165633 49,

52-53

180 4,5 50 36 HW KON/WZ 5 165567 48

180 4,55 30 36 HW WZFA 10 165681 51

180 4,7 45 30 DP KON/FZ 10 190569 50, 53

180 4,8 45 36 HW KON/FZ 5 165634 49, 53

180 5,8 20 36 HW KON/FZ 5 165631 49

184 1,8 20 42 HW WZ/WZ/

WZ/FZ

10 166624 74

184 2,5 20

24 HW WZ 15 166124 75

184 3,2

20 4 DP P 5 190696 83

190 1,8 20 72 HW FZFA/FZFA -5 060278 62

190 1,8 30 54 HW FZ/TR 5 166313 78

190 1,8 30 42 HW WZ/WZ/

WZ/FZ

10 166622 74

190 1,8 30 24 HW WZ 15 166160 75

190 2,0 30 54 HW FZFA/FZFA 0 163531 80

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

190 2,2 30 4 DP FZ 5 190754 83

190 2,4 20 58 HW FZFA/FZFA 5 161010 81

190 2,5 30 24 HW WZ 20 166128 75

190 2,8 16 48 HW WZ 10 166126 75

190 2,8 16 24 HW WZ 15 166125 75

190 2,8 30 68 HW FZ/TR -5 166354 79

190 2,8 30 54 HW FZ/TR 5 166302 78

190 2,8 30 48 HW WZ 10 166129 75

190 2,8 30 16 HW WZ 20 166127 75

190 3,2 20 4 DP P 5 190303 83

190 3,2 30 4 DP P 5 190745 83

200 1,5 60 36 HW FZ 20 057421 12

200 1,5 60 21 HW FZ 20 057445 12

200 1,8 20 80 HW FZFA/FZFA -5 060274 62

200 1,8 60 21 HW FZ 20 057446 12

200 2,0 16 64 HW WZ 10 059666 29

200 2,0 30 24 HW FZ 20 163575 16

200 2,4 30 36 HW WZ 10 163105 27

200 2,4 30 60 HW WZ 10 163106 27

200 2,4 30 18 HW FZ 15 165302 18

200 2,4 30 24 HW FZ 15 165303 18

200 2,4 40 24 HW FZ 20 163550 17

200 2,5 30 40 DP HZFA/

WZFA

10 190715 71

200 2,5 30 40 DP HZFA/

WZFA

10 190716 71

200 2,8 20 84 HW FZ/TR 5 166303 78

200 3,0 30 65 HW WZ/WZ/FZ 10 161253 70

200 3,0 30 65 HW WZ/WZ/FZ 10 161254 70

200 3,0 30 24 HW WZ 10 163107 27

200 3,0 30 48 HW WZ 10 163108 27

200 3,0 30 60 HW WZ 10 163109 27

200 3,0 30 34 HW WZ 10 166130 75

200 3,0 30 48 HW WZ 10 166131 75

200 3,2 30 60 HW FZ/TR -5 166356 79

200 3,2 30 60 HW KON/WZ 5 165571 48

200 3,2 30 48 HW FZ/TR 5 166304 78

200 3,2 30 54 HW FZ 10 165383 36

200 3,2 30 18 HW FZ 25 165108 19

200 3,8 60 24 HW WZ 20 165259 13

200 4,3 20 30 DP KON/FZ 10 190570 50, 54

200 4,3 30 30 DP KON/FZ 10 190571 50

200 4,3 45 30 DP KON/FZ 10 190572 50, 53

200 4,3 65 30 DP KON/FZ 10 190615 50, 55

200 4,4 20

36 HW KON/WZ

5 165569 48, 54

200 4,4 30 36 HW KON/WZ 5 165572 48

200 4,4 45 36 HW KON/WZ 5 165574 48, 53

200 4,4 65 36 HW KON/WZ 5 165576 48, 55

200 4,4 80 36 HW KON/FZ 5 165637 49, 52

200 4,7 45 30 DP KON/FZ 10 190573 50

200 4,7 65 30 DP KON/FZ 10 190574 50, 55

200 4,8 20 36 HW KON/WZ 5 165573 48, 54

200 4,8 45 36 HW KON/FZ 5 165636 49

200 4,8 65 36 HW KON/WZ 5 165577 48, 55

200 5,0 30 60 HW WZ/WZ/FZ 15 166012 72

200 5,0 30 24 HW FZ 20 165250 13

200 5,8 45 36 HW KON/WZ 5 165575 48, 52

200 6,2 20 36 HW KON/WZ 5 165570 48

200 6,8 20 36 HW KON/FZ 5 165635 49

210 2,0 30 60 HW FZFA/FZFA 0 163532 80

1. Sawing Quick search

4

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

210 2,2 100 36 DP FZ 3 190676 56

210 2,2 115 36 DP FZ 3 190677 56

210 2,4 30 64 HW FZ/TR -5 166357 79

210 2,4 30 68 HW FZFA/FZFA 5 161011 81

210 2,4 30 64 HW WZ 10 166135 75

210 2,4 30 24 HW WZ 15 166133 75

210 2,4 30 42 HW WZ 20 166134 75

210 2,8 30 60 HW WZ -5 166252 77

210 2,8 30 60 HW FZ/TR -5 166358 79

210 3,2 30 18 HW FZ 20 165109 19

215 4,4 50 42 HW KON/WZ 5 165578 48

216 1,8 30 48 HW WZ -5 166260 77

216 2,2 30 64 HW FZ/TR -5 166366 79

216 3,0 30 24 HW WZ -5 166253 77

216 3,0 30 48 HW WZ -5 166254 77

216 3,0 30 64 HW WZ -5 166255 77

216 3,0 30 64 HW FZ/TR -5 166359 79

220 1,2 60 27 HW FZ 20 057475 12

220 1,2 65 24 HW FZ 20 057474 12

220 1,3 60 24 HW FZ 25 057476 12

220 1,3 60 32 HW FZ 25 057478 12

220 1,3 65 24 HW FZ 25 057477 12

220 1,3 65 32 HW FZ 25 057479 12

220 1,4 60 32 HW FZ 20 057464 12

220 1,4 60 24 HW FZ 25 057480 12

220 1,4 65 32 HW FZ 20 057465 12

220 1,4 65 24 HW FZ 25 057481 12

220 2,4 40 24 HW FZ 20 163551 17

220 2,5 30 45 DP HZFA/

WZFA

10 190717 71

220 2,5 40 45 DP HZFA/

WZFA

10 190718 71

220 3,0 30 70 HW WZ/WZ/FZ 10 161255 70

220 3,0 40 70 HW WZ/WZ/FZ 10 161256 70

220 3,1 45 48 DP KON/FZ 10 190744 50

220 3,2 30 42 HW HZ/DZ -5 163075 33

220 3,2 30 72 HW FZ/TR -5 166360 79

220 3,2 30 64 HW FZ/TR 10 163000 34

220 3,2 30 42 HW HZ/DZ 10 163050 33

220 3,2 30 36 HW WZ 10 163110 27

220 3,2 30 60 HW WZ 10 163111 27

220 3,2 30 60 HW WZ 10 166107 75

220 3,2 30 34 HW WZ 15 166136 75

220 3,2 45 60 HW KON/FZ 5 165638 49

220 3,35 30

48 HW FZ/TR 10 165676 51

220 3,8

60 24 HW WZ 20 165260 13

220 3,8 60 24 HW WZ 20 165262 13

220 3,8 65 24 HW WZ 20 165261 13

220 5,0 30 24 HW FZ 20 165251 13

220 6,5 20 36 HW KON/WZ 5 165579 48, 54

225 1,5 60 25 HW FZ 20 057447 12

225 1,6 60 32 HW FZ 25 057482 12

225 1,8 60 25 HW FZ 20 057448 12

225 2,0 40 40 HW FZ 20 163600 12

225 2,0 60 25 HW FZ 20 057449 12

225 2,2 30 64 HW FZFA/FZFA 0 163533 80

225 2,4 30 24 HW FZ 15 165304 18

225 2,6 30 68 HW FZ/TR -5 166361 79

225 2,6 30 48 HW WZ 10 166138 75

225 2,6 30 32 HW WZ 20 166137 75

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

225 2,8 30 24 HW FZ 15 165305 18

225 3,2 30 6 DP P 5 190304 83

225 3,8 60 24 HW WZ 20 165263 13

225 5,0 30 24 HW FZ 20 165252 13

225 5,0 60 40 HW FZ 20 165256 13

230 2,5 30 48 HW WZ 15 166108 75

230 2,5 30 24 HW WZ 20 166140 75

230 3,2 30 34 HW WZ 15 166141 75

235 2,5 30 24 HW WZ 15 166156 75

235 2,5 30 56 HW WZ 15 166157 75

235 2,5 30 12 HW WZ 15 166158 75

235 3,2 30 24 HW WZ 15 166142 75

235 3,2 30 34 HW WZ 15 166143 75

240 2,5 30 50 DP HZFA/

WZFA

10 190719 71

240 2,5 40 50 DP HZFA/

WZFA

10 190720 71

240 2,8 40 24 HW FZ 15 165306 18

240 3,0 30 75 HW WZ/WZ/FZ 10 161257 70

240 3,0 30 75 HW WZ/WZ/FZ 10 161268 70

240 3,0 30 48 HW WZ 10 166145 75

240 3,0 30 34 HW WZ 15 166144 75

240 3,0 40 75 HW WZ/WZ/FZ 10 161258 70

240 3,0 40 30 HW WZ 15 165337 25

250 1,7 30 80 HW WZ 10 058520 29

250 1,7 60 36 HW FZ 20 057433 12

250 1,7 60 25 HW FZ 20 057450 12

250 2,0 30 100 HW FZFA/FZFA -5 060275 62

250 2,0 60 36 HW FZ 20 057434 12

250 2,0 60 25 HW FZ 20 057451 12

250 2,0 80 36 HW WZ 15 163576 16

250 2,0 100 48 DP FZ 3 190678 56

250 2,0 100 48 DP FZ 3 190679 56

250 2,0 115 48 DP FZ 3 190680 56

250 2,2 100 36 DP FZ 3 190681 56

250 2,2 100 36 DP FZ 3 190682 56

250 2,2 100 48 DP FZ 3 190684 56

250 2,2 100 48 DP FZ 3 190685 56

250 2,2 115 36 DP FZ 3 190683 56

250 2,2 115 48 DP FZ 3 190686 56

250 2,4 30 48 HW WZ -5 166256 77

250 2,4 30 60 HW WZ -5 166257 77

250 2,4 30 40 HW WZ 10 163112 27

250 2,4 30 80 HW WZ 10 163113 27

250 2,4 30

24 HW FZ 20 163558 17

250 2,4

40 24 HW FZ 20 163552 17

250 2,4 60 24 HW FZ 20 163700 17

250 2,4 60 40 HW FZ 20 163701 17

250 2,4 70 24 HW FZ 20 163553 17

250 2,4 80 32 HW WZ 15 163577 16

250 2,4 80 40 HW WZ 15 165309 18

250 2,4 80 24 HW FZ 20 163554 17

250 2,5 30 50 DP HZFA/

WZFA

10 190721 71

250 2,8 30 72 HW FZFA/FZFA 5 161012 81

250 2,8 30 24 HW FZ 15 165307 18

250 2,8 30 60 HW WZ 20 166147 76

250 2,8 30 24 HW WZ 25 166146 76

250 2,8 70 24 HW FZ 15 165308 18

250 3,0 30 80 HW WZ/WZ/FZ 10 161259 70

250 3,2 30 48 HW HZ/DZ -5 163076 33

1. Sawing Quick search

5

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

250 3,2 30 80 HW WZ -5 163225 28

250 3,2 30 80 HW WZ -5 166258 77

250 3,2 30 60 HW FZ/TR -5 166362 79

250 3,2 30 80 HW FZ/TR -5 166363 79

250 3,2 30 60 HW FZ/TR 5 166305 78

250 3,2 30 80 HW FZ/TR 5 166306 78

250 3,2 30 54 HW HZ/DZ 10 161300 32

250 3,2 30 60 HW FZ/TR 10 163002 34

250 3,2 30 80 HW FZ/TR 10 163003 34

250 3,2 30 48 HW HZ/DZ 10 163051 33

250 3,2 30 40 HW WZ 10 163114 27

250 3,2 30 60 HW WZ 10 163115 27

250 3,2 30 80 HW WZ 10 163116 27

250 3,2 30 50 DP HZFA/

WZFA

10 190697 31

250 3,2 30 48 DP DZ/TR 10 190748 67

250 3,2 30 60 HW TR/TR 15 161135 45

250 3,2 30 18 HW FZ 20 165110 19

250 3,2 30 18 HW FZ 20 166050 20

250 3,2 30 24 HW WZ 20 166076 20

250 3,2 32 60 HW FZ/TR 5 166307 78

250 3,2 32 80 HW FZ/TR 5 166308 78

250 3,2 40 80 HW FZ/TR 5 166309 78

250 3,2 70 20 HW WZ 20 165200 15

250 3,2 100 48 HW FZ 10 061434 56

250 3,5 30 18 HW FZ 25 165008 14

250 3,5 80 18 HW FZ 25 165009 14

250 3,8 60 24 HW WZ 20 165264 13

250 4,0 30 18 HW FZ 20 165101 19

250 4,4 30 42 HW KON/FZ 5 165639 49

250 4,4 30 18 HW FZ 25 165000 14

250 4,4 80 18 HW FZ 25 165001 14

250 4,55 30 48 HW FZ/TR 10 165677 51

250 5,0 30 24 HW FZ 20 165253 13

250 5,0 30 36 HW FZ 20 165254 13

250 8,0 80 24 HW FZ 15 165257 13

254 2,2 30 72 HW FZFA/FZFA 0 163534 80

255 2,8 30 60 HW WZ -5 166259 77

255 2,8 30 80 HW WZ/WZ/FZ 10 161200 30

260 2,4 30 68 HW FZ/TR -5 166364 79

260 2,5 30 60 HW WZ -5 166250 77

260 2,5 30 80 HW WZ -5 166251 77

260 3,2 30 60 HW WZ 10 166148 76

270 2,4 60 28

HW FZ 20 163702 17

275 3,2

30 88 HW FZ/TR -5 166365 79

275 3,4 40 72 HW FZ/TR 5 166310 78

280 2,5 30 55 DP HZFA/

WZFA

10 190722 71

280 3,0 30 85 HW WZ/WZ/FZ 10 161260 70

280 3,2 30 60 HW FZ/TR 10 163004 34

280 3,2 30 48 HW WZ 10 166149 76

280 3,2 30 60 HW WZ 10 166150 76

280 3,2 30 60 HW TR/TR 15 161136 45

280 3,2 32 96 HW FZ/TR 5 165725 58

280 3,45 45 60 HW FZ/TR 10 165675 51

280 4,4 30 48 HW KON/FZ 5 165640 49

280 4,55 30 60 HW FZ/TR 10 165678 51

280 4,55 45 84 HW WZ 10 165684 51

280 4,8 45 72 HW KON/WZ 5 165581 48

280 4,95 45 84 HW WZ 10 165685 51

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

300 1,7 30 96 HW WZ 10 058521 29

300 2,2 30 120 HW FZFA/FZFA -5 060276 62

300 2,2 30 80 HW FZFA/FZFA 0 163535 80

300 2,4 30 48 HW WZ 10 163117 27

300 2,4 30 96 HW WZ 10 163118 27

300 2,8 30 30 HW FZ 25 163555 17

300 2,8 80 28 HW WZ 15 163578 16

300 2,8 80 28 HW WZFA 15 165310 18

300 2,8 80 48 HW TR/TR 15 165311 18

300 2,8 80 30 HW FZ 25 163556 17

300 3,0 30 72 HW FZFA/FZFA 5 161005 63

300 3,0 30 96 HW FZFA/FZFA 5 161006 63

300 3,0 50 100 HW WZ/WZ/FZ 10 161266 70

300 3,2 30 96 HW FZ/TR -5 161380 61

300 3,2 30 96 HW FZ/TR -5 161381 61

300 3,2 30 36 HW WZ -5 165513 23

300 3,2 30 60 HW WZ -5 165514 23

300 3,2 30 96 HW WZ -5 165515 23

300 3,2 30 72 HW FZ/TR -5 165825 60

300 3,2 30 96 HW FZ/TR -5 165826 60

300 3,2 30 120 HW FZ/TR -5 165827 60

300 3,2 30 96 HW FZ/TR 5 161360 59

300 3,2 30 96 HW FZ/TR 5 161361 59

300 3,2 30 72 HW KON/FZ 5 165641 49

300 3,2 30 72 HW FZ/TR 5 165726 58

300 3,2 30 96 HW FZ/TR 5 165727 58

300 3,2 30 8 DP P 5 190305 83

300 3,2 30 72 HW FZ/TR 10 163005 34

300 3,2 30 96 HW FZ/TR 10 163006 34

300 3,2 30 36 HW WZ 10 163119 27

300 3,2 30 48 HW WZ 10 163120 27

300 3,2 30 72 HW WZ 10 163121 27

300 3,2 30 96 HW WZ 10 163122 27

300 3,2 30 72 HW TR/TR 15 161138 45

300 3,2 30 72 HW TR/TR 15 161139 45

300 3,2 30 72 HW TR/TR 15 163370 44

300 3,2 30 24 HW FZ 20 165111 19

300 3,2 30 28 HW WZ 20 166077 20

300 3,2 32 72 HW FZ/TR -5 165828 60

300 3,2 32 96 HW FZ/TR -5 165829 60

300 3,2 32 120 HW FZ/TR -5 165830 60

300 3,2 70 24 HW WZ 20 165201 15

300 3,4 80 28 HW

FZ 15 165312 18

300 3,5

30 96 HW WZ -5 161330 24

300 3,5 30 96 HW WZ -5 161331 24

300 3,5 30 96 HW WZ 5 163200 28

300 3,5 30 14 HW FZ 20 166051 20

300 3,5 30 20 HW FZ 25 165010 14

300 3,5 70 20 HW FZ 25 165011 14

300 3,5 80 20 HW FZ 25 165012 14

300 3,6 30 20 HW FZ/TR 10 163500 65

300 3,6 30 42 HW FZ/TR 10 163501 65

300 4,0 30 24 HW FZ 20 165102 19

300 4,0 80 28 HW TR/TR 15 165313 18

300 4,0 80 48 HW TR/TR 15 165314 18

300 4,3 30 48 DP KON/FZ 10 190743 50

300 4,4 30 48 HW KON/WZ 5 165582 48, 54

300 4,4 30 60 DP HRFA 5 190666 63

300 4,4 30 60 HW TR/TR 15 161137 45,

53-54

300 4,4 30 48 HW WZ 15 163300 41, 54

1. Sawing Quick search

6

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

300 4,4 30 60 HW TR/TR 15 163369 44,

53-54

300 4,4 30 60 HW FZ/TR 15 163400 42, 54

300 4,4 30 60 DP TR/TR 15 190706 47

300 4,4 50 48 HW KON/WZ 5 165583 48

300 4,4 60 72 HW TR/TR 15 161140 45, 53

300 4,4 60 72 HW TR/TR 15 163371 44, 53

300 4,4 60 72 HW FZ/TR 15 163401 42, 53

300 4,4 65 72 HW KON/WZ 5 165584 48

300 4,4 65 48 HW KON/WZ 5 165585 48

300 4,4 65 60 HW TR/TR 15 161141 45, 55

300 4,4 65 60 HW TR/TR 15 163372 44, 55

300 4,4 65 60 HW FZ/TR 15 163402 42, 55

300 4,4 75 60 HW FZ/TR 15 163403 42

300 4,4 80 60 HW TR/TR 15 161142 45, 52

300 4,4 80 60 HW TR/TR 15 163373 44, 52

300 4,4 80 60 HW FZ/TR 15 163456 42, 52

300 4,55 30 72 HW WZFA 10 165682 51

300 4,55 65 72 HW WZFA 10 165683 51

300 5,0 30 20 HW FZ 25 165002 14

300 8,0 80 24 HW FZ 15 165258 13

303 3,2 30 60 HW HZ/DZ -5 163077 33

303 3,2 30 100 HW WZ/WZ/FZ 10 161201 30

303 3,2 30 68 HW HZ/DZ 10 161301 32

303 3,2 30 60 HW HZ/DZ 10 163054 33

303 3,2 30 60 DP DZ/TR 10 190673 67

303 3,2 30 96 DP DZ/TR 10 190674 67

303 3,2 30 60 DP HZFA/

WZFA

10 190698 31

303 3,2 30 60 DP HZFA/

WZFA

10 190728 71

303 3,5 30 96 HW WZ -5 163226 28

303 3,5 30 60 HW TR/TR 10 161028 64

303 3,5 30 60 HW HZ/DZ 10 163052 33

305 2,4 25,4 80 HW FZFA/FZFA 0 163536 80

305 3,2 30 60 HW WZ -5 165516 23

308 3,2 60 96 DP TR/TR 10 190746 47

308 3,2 60 96 HW TR/TR 15 161143 45

308 3,2 60 96 HW FZ/TR 15 163404 42

310 4,4 60 72 HW TR/TR 15 161144 45

310 4,4 60 72 HW FZ/TR 15 163405 42

315 3,0 30 48 HW WZ 15 166152 76

315 3,2 30 72 HW WZ 10 166153 76

315 3,2 30 28 HW WZ 20 166151 76

320 3,2 30 84 HW FZ/TR 5 165728 58

320 3,2

70 28 HW WZ 20 165202 15

320 4,4 30 60 HW FZ/TR 15 163406 42, 53

320 4,4 50 60 HW TR/TR 15 161145 46

320 4,4 50 60 HW TR/TR 15 163374 44

320 4,4 60 72 HW TR/TR 15 163394 44

320 4,4 65 60 HW TR/TR 15 161146 46, 55

320 4,4 65 60 HW TR/TR 15 163375 44

320 4,4 65 60 HW FZ/TR 15 163407 42, 55

320 4,4 75 60 HW TR/TR 15 163376 44

320 4,4 80 60 HW TR/TR 15 161147 46

320 4,4 80 60 HW TR/TR 15 163377 44

320 4,4 80 60 HW FZ/TR 15 163457 42

330 2,4 30 80 HW FZFA/FZFA 0 163537 80

330 3,2 30 96 HW FZ/TR -5 165831 60

330 3,2 32 96 HW FZ/TR -5 165832 60

340 4,4 80 72 HW TR/TR 15 161148 46, 52

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

340 4,4 80 72 HW TR/TR 15 163378 44, 52

340 4,4 80 72 HW FZ/TR 15 163458 42, 52

350 2,4 30 140 HW FZFA/FZFA -5 060279 62

350 2,8 30 30 HW FZ 25 163557 17

350 3,2 30 108 HW FZ/TR -5 161382 61

350 3,2 30 108 HW FZ/TR -5 161383 61

350 3,2 30 36 HW WZ -5 165517 23

350 3,2 30 60 HW WZ -5 165518 23

350 3,2 30 108 HW FZ/TR -5 165837 60

350 3,2 30 108 HW FZ/TR 5 161362 59

350 3,2 30 108 HW FZ/TR 5 161363 59

350 3,2 30 108 HW FZ/TR 5 165730 58

350 3,2 30 70 DP HZFA/

WZFA

10 190699 31

350 3,2 30 70 DP HZFA/

WZFA

10 190729 71

350 3,2 30 24 HW FZ 20 165113 19

350 3,2 30 32 HW WZ 20 166078 20

350 3,2 32 84 HW FZ/TR 5 165731 58

350 3,4 30 84 HW FZ/TR -5 165833 60

350 3,4 30 84 HW FZ/TR 5 165729 58

350 3,5 30 108 HW WZ -5 161332 24

350 3,5 30 108 HW WZ -5 161333 24

350 3,5 30 108 HW WZ -5 165519 23

350 3,5 30 96 HW FZFA/FZFA 5 161007 63

350 3,5 30 108 HW WZ 5 163201 28

350 3,5 30 110 HW WZ/WZ/FZ 10 161263 70

350 3,5 30 80 HW HZ/DZ 10 161302 32

350 3,5 30 84 HW FZ/TR 10 163007 34

350 3,5 30 108 HW FZ/TR 10 163008 34

350 3,5 30 72 HW HZ/DZ 10 163053 33

350 3,5 30 54 HW WZ 10 163123 27

350 3,5 30 72 HW WZ 10 163124 27

350 3,5 30 84 HW WZ 10 163125 27

350 3,5 30 108 HW WZ 10 163126 27

350 3,5 30 32 HW WZ 10 163134 27

350 3,5 30 24 HW TR 10 166025 82

350 3,5 30 72 DP DZ/TR 10 190749 67

350 3,5 30 72 HW WZ 15 165976 69

350 3,5 30 12 HW FZ 20 163025 35

350 3,5 30 16 HW FZ 20 166052 20

350 3,5 70 28 HW WZ 20 165203 15

350 3,6 30 16 HW WZ 15 165975 69

350 3,6 40 108 HW FZ/TR -5 165838 60

350 3,8 30

84 HW FZ/TR -5 165834 60

350 3,8

30 24 HW FZ/TR 10 163502 65

350 3,8 30 48 HW FZ/TR 10 163503 65

350 3,8 30 48 HW FZFA/FZFA 10 165925 66

350 3,8 32 84 HW FZ/TR -5 165835 60

350 3,8 40 84 HW FZ/TR -5 165836 60

350 4,0 30 24 HW FZ 25 165013 14

350 4,0 80 24 HW FZ 25 165014 14

350 4,4 30 70 DP HRFA 5 190667 63

350 4,4 30 72 HW WZ/FA 15 161029 64

350 4,4 30 72 HW TR/TR 15 161149 46,

52-55

350 4,4 30 54 HW WZ 15 163301 41, 52,

54-55

1. Sawing Quick search

7

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

350 4,4 30 72 HW WZ 15 163302 41, 52,

54-55

350 4,4 30 72 HW TR/TR 15 163379 44,

52-55

350 4,4 30 72 HW FZ/TR 15 163408 42,

52-55

350 4,4 30 72 DP TR/TR 15 190707 47,

52-55

350 4,4 30 24 HW FZ 20 165104 19

350 4,4 60 72 HW WZ/FA 15 161030 64

350 4,4 60 72 HW TR/TR 15 161150 46,

52-53

350 4,4 60 72 HW WZ 15 163304 41,

52-53

350 4,4 60 72 HW TR/TR 15 163380 44,

52-53

350 4,4 60 72 HW FZ/TR 15 163409 42,

52-53

350 4,4 60 72 DP TR/TR 15 190708 47,

52-53

350 4,4 75 72 HW TR/TR 15 161151 46

350 4,4 75 72 HW TR/TR 15 163395 44

350 4,4 75 72 HW FZ/TR 15 163410 42

350 4,4 80 54 HW WZ 15 163305 41

350 4,4 80 72 HW FZ/TR 15 163454 42

350 4,55 75 72 HW FZ/TR 10 165679 51

350 5,0 30 24 HW FZ 25 165003 14

350 5,0 80 24 HW FZ 25 165004 14

355 2,4 25,4 80 HW FZFA/FZFA 0 163538 80

355 3,0 30 120 HW WZ/WZ/FZ 10 161202 30

355 3,2 30 72 HW WZ -5 165520 23

355 3,2 30 16 HW WZ 20 166154 76

355 3,2 30 32 HW WZ 20 166155 76

355 4,4 30 72 HW WZ 15 163306 41, 53

355 4,4 65 72 HW TR/TR 15 161152 46, 55

355 4,4 65 72 HW TR/TR 15 163381 44, 55

355 4,4 65 72 HW FZ/TR 15 163412 42, 55

355 4,4 75 72 HW FZ/TR 15 163413 42

355 4,4 80 72 HW TR/TR 15 161153 46, 55

360 4,4 30 72 HW TR/TR 15 161154 46, 54

360 4,4 30 72 HW TR/TR 15 163382 44, 54

360 4,4 30 72 HW FZ/TR 15 163414 42, 54

360 4,4 65 72 HW FZ/TR 15 163415 42, 55

370 3,5 30 108 HW WZ 10 165338 25

370 3,8 30 96 HW FZ/TR 5 165732 58

370 4,4 30 72 HW TR/TR 15 161155 46

370 4,4 30 72 HW FZ/TR 15 163416 42

380 3,8 32 108 HW FZ/TR -5 165839 60

380 4,4 30 72 HW TR/TR 15 161156 46

380 4,4 30 72 HW WZ 15 163319 41

380 4,4 30 72 HW

TR/TR 15 163383 44, 52

380 4,4

50 72 HW TR/TR 15 161157 46

380 4,4 50 72 HW TR/TR 15 163396 44

380 4,4 50 72 HW FZ/TR 15 163417 42

380 4,4 60 72 HW TR/TR 15 161158 46, 53

380 4,4 60 72 HW TR/TR 15 163384 44, 53

380 4,4 60 72 HW FZ/TR 15 163418 42, 53

380 4,4 60 72 DP TR/TR 15 190709 47

380 4,4 65 72 HW TR/TR 15 163386 44

380 4,4 65 72 HW FZ/TR 15 163461 42

380 4,4 75 72 HW FZ/TR 15 163420 42

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

380 4,4 80 72 HW TR/TR 15 161160 46, 52

380 4,4 80 72 HW FZ/TR 15 163459 42, 52

380 4,8 60 84 HW WZ/FA 15 161031 64

380 4,8 60 72 HW TR/TR 15 161159 46, 53

380 4,8 60 54 HW WZ 15 163307 41, 53

380 4,8 60 72 HW TR/TR 15 163385 44, 53

380 4,8 60 72 HW FZ/TR 15 163419 42, 53

380 4,8 60 84 HW TR/TR 15 163750 44

380 4,8 60 72 DP TR/TR 15 190710 47

400 3,0 30 84 HW FZFA/FZFA 0 163539 80

400 3,2 30 130 HW WZ/WZ/FZ 20 161203 30

400 3,5 30 120 HW WZ -5 161334 24

400 3,5 30 120 HW WZ -5 161335 24

400 3,5 30 48 HW WZ 10 163127 27

400 3,5 30 60 HW WZ 10 163128 27

400 3,5 30 84 HW WZ 10 163129 27

400 3,5 30 96 HW WZ 10 163130 27

400 3,5 30 120 HW WZ 10 163131 27

400 3,5 30 120 HW WZ 10 165450 22

400 3,5 30 140 HW WZ 10 165464 22

400 3,5 30 14 HW FZ 20 163026 35

400 3,8 30 42 HW WZ -5 165521 23

400 3,8 30 60 HW WZ -5 165522 23

400 3,8 30 120 HW WZ -5 165523 23

400 3,8 30 96 HW FZ/TR -5 165840 60

400 3,8 30 96 HW FZ/TR 5 165733 58

400 3,8 30 28 HW FZ/TR 10 163504 65

400 3,8 30 54 HW FZ/TR 10 163505 65

400 3,8 30 28 HW TR 10 166026 82

400 3,8 32 96 HW FZ/TR -5 165841 60

400 3,8 32 96 HW FZ/TR 5 165734 58

400 3,8 40 96 HW FZ/TR -5 165842 60

400 3,8 50 96 HW FZ/TR -5 165843 60

400 3,8 50 96 HW FZ/TR 5 165735 58

400 4,0 30 28 HW FZ 20 165114 19

400 4,0 30 18 HW FZ 20 166053 20

400 4,0 30 36 HW WZ 20 166079 20

400 4,0 30 28 HW FZ 25 165015 14

400 4,0 70 24 HW WZ 20 165204 15

400 4,0 80 28 HW FZ 25 165016 14

400 4,4 30 80 DP HRFA 5 762339 63

400 4,4 30 60 HW FZFA/FZFA 10 165926 66

400 4,4 30 72 HW

WZ/FA 15 161032 64

400 4,4

30 72 HW TR/TR 15 161161 46,

53-55

400 4,4 30 60 HW WZ 15 163308 41,

53-55

400 4,4 30 72 HW WZ 15 163309 41,

53-55

400 4,4 30 72 HW TR/TR 15 163387 45,

53-55

400 4,4 30 72 HW FZ/TR 15 163421 43,

53-55

400 4,4 30 72 DP TR/TR 15 190711 47,

53-55

400 4,4 60 72 HW FZ/TR 15 163422 43

400 4,4 65 72 HW TR/TR 15 163388 45

400 4,4 75 72 HW TR/TR 15 161162 46

400 4,4 75 72 HW FZ/TR 15 163423 43

400 4,4 80 72 HW TR/TR 15 161163 46, 52,

55

1. Sawing Quick search

8

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

400 4,4 80 72 HW FZ/TR 15 163455 43, 52

400 5,0 30 28 HW FZ 20 165105 19

400 5,0 30 28 HW FZ 25 165005 14

400 5,0 80 28 HW FZ 25 165006 14

420 3,5 40 48 HW WZ -5 165524 23

420 3,8 30 108 HW FZ/TR -5 165844 60

420 3,8 30 96 HW FZ/TR 5 165736 58

420 3,8 40 108 HW FZ/TR -5 165845 60

420 4,8 60 72 HW TR/TR 15 161164 46

420 4,8 60 72 HW FZ/TR 15 163426 43

430 3,5 30 96 HW FZ/TR 5 165737 58

430 4,4 30 72 HW TR/TR 15 161165 46

430 4,4 30 72 HW WZ 15 163310 41, 52

430 4,4 30 72 HW FZ/TR 15 163427 43, 52

430 4,4 65 72 HW TR/TR 15 163389 45

430 4,4 75 72 HW TR/TR 15 161166 46

430 4,4 75 72 HW FZ/TR 15 163428 43

430 4,4 80 72 HW TR/TR 15 161167 46, 52,

55

430 4,4 80 72 HW TR/TR 15 163397 45

430 4,4 80 72 HW FZ/TR 15 163429 43, 52,

55

440 7,0 75 12 HW WZ 20 165326 25

450 3,0 30 120 HW WZ 20 058461 29

450 3,5 30 158 HW WZ 10 165465 22

450 3,6 30 140 HW WZ/WZ/FZ 20 161204 30

450 3,8 30 48 HW WZ -5 165525 23

450 3,8 30 108 HW FZ/TR -5 165846 60

450 3,8 30 110 HW FZ/TR 5 165738 58

450 3,8 30 66 HW WZ 10 163132 27

450 3,8 30 16 HW FZ 20 163027 35

450 3,8 32 108 HW FZ/TR -5 165847 60

450 3,8 32 96 HW FZ/TR 5 165739 58

450 4,0 30 34 HW FZ/TR 10 163506 65

450 4,0 30 32 HW TR 10 166027 82

450 4,0 30 28 HW FZ 20 165115 19

450 4,0 30 20 HW FZ 20 166054 20

450 4,0 30 42 HW WZ 20 166080 20

450 4,4 30 90 DP HRFA 5 190668 63

450 4,4 30 60 HW FZ/TR 10 165927 66

450 4,4 30 72 HW WZ/FA 15 161033 64

450 4,4 30 72 HW TR/TR 15 161168 46

450 4,4 30 54 HW WZ 15 163311 41

450 4,4 30 72 HW WZ 15 163312 41

450 4,4 30

72 HW FZ/TR 15 163430 43

450 4,4

30 28 HW FZ 25 165017 14

450 4,4 80 72 HW FZ/TR 15 163432 43

450 4,8 30 138 HW WZ 10 165451 22

450 4,8 30 72 HW FZ/TR 10 165680 51

450 4,8 60 72 HW WZ/FA 15 161034 64

450 4,8 60 72 HW TR/TR 15 161169 46, 53

450 4,8 60 72 HW TR/TR 15 163390 45, 53

450 4,8 60 72 HW FZ/TR 15 163431 43, 53

450 4,8 60 72 DP TR/TR 15 190712 47, 53

450 4,8 80 72 HW TR/TR 15 163398 45

450 4,8 80 72 HW FZ/TR 15 163433 43, 55

450 5,0 30 108 HW WZ 10 165452 22

450 5,0 30 28 HW FZ 20 165106 19

450 5,0 30 28 HW FZ 25 165007 14

460 4,4 30 48 HW FZFA/FZFA 10 165928 66

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

460 4,4 30 72 HW TR/TR 15 161170 46, 54

460 4,4 30 72 HW TR/TR 15 163391 45, 54

460 4,4 30 72 HW FZ/TR 15 163434 43, 54

470 4,4 75 96 HW FZ/TR 15 163435 43

470 4,8 70 72 HW TR/TR 15 163392 45

480 4,4 30 72 HW WZ 15 163313 41

480 4,4 30 72 HW FZ/TR 15 163436 43

480 4,8 60 72 HW FZ/TR 15 163437 43

480 4,8 80 72 HW FZ/TR 15 163438 43, 55

500 3,8 30 72 HW WZ 10 163133 27

500 4,0 30 36 HW TR 10 166028 82

500 4,0 30 150 HW WZ/WZ/FZ 20 161205 30

500 4,0 30 32 HW FZ 20 165116 19

500 4,0 30 24 HW FZ 20 166055 20

500 4,0 30 48 HW WZ 20 166081 20

500 4,0 32 96 HW FZ/TR 5 165741 58

500 4,0 32 120 HW FZ/TR 5 165742 58

500 4,4 30 54 HW WZ -5 165526 23

500 4,4 30 120 HW FZ/TR -5 165848 60

500 4,4 30 120 HW FZ/TR 5 165740 58

500 4,4 30 100 DP HRFA 5 762341 63

500 4,4 30 36 HW FZ/TR 10 163507 65

500 4,4 32 120 HW FZ/TR 5 165743 58

500 4,4 75 28 HW WZ 20 165328 25

500 4,8 30 144 HW WZ 10 165454 22

500 4,8 35 144 HW WZ 10 165455 22

500 4,8 60 72 HW TR/TR 15 163393 45

500 5,0 30 32 HW FZ 20 165107 19

500 5,0 30 28 HW WZ 20 165205 15

500 5,2 30 120 HW WZ 10 165453 22

500 5,2 30 60 HW WZ 15 163314 41, 53

500 5,2 30 60 HW FZ/TR 15 163439 43, 53

500 5,2 60 60 HW FZ/TR 15 163440 43

500 5,2 80 60 HW WZ 15 163315 41

500 7,0 75 14 HW WZ 20 165327 25

510 4,8 80 72 HW FZ/TR 15 163441 43

520 4,4 30 44 HW FZFA/FZFA 10 165929 66

520 4,4 30 72 HW WZ 15 163316 41, 54

520 4,4 30 72 HW FZ/TR 15 163442 43, 54

520 4,4 50 120 HW FZ/TR -5 165849 60

520 4,6 30 144 HW WZ 10 165456 22

520 4,8 30 72 HW TR/TR 15 161171 46, 54

520 4,8 30 72 HW

TR/TR 15 163399 45

520 4,8

60 72 HW FZ/TR 15 163443 43

520 4,8 70 72 HW FZ/TR 15 163444 43

520 5,4 60 72 HW WZ 20 165332 25

530 4,4 30 44 HW FZFA/FZFA 10 165930 66

530 4,8 80 72 HW FZ/TR 15 163460 43

550 4,0 30 132 HW FZ/TR -5 165850 60

550 4,0 30 160 HW WZ/WZ/FZ 20 161206 30

550 4,0 32 132 HW FZ/TR -5 165851 60

550 4,0 32 96 HW FZ/TR 5 165744 58

550 4,0 32 126 HW FZ/TR 5 165745 58

550 4,4 30 120 HW FZ/TR 5 165746 58

550 4,4 30 110 DP HRFA 5 762342 63

550 4,8 30 54 HW WZ 20 166082 20

550 5,0 30 96 HW WZ 10 165457 22

550 5,0 80 36 HW WZ 25 165206 15

550 5,2 30 160 HW WZ 10 165458 22

550 5,2 30 120 HW WZ 10 165459 22

1. Sawing Quick search

9

D

mm

SB

mm

BO

mm

Z QAL ZF SW

°

ID Page

550 5,2 30 60 HW WZ 15 163317 41

550 5,2 80 60 HW WZ 15 163318 41

555 5,2 55 54 HW WZ 20 165325 25

570 4,8 60 60 HW FZ/TR 22 163445 43

570 5,0 40 48 HW FZFA/FZFA 10 165931 66

600 3,8 30 36 HW WZ 20 166610 76

600 4,6 30 140 HW FZ/TR 5 165747 58

600 4,8 30 120 DP HRFA 5 762343 63

600 4,8 30 60 HW WZ 20 166083 20

600 5,0 32 132 HW FZ/TR 5 165748 58

600 5,2 30 138 HW FZ/TR -5 165852 60

600 5,4 30 172 HW WZ 10 165461 22

600 5,4 80 72 HW WZ 20 165333 25

600 5,4 80 42 HW WZ 25 165207 15

600 5,8 30 108 HW WZ 10 165460 22

600 5,8 60 60 HW FZ/TR 22 163446 43, 52

600 5,8 60 72 HW FZ/TR 22 163447 43, 52

600 6,0 30 48 HW WZ 15 057570 25

600 7,0 75 16 HW WZ 20 165329 25

620 5,5 40 36 HW FZFA/FZFA 10 165932 66

620 5,5 40 60 HW FZ/TR 10 165933 66

630 5,4 30 180 HW WZ 10 165462 22

640 5,4 30 36 HW WZ 20 165330 25

650 5,0 30 144 HW FZ/TR 5 165749 58

670 5,8 60 42 HW FZ/TR 22 163448 43

680 5,5 40 42 HW FZFA/FZFA 10 165934 66

680 6,2 40 60 HW FZ/TR 22 163449 43, 54

700 4,2 30 42 HW WZ 20 166611 76

700 4,8 30 60 HW WZ 20 166084 20

700 5,5 30 200 HW WZ 10 165463 22

700 6,0 30 72 HW WZ 15 165334 25

700 6,2 80 60 HW FZ/TR 22 163450 43

720 6,5 40 60 HW FZ/TR 22 163451 43, 54

730 6,2 60 60 HW FZ/TR 22 163452 43

750 6,0 30 72 HW WZ 15 165335 25

750 7,0 80 70 HW FZ/TR 22 163453 43

800 6,0 30 72 HW WZ 15 165336 25

850 8,0 30 60 HW WZ 20 165331 25

1. Sawing Quick search

10

1. Sawing

FZ

1.1 Solid wood cutting along grain

For splitting or edging timber, for cutting lamellae on horizontal and vertical spindles.

Softwood and hardwood, wet, frozen, dry or long fibre materials.

Edging, single blade, multi blade sawblades as well as sawblades with either one or

two spindles. Circular saw benches or moulders.

Application

Workpiece material

Machine

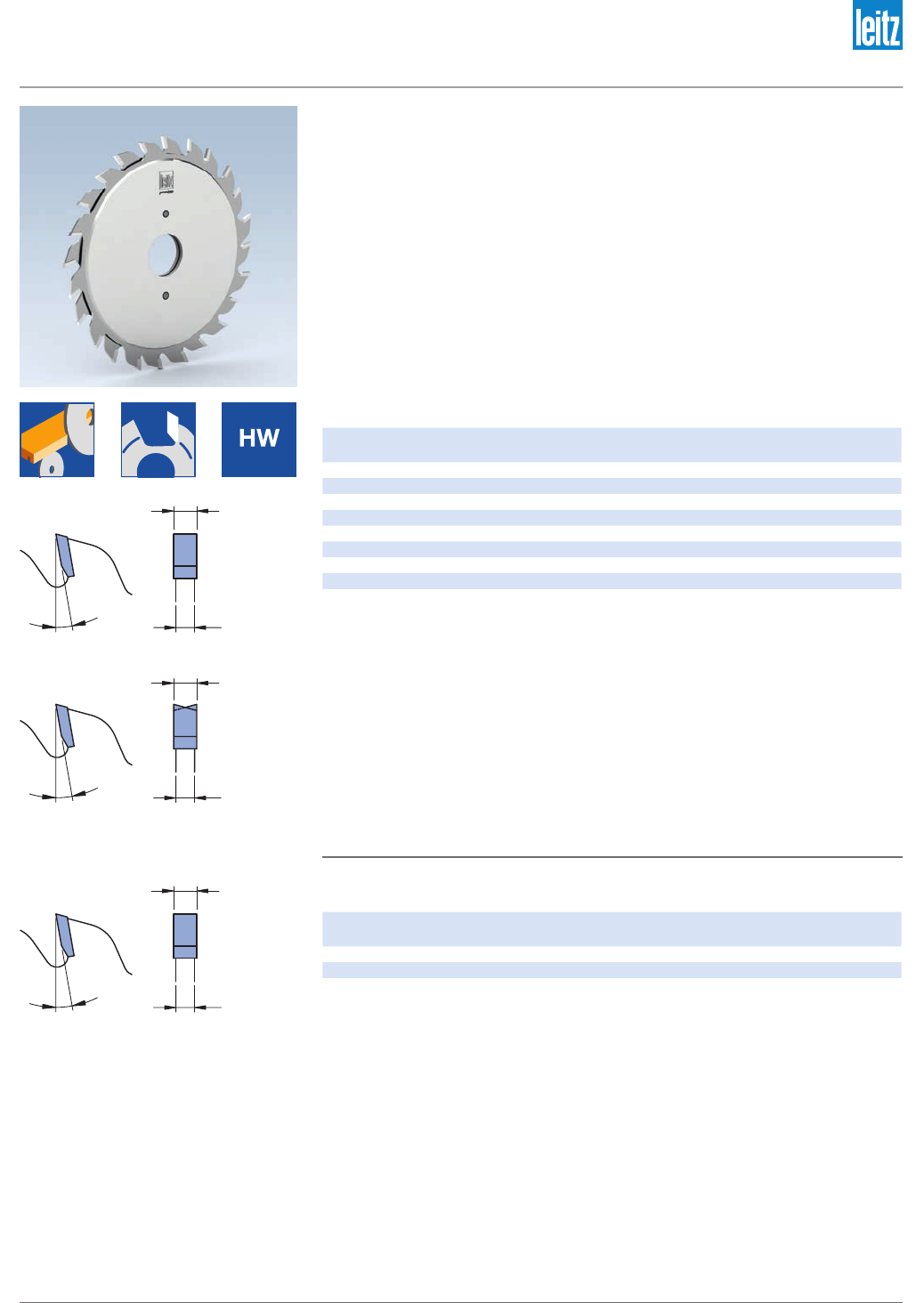

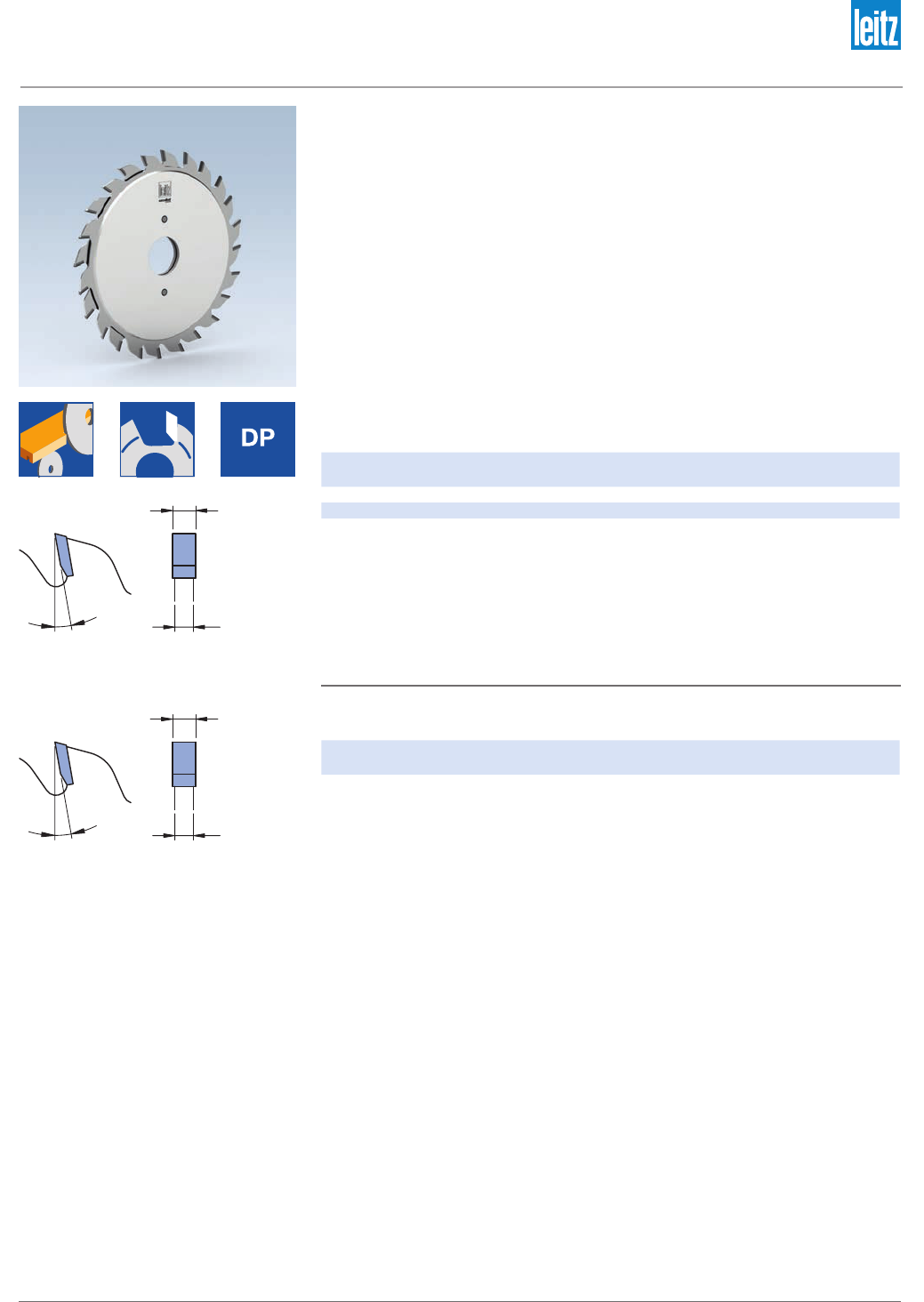

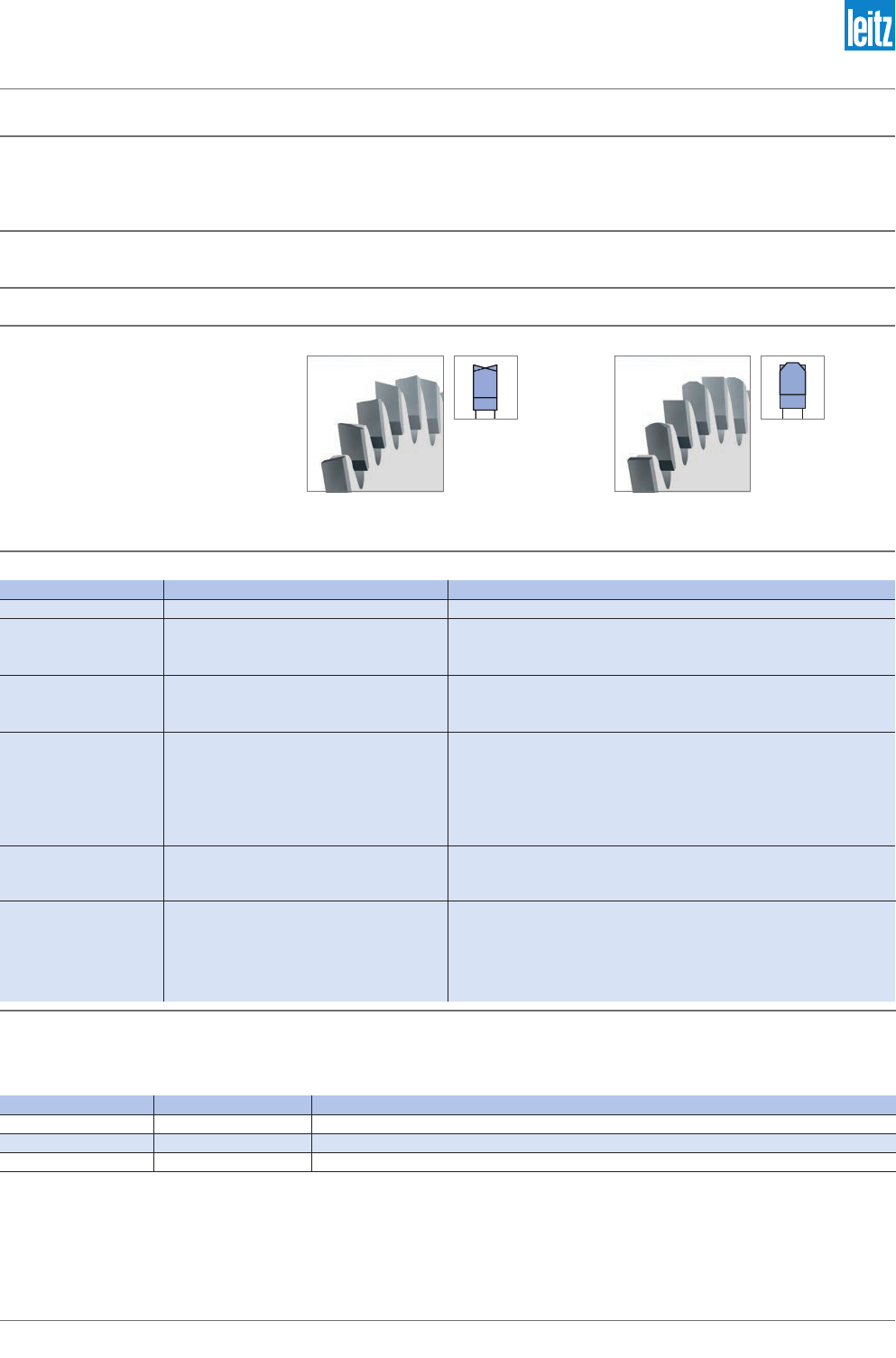

Tooth shape FZ (square teeth):

For multi-purpose application –

particularly suitable for wet and dry

wood.

WZ (alternative top bevel teeth):

Ideal for long-fibred wood.

Higher quality on the exit surface.

TR (trapezoidal teeth):

Recommended for cutting dry wood

with minimum marking.

30

40

50

60

70

1,2 < 1,4 1,4 < 1,6 1,8 — 2,01,6 < 1,8

80

Technical notes Recommendations:

– Mount thin kerf sawblades on hydro sleeves.

– Check the sawblade clamping flange diameter.

– Check the cutting height and the tooth progression (feed rate).

– Resharpen and clean resin residues regularly.

Thin kerf circular sawblades –

Cutting height depends on the sawblade cutting width SB.

Cutting height diagram

– Sawmill industry (laminating strips, lumber etc.).

– Solid board production (lamellos and core materials for multiple layer panels etc.).

– Parquet flooring industry (for core and surface materials, lamellos).

– Moulding products (mouldings, lippings, rulers etc.).

– Sport industry (skis, table tennis rackets etc.).

Thin kerf sawblades

Application area

Solid wood

Cutting width [mm]

Cutting height [mm]

11

1. Sawing 1.1 Solid wood cutting along grain

– Environmentally friendly use of resources.

– Reduced chips and dust.

– Optimised timber usage.

– More strips from workpiece with standard cuts.

Advantages

To avoid bending the sawblade, we recommend using wide sawblades or hoggers

on the motorside. Riving knives are recommended when cutting thin lamella; a split

machine table is necessary.

Machine types

Single or multi spindle multi blade

machines without automatic feed

Position of double keyways

for spiral arrangement of

circular sawblades

The saw spindle should have high precision bearings for accuracy.

Precise and stable feeding devices needed for bent, curved or twisted materials.

– Accurate adjustment of spindle and guide needed when sawing vertically

(top and bottom side spindles).

– For horizontal cutting, the thickness of riving knives depends on the cutting

width of the sawblades. The riving knives must be aligned 100% horizontal.

Multi spindle machines with

automatic feed (for horizontal

and vertical cutting)

1/3 of the tooth pitch 2/3 of the tooth pitch

12

Premium lamella cut - middle cut with extremely

reduced cutting width

Application:

For cutting strips and slats along grain on horizontal and vertical spindles.

Machine:

Moulders with/without forced guidance of workpieces. Application on single, double,

horizontal or vertical spindles.

Workpiece material:

Softwood and hardwood, dry up to 10 % wood moisture content, quality

category0to 1.

Technical information:

Noise-reduced and low vibration design due to irregular tooth pitch or odd number

of teeth. Cutting width reduction for high wood savings and efficient energy

utilisation. Continuous tool body without recess for max. cutting height. Different

number of teeth for optimal tooth feeds with different feed speed. Higher cutting

performance and less resinification due to special coating of the tool body. Use on

hydro sleeves or clamping arbors is recommended, as is the use of high precision

spacers to increase the performance of the saws. It is essential to pay attention to

the setting of machines with riving knives.

Middle cut

WK 100 2 21

D

mm

SB

mm

TDI

mm

BO

mm

BO

max

mm

NLA

mm

FLD

mm

Z ZF SW

°

WSS ID

180 1.3 0.8 60 70 3/10/75 100 32 FZ 20

057418

180 1.5 1.0 60 70 3/10/75 100 21 FZ 20

057443

180 1.8 1.2 60 70 3/10/75 100 21 FZ 20

057444

180 1.8 1.3 60 70 3/10/75 100 32 FZ 20

057412

200 1.5 1.0 60 80 3/10/75 120 21 FZ 20

057445

200 1.5 1.0 60 80 3/10/75 120 36 FZ 20

057421

200 1.8 1.2 60 80 3/10/75 120 21 FZ 20

057446

220 1.2 0.9 60 80 3/10/75 120 27 FZ 20

057475

220 1.2 0.9 65 80 3/11/80 120 24 FZ 20

057474

220 1.3 0.9 60 80 3/10/75 120 24 FZ 25

057476

220 1.3 0.9 60 80 3/10/75 120 32 FZ 25

057478

220 1.3 0.9 65 80 3/11/80 120 24 FZ 25

057477

220 1.3 0.9 65 80 3/11/80 120 32 FZ 25

057479

220 1.4 1.0 60 80 3/10/75 120 24 FZ 25

057480

220 1.4 1.0 60 80 3/10/75 120 32 FZ 20

057464

220 1.4 1.0 65 80 3/11/80 120 24 FZ 25

057481

220 1.4 1.0 65 80 3/11/80 120 32 FZ 20

057465

225 1.5 1.0 60 110 3/10/75 120 25 FZ 20

057447

225 1.6 1.2 60 110 3/10/75 130 32 FZ 25

057482

225 1.8 1.2 60 110 3/10/75 120 25 FZ 20

057448

225 2.0 1.4 40 110 3/10/75 120 40 FZ 20

163600

225 2.0 1.4 60 110 3/10/75 120 25 FZ 20

057449

250 1.7 1.2 60 120 3/10/75 140 25 FZ 20

057450

250 1.7 1.2 60 120 3/10/75 140 36 FZ 20

057433

250 2.0 1.4 60 120 3/10/75 140 25 FZ 20

057451

250 2.0 1.4 60 120 3/10/75 140 36 FZ 20

057434

1. Sawing

SB

TDISW

FZ

1.1 Solid wood cutting along grain

1.1.1 Circular sawblades thin kerf

;

available ex stock

□

available at short notice

Instruction manual visit www.leitz.org

13

Lamella cut - shoulder cut

Application:

For cutting along grain - shoulder cuts in combination with middle cut sawblades.

Machine:

Moulders with/without forced guidance of workpieces. Application on single, double,

horizontal or vertical spindles.

Workpiece material:

Softwood and hardwood, dry up to 10 % wood moisture content, quality

category0to 1.

Technical information:

Suitable for utilisation as a set in combination with thin kerf sawblades for middle

cuts. Solid design to increase the rigidity of the set. Higher cutting performance and

less resin formation by special coated toolbody.

Shoulder cuts

WK 100 2 21

D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

DKN

mm

FLD

mm

Z ZF SW

°

WSS ID

200 5.0 4.0 30 3/10/75 120 24 FZ 20

165250

220 5.0 4.0 30 3/10/75 120 24 FZ 20

165251

225 5.0 4.0 30 3/10/75 120 24 FZ 20

165252

225 5.0 4.0 60 3/10/75 120 40 FZ 20

165256

250 5.0 4.0 30 3/10/75 140 24 FZ 20

165253

250 5.0 4.0 30 3/10/75 140 36 FZ 20

165254

250 8.0 6.0 80 4/7/95

2/13/100

13/89 100 24 FZ 15

165257

300 8.0 6.0 80 4/7/95

2/13/100

13/89 100 24 FZ 15

165258

1. Sawing

SB

TDISW

FZ

1.1 Solid wood cutting along grain

1.1.1 Circular sawblades thin kerf

Technical information:

Suitable for utilisation as a set in combination with thin kerf sawblades for middle

cuts. Special cutting edge geometry for cut pitch and lower cutting forces. For cutting

pressure reduction and reduction of burn marks even at lower feed rates.Higher

cutting performance and less resin formation by special coated toolbody.

Shoulder cuts - reduced number of teeth

WK 150 2, WK 150 2 21

D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

FLD

mm

Z ZF SW

°

WSS ID

180 3.8 3,0 60 3/10/75

3/11/80

100 24 WZ 20

165255

200 3.8 3,0 60 3/10/75

3/11/80

100 24 WZ 20

165259

220 3.8 3,0 60 3/10/75

3/11/80

120 24 WZ 20

165260

220 3.8 3,0 65 3/10/75

3/11/80

120 24 WZ 20

165261

220 3.8 3,0 60 3/10/75

3/11/80

120 24 WZ 20

165262

225 3.8 3,0 60 3/10/75

3/11/80

120 24 WZ 20

165263

250 3.8 3,0 60 3/10/75

3/11/80

120 24 WZ 20

165264

SB

TDISW

WZ

Solid wood

Board, coated

Board, uncoated

Non-ferrous metals

Plastics

Mineral materials

Composites

Steel, thin-walled

14

Lamella cut with internal and external wiper teeth

Application:

For cutting along grain - shoulder and trimming cuts.

Machine:

Edging, single blade, multi blade saws as well as saws with one or two spindles.

Workpiece material:

Softwood and hardwood wet, frozen, dry. Long fibre materials (poplar, balsa etc.)

Technical information:

With two internal and external (from D 280 mm) raker blades. Solid design especially

for edge cuts. Large lateral tooth protrusions. For universal use in dry, wet and frozen

soft and hard woods.Higher cutting performance and less resinification due to

special coating of the tool body.

Square and shoulder cut

WK 150 2

D

mm

SB

mm

TDI

mm

BO

mm

BO

max

mm

NLA

mm

DKN

mm

FLD

max

mm

Z ZF SW

°

WSS ID

250 4.4 2.8 30 80 KNL 130 18 FZ 25

165000

250 4.4 2.8 80 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

130 18 FZ 25

165001

300 5.0 3.2 30 80 KNL 110 20 FZ 25

165002

350 5.0 3.2 30 100 KNL 130 24 FZ 25

165003

350 5.0 3.2 80 100 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

130 24 FZ 25

165004

400 5.0 3.2 30 120 KNL 150 28 FZ 25

165005

400 5.0 3.2 80 120 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

150 28 FZ 25

165006

450 5.0 3.2 30 120 KNL 160 28 FZ 25

165007

1. Sawing

SB

TDISW

FZ

1.1 Solid wood cutting along grain

1.1.2 Circular sawblades with wiper teeth

Application:

For cutting along grain - middle cuts.

Middle cut

WK 100 2 43

D

mm

SB

mm

TDI

mm

BO

mm

BO

max

mm

NLA

mm

DKN

mm

FLD

max

mm

Z ZF SW

°

WSS ID

250 3.5 2.2 30 80 KNL 130 18 FZ 25

165008

250 3.5 2.2 80 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

130 18 FZ 25

165009

300 3.5 2.2 30 80 KNL 110 20 FZ 25

165010

300 3.5 2.2 70 21x83 110 20 FZ 25

165011

300 3.5 2.2 80 23x90

13x89

110 20 FZ 25

165012

350 4.0 2.8 30 100 KNL 130 24 FZ 25

165013

350 4.0 2.8 80 100 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

130 24 FZ 25

165014

400 4.0 2.8 30 120 KNL 150 28 FZ 25

165015

400 4.0 2.8 80 120 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

150 28 FZ 25

165016

450 4.4 3.0 30 120 KNL 160 28 FZ 25

165017

SB

TDISW

FZ

;

available ex stock

□

available at short notice

Instruction manual visit www.leitz.org

15

Lamella cut with internal and external wiper teeth

Application:

For cutting along grain - middle cuts.

Machine:

Edging, single blade, multi blade saws as well as saws with one or two spindles.

Workpiece material:

Softwood and hardwood, dry up to 15% wood moisture content. Long fibre materials

(poplar, balsa etc.).

Technical information:

With two external and two or four internal wiper teeth.Tooth shape WZ best suited

for cuts in long-fibred woods such as poplar. Lower power consumption due to tooth

shape WZ.Higher cutting performance and less resinification due to special coating

of the tool body.

Middle cut

WK 150 2

D

mm

SB

mm

TDI

mm

BO

mm

BO

max

mm

NLA

mm

DKN

mm

Z ZF SW

°

WSS ID

250 3.2 2.2 70 20,6/83 20 WZ 20

165200

300 3.2 2.2 70 80 20,6/83 24 WZ 20

165201

320 3.2 2.2 70 80 20,6/83 28 WZ 20

165202

350 3.5 2.5 70 100 20,6/83 28 WZ 20

165203

400 4,0 2.8 70 100 20,6/83 24 WZ 20

165204

500 5,0 3.5 30 100 KNL 28 WZ 20

165205

550 5,0 3.2 80 2/13/100 36 WZ 25

165206

600 5.4 3.8 80 2/13/100 42 WZ 25

165207

1. Sawing

SB

TDISW

WZ

1.1 Solid wood cutting along grain

1.1.2 Circular sawblades with wiper teeth

Solid wood

Board, coated

Board, uncoated

Non-ferrous metals

Plastics

Mineral materials

Composites

Steel, thin-walled

16

Lamella cut with external wiper teeth Premium

Application:

For cutting of thin slats on horizontal spindles.

Machine:

Edging, single blade, multi blade saws as well as saws or moulders with one or

two spindles.

Workpiece material:

Softwood, dry up to 10% wood moisture content.

Technical information:

With two external raker blades giving better chip ejection. Higher cutting

performance and less resinification due to special coating of the tool body. Special

limitor shape for protection of the teeth when used in woods with loose knots and

in cracked woods.

Middle cut

WK 100 2, WK 150 2

D

mm

SB

mm

TDI

mm

BO

mm

DKN

mm

Z ZF SW

°

WSS ID

200 2.0 1.4 30 24 FZ 20

163575

250 2.0 1.4 80 19/89 36 WZ 15

163576

250 2.4 1.6 80 19/89 32 WZ 15

163577

300 2.8 1.8 80 19/89 28 WZ 15

163578

1. Sawing

SB

TDISW

FZ

SB

TDISW

WZ

1.1 Solid wood cutting along grain

1.1.2 Circular sawblades with wiper teeth

;

available ex stock

□

available at short notice

Instruction manual visit www.leitz.org

17

Lamella cut with internal wiper teeth Premium - reduced

cutting width

Application:

For cutting of thin slats on horizontal spindles.

Machine:

Edging, single blade, multi blade saws as well as saws or moulders with one or two

spindles.

Workpiece material:

Softwood and hardwood, dry up to 10% wood moisture content.

Technical information:

With internal raker blades for better dimensional stability. Efficient energy and wood

utilisation due to reduced cutting widths. Special limitor shape (up to D 250 mm)

to protect the teeth when used in wood with loose knots and cracked wood. From

D 300 mm large gullet areas for better chip ejection.Higher cutting performance and

less resinification due to special coating of the tool body.

Middle cut

WK 100 4 , WK 100 2

D

mm

SB

mm

TDI

mm

BO

mm

BO

max

mm

DKN

mm

Z ZF SW

°

WSS ID

200 2.4 1.6 30 24 FZ 25

163560

200 2.4 1.6 40 60 24 FZ 20

163550

220 2.4 1.6 30 24 FZ 25

163559

220 2.4 1.6 40 80 24 FZ 20

163551

250 2.4 1.6 30 24 FZ 20

163558

250 2.4 1.6 40 90 24 FZ 20

163552

250 2.4 1.6 70 21/83 24 FZ 20

163553

250 2.4 1.6 80 19x89

13x89

24 FZ 20

163554

300 2.8 1.8 30 100 30 FZ 25

163555

300 2.8 1.8 80 19x89

13x89

30 FZ 25

163556

350 2.8 1.8 30 110 30 FZ 25

163557

1. Sawing

SB

TDISW

FZ

1.1 Solid wood cutting along grain

1.1.2 Circular sawblades with wiper teeth

Lamella cut with internal and external wiper teeth

Premium - reduced cutting width

Application:

For cutting of thin slats on vertical spindles.

Machine:

Edging, single blade, multi blade saws as well as saws or moulders with one or two

spindles.

Workpiece material:

Softwood and hardwood, dry up to 10% wood moisture content.

Technical information:

With two external and internal raker blades for increased stability also for larger

cutting depths. Efficient energy and wood utilization through reduced cutting widths.

Higher cutting performance and less resinification through special coating of the tool

body.

Middle cut

WK 100 2

D

mm

SB

mm

TDI

mm

BO

mm

BO

max

mm

NLA

mm

FLD

max

mm

Z ZF SW

°

WSS ID

250 2.4 1.6 60 80 3/10/75 100 24 FZ 20

163700

250 2.4 1.6 60 80 3/10/75 120 40 FZ 20

163701

270 2.4 1.6 60 80 3/10/75 120 28 FZ 20

163702

Solid wood

Board, coated

Board, uncoated

Non-ferrous metals

Plastics

Mineral materials

Composites

Steel, thin-walled

18

Lamella cut for glueable cuts

Application:

For cutting along grain - glueable middle and lamellae cuts on horizontal spindles.

Machine:

Single blade, multi blade saws as well as saws and moulders with one or two

spindles.

Workpiece material:

Softwood and hardwood, dry up to 10% wood moisture content.

Technical information:

Special tooth geometry for gluable cutting areas. Noise-reduced design due to

irregular tooth pitch. Continuous tool body without recess. Increased cutting

performance and less resinification through special coating of the tool body.

Middle cut

WK 100 2, WK 150 2, WK 152 2, WK 158 2

Machine D

mm

SB

mm

TDI

mm

BO

mm

BO

max

mm

NLA

mm

DKN

mm

Z ZF SW

°

WSS ID

180 2.2 1.4 30 60 3/10/75 18 FZ 15

165300

180 2.4 1.6 30 60 3/10/75 24 FZ 15

165301

200 2.4 1.6 30 60 3/10/75 18 FZ 15

165302

200 2.4 1.6 30 60 3/10/75 24 FZ 15

165303

225 2.4 1.6 30 60 3/10/75 24 FZ 15

165304

225 2.8 2.0 30 60 3/10/75 24 FZ 15

165305

240 2.8 2.0 40 60 3/10/75 24 FZ 15

165306

Raimann 250 2.4 1.6 80 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

40 WZ 15

165309

250 2.8 2.0 30 100 3/10/75 24 FZ 15

165307

250 2.8 2.0 70 100 21/80 24 FZ 15

165308

Raimann 300 2.8 1.8 80 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

28 WZFA 15

165310

Raimann 300 2.8 2.0 80 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

48 TR/TR 15

165311

Raimann 300 3.4 2.2 80 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

28 FZ 15

165312

Raimann 300 4.0 2.8 80 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

28 TR/TR 15

165313

Raimann 300 4.0 2.8 80 6/5.5/91

4/6.6/95

2/13/100

19/89

13/89

48 TR/TR 15

165314

1. Sawing

SB

TDISW

WZ

SB

TDISW

TR/TR

1.1 Solid wood cutting along grain

1.1.3 Circular sawblades without wiper teeth

;

available ex stock

□

available at short notice

Instruction manual visit www.leitz.org

19

Lamella cut

Application:

For cutting along grain - shoulder and trimming cuts.

Machine:

Edging, single blade, multi blade saws as well as saws with one or two spindles.

Workpiece material:

Softwood and hardwood wet and dry.

Technical information:

Large gullet area and large lateral tooth protrusion. Solid desing particularly for edge

cuts. For universal use in dry and wet soft and hard woods. Design without raker

blades. Partially suitable for larger cutting depths and the use in frozen woods.

Shoulder and square cut

WK 100 2

D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

Z ZF SW

°

WSS ID

250 4.0 2.6 30 KNL 18 FZ 20

165101

300 4.0 2.6 30 KNL 24 FZ 20

165102

350 4.4 3.0 30 KNL 24 FZ 20

165104

400 5.0 3.2 30 KNL 28 FZ 20

165105

450 5.0 3.2 30 KNL 28 FZ 20

165106

500 5.0 3.2 30 KNL 32 FZ 20

165107

1. Sawing

SB

TDISW

FZ

1.1 Solid wood cutting along grain

1.1.3 Circular sawblades without wiper teeth

Middle cut

WK 100 2

D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

Z ZF SW

°

WSS ID

200 3.2 2.2 30 KNL 18 FZ 25

165108

210 3.2 2.2 30 KNL 18 FZ 20

165109

250 3.2 2.2 30 KNL 18 FZ 20

165110

300 3.2 2.2 30 KNL 24 FZ 20

165111

350 3.2 2.2 30 KNL 24 FZ 20

165113

400 4.0 2.8 30 KNL 28 FZ 20

165114

450 4.0 2.8 30 KNL 28 FZ 20

165115

500 4.0 2.8 30 KNL 32 FZ 20

165116

SB

TDISW

FZ

Solid wood

Board, coated

Board, uncoated

Non-ferrous metals

Plastics

Mineral materials

Composites

Steel, thin-walled

20

1. Sawing

SB

TDISW

FZ

1.1 Solid wood cutting along grain

1.1.3 Circular sawblades without wiper teeth

Sizing solid wood along grain

Application:

For cutting along grain - sizing wood.

Machine:

Edging, single blade, multi blade saws as well as saws with one or two spindles.

Workpiece material:

Softwood and hardwood, dry up to 15% wood moisture content.

Technical information:

Design with chip thickness limitation for limited chip removal per tooth and reduced

feed speeds.

Circular sawblade FZ with thickness limitation

WK 100 2

D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

Z ZF SW

°

WSS ID

250 3.2 2.2 30 KNL 18 FZ 20

166050

300 3.5 2.4 30 KNL 14 FZ 20

166051

350 3.5 2.4 30 KNL 16 FZ 20

166052

400 4.0 2.8 30 KNL 18 FZ 20

166053

450 4.0 2.8 30 KNL 20 FZ 20

166054

500 4.0 2.8 30 KNL 24 FZ 20

166055

Universal sizing

Application:

For multi-purpose application in solid wood.

Machine:

Trimming and cross cutting saws.

Workpiece material:

Softwood and hardwood wet and dry.

Technical information:

Design with chip thickness limitation for limited chip removal per tooth and reduced

feed speeds. Tooth shape WZ for cuts in long-fibred woods such as poplar and for

cuts in wet woods. Lower power consumption due to tooth shape WZ. Also suitable

for cuts across the grain.

Circular sawblade WZ with thickness limitation

WK 150 2

D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

Z ZF SW

°

WSS ID

250 3.2 2.2 30 KNL 24 WZ 20

166076

300 3.2 2.2 30 KNL 28 WZ 20

166077

350 3.2 2.2 30 KNL 32 WZ 20

166078

400 4.0 2.8 30 KNL 36 WZ 20

166079

450 4.0 2.8 30 KNL 42 WZ 20

166080

500 4.0 2.8 30 KNL 48 WZ 20

166081

550 4.8 3.5 30 KNL 54 WZ 20

166082

600 4.8 3.5 30 KNL 60 WZ 20

166083

700 4.8 3.5 30 KNL 60 WZ 20

166084

SB

TDISW

WZ

;

available ex stock

□

available at short notice

Instruction manual visit www.leitz.org

21

1. Sawing 1.2 Solid wood cutting across grain

For trim, cross, mitre and sizing cuts.

Solid wood with or without coating, plywood, glulam, solid surface materials.

Combined table, mitre, radial, underfloor and optimising saws.

Application area

Workpiece material

Machine

Application

WZ (alternative top bevel teeth):

Multi purpose tooth shape, economical

to purchase and maintain – suitable for

solid wood and wood derived materials.

The cutting force of sawblades with a

positive cutting angle and the spindle

below the workpiece or for sawblades

with a negative cutting angle and the

spindle above the workpiece. Press the

material onto the table.

On radial saws, the use of sawblades

with a negative cutting angle cutting

against the feed is obligatory (see

EN 1870-17). The negative cutting angle

presses the material onto the table.

Tooth shape

Table

Cutting pressure

right

wrong

right 3 – 5

wrong

Table

Cutting

pressure

22

Trimming at high feed rates

Application:

For trimming and cross cutting with cycle times of 0.3 - 1.0 sec.

Machine:

Cross, trimming and optimising saws.

Workpiece material:

Solid wood wet and dry across grain, solid wood profiles across grain.

Technical information:

For fast cross-cutting, sizing and optimizing machines. Large lateral tooth clearance

and a high number of teeth. Stable corner angle of 20° for tear-free cutting results

and long tool life.

Trimming at high feed rates

WK 150 2

Machine D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

Z ZF SW

°

WSS ID

Dimter,

System

TM

400 3.5 2.8 30 2/10/60

2/15/63

2/10/150

2/10/198

120 WZ 10

165450

Dimter,

System

TM

400 3.5 2.8 30 2/10/60

2/15/63

2/10/150

2/10/198

140 WZ 10

165464

Dimter,

System

TM

450 3.5 2.8 30 2/10/60

2/15/63

2/10/150

2/10/198

158 WZ 10

165465

Dimter 450 4.8 3.5 30 2/10/60

2/15/63

138 WZ 10

165451

Dimter 450 5.0 3.2 30 2/10/60

2/15/63

108 WZ 10

165452

Dimter,

System

TM

500 4.8 3.5 30 2/10/60

2/15/63

2/10/150

2/10/198

144 WZ 10

165454

Dimter 500 4.8 3.5 35 2/10/60

2/15/63

144 WZ 10

165455

□

Dimter 500 5.2 3.2 30 2/10/60

2/15/63

120 WZ 10

165453

Dimter 520 4.6 3.4 30 2/10/60

2/15/63

144 WZ 10

165456

Dimter 550 5.0 3.2 30 2/10/60

2/15/63

96 WZ 10

165457

Dimter 550 5.2 3.2 30 2/10/60

2/15/63

120 WZ 10

165459

Dimter,

System

TM

550 5.2 3.2 30 2/10/60

2/15/63

2/10/150

2/10/198

160 WZ 10

165458

Dimter 600 5.4 4.0 30 2/10/60

2/15/63

172 WZ 10

165461

Dimter 600 5.8 4.0 30 2/10/60

2/15/63

108 WZ 10

165460

Dimter 630 5.4 4.0 30 2/10/60

2/15/63

180 WZ 10

165462

Dimter 700 5.5 4.0 30 2/15/63 200 WZ 10

165463

1. Sawing

SB

TDISW

WZ

1.2 Solid wood cutting across grain

1.2.1 Circular sawblades for optimising saws

;

available ex stock

□

available at short notice

Instruction manual visit www.leitz.org

23

Trimming with negative cutting angle

Application:

For trimming and cross cutting - positioning of workpiece under the sawblade.

Machine:

Cross, trimming, mitre and radial saws as well as double mitre cutting saws.

Workpiece material:

Softwood and hardwood wet and dry, laminated veneer lumber (e.g. plywood,

multiplex plywood).

Technical information:

Especially for machines with positioning of the saw shaft above the workpiece.

Negative cutting angle for improved workpiece clamping.

Circular sawblade WZ with neg. cutting angle

WK 160 2

D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

Z ZF SW

°

WSS ID

300 3.2 2.4 30 KNL 36 WZ -5

165513

300 3.2 2.4 30 KNL 60 WZ -5

165514

300 3.2 2.4 30 KNL 96 WZ -5

165515

305 3.2 2.4 30 KNL 60 WZ -5

165516

350 3.2 2.4 30 KNL 36 WZ -5

165517

350 3.2 2.4 30 KNL 60 WZ -5

165518

350 3.5 2.8 30 KNL 108 WZ -5

165519

355 3.2 2.4 30 KNL 72 WZ -5

165520

400 3.8 2.8 30 KNL 42 WZ -5

165521

400 3.8 2.8 30 KNL 60 WZ -5

165522

400 3.8 2.8 30 KNL 120 WZ -5

165523

420 3.5 2.8 40 48 WZ -5

165524

450 3.8 2.8 30 KNL 48 WZ -5

165525

500 4.4 3.2 30 KNL 54 WZ -5

165526

1. Sawing

SB

TDISW

WZ

1.2 Solid wood cutting across grain

1.2.2 Circular sawblades WZ with neg. cutting angle

Solid wood

Board, coated

Board, uncoated

Non-ferrous metals

Plastics

Mineral materials

Composites

Steel, thin-walled

24

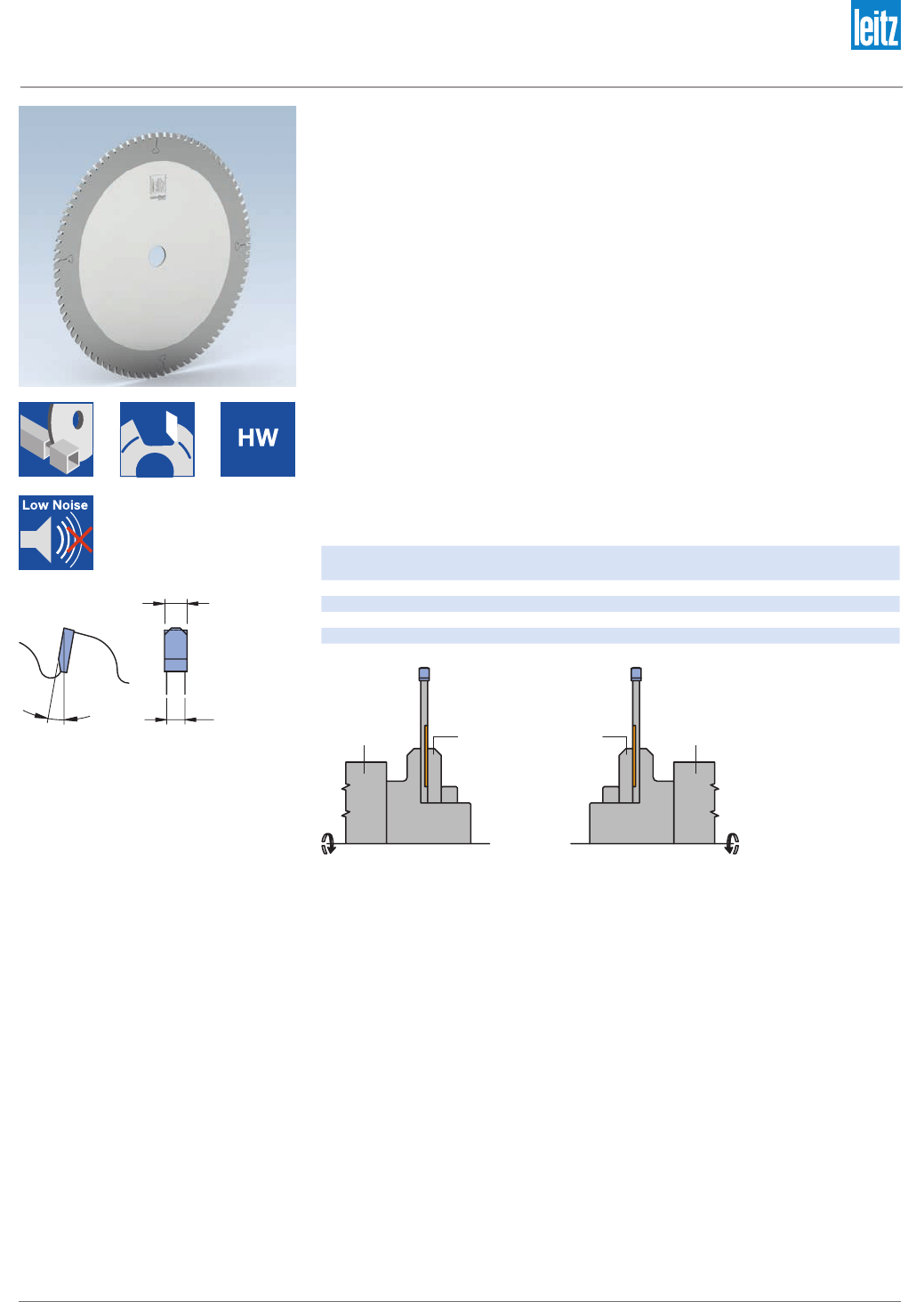

Trimming with negative cutting angle Excellent

Application:

For trimming and cross cutting - positioning of workpiece under the sawblade.

Machine:

Cross, trimming, mitre and radial saws as well as double mitre cutting saws.

Workpiece material:

Softwood and hardwood wet and dry, laminated veneer lumber (e.g. plywood,

multiplex plywood).

Technical information:

Especially for machines with positioning of the saw shaft above the workpiece.

Negative cutting angle for improved workpiece clamping.Excellent design.

Vibration-damping composite construction of the tool body by means of steel foil.

Extreme noise reduction even with increasing dulling of the tool.

Circular sawblade WZ with neg. cutting angle

WK 180 2

D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

Z ZF SW

°

Foil WSS ID

300 3.5 2.6 30 KNL 96 WZ -5 left

161330

300 3.5 2.6 30 KNL 96 WZ -5 right

161331

350 3.5 2.6 30 KNL 108 WZ -5 left

161332

350 3.5 2.6 30 KNL 108 WZ -5 right

161333

400 3.5 2.6 30 KNL 120 WZ -5 left

161334

400 3.5 2.6 30 KNL 120 WZ -5 right

161335

1. Sawing

SB

TDISW

WZ

Motor

Loose flange =

foil side

Motor

Loose flange =

foil side

1.2 Solid wood cutting across grain

1.2.2 Circular sawblades WZ with neg. cutting angle

;

available ex stock

□

available at short notice

Instruction manual visit www.leitz.org

25

Trimming, crossing and mitre cuts

Application:

For cross cutting, trimming and angled cuts.

Machine:

Cross and trimming saws and CNC controlled joinery machines,

cross cutting twin saws.

Workpiece material:

Solid wood beams wet and dry, cross-glued beams.

Technical information:

Tooth shape for universal use and with large lateral tooth clearance.

Circular sawblade WZ

WK 150 2

Machine D

mm

SB

mm

TDI

mm

BO

mm

NLA

mm

Z ZF SW

°

WSS ID

Weinmann 240 3,0 2,0 40 8/6/52 30 WZ 15

165337

Weinmann 370 3.5 2.5 30 KNL 108 WZ 10

165338

Routech 440 7,0 4,0 75 6/9/100

2/8,5/100

12+2+2 WZ 20

165326

Routech 500 4.4 3.2 75 2/8,5/100

6/10,6/100

28+2+2+2 WZ 20

165328

Routech 500 7,0 4,0 75 6/9/100

2/8,5/100

14+2+2+2 WZ 20

165327

Essetre 520 5.4 3.5 60 8/6,5/100 72 WZ 20

165332

Weinmann 555 5.2 3,6/6 55 6/7/75 54+2+2 WZ 20

165325

Essetre 600 5.4 3.5 80 8/9,5/120 72 WZ 20

165333

600 6,0 4,0 30 2/14/400 48 WZ 15

057570

Routech 600 7,0 4,0 75 6/9/125

2/8,5/125

16+2+2+2 WZ 20

165329

Uniteam 640 5.4 3.6 30 8/6,5/160

8/6,5/130

4/10,5/90

36+2+2 WZ 20

165330

700 6,0 4.4 30 72 WZ 15

165334

750 6,0 4.4 30 72 WZ 15

165335

800 6,0 4.4 30 72 WZ 15

165336

Uniteam 850 8,0 6,0 30 8/6,5/160

8/6,5/130

4/10,5/90

60+2+2+2 WZ 20

165331

1. Sawing

SB

TDISW

WZ

1.2 Solid wood cutting across grain

1.2.3 Circular sawblades for joinery machines

Solid wood

Board, coated

Board, uncoated

Non-ferrous metals

Plastics

Mineral materials

Composites

Steel, thin-walled

26

1. Sawing 1.3 Sizing

For cross cutting and sizing; grooving and cutting also possible if safety regulations

are followed.

Solid wood, wood derived materials, synthetic materials and light metals.

Table saws, sizing machines with/without scoring saw, vertical panel sizing saws and

twin sizing saws.

Suitable for cutting from below against the feed. On vertical panel sizing machines

and twin saw dimension saws cutting from either below or above against the feed.

Working process

Workpiece materials

Machines

Application

The positive cutting angle presses the

material onto the table for sawblades

with a positive cutting angle and the

spindle below the workpiece.

The negative cutting angle presses the

material onto the table for sawblades

with a negative cutting angle and the

spindle above the workpiece.

On radial saw machines, sawblades must be used (see EN1870-17) with a negative

cutting angle against the feed.

Table

Cutting pressure

right

wrong

right 3 – 5

wrong

Table

Cutting

pressure

WZ (alternative top bevel teeth):

Multi-purpose tooth shape, economical

to purchase and maintain. Ideal for

chipboard, veneered chipboard, solid

wood, block board, plywood.

Tooth shape

FZ/TR (square/trapezoidal teeth):

Tooth shape for plastic and foil coated

wood derived materials.

TR/TR (trapezoidal/trapezoidal teeth):

Best tooth shape for cutting hard and

abrasive coatings – can be altered from

the existing FZ/TR shape.

HZ/DZ (hollow face/inverted V teeth):

Tooth shape for high cutting quality

on plastic coated materials, with high

upper and lower edge quality on

machines without a scoring saw.

WZ/WZ/FZ (alternative/square teeth):

Tooth shape for solid wood, glulam and

coated or veneered wood derived mate-

rials; tear-free cutting edges and high

cut quality. Combinations of tooth forms

(WZre, WZli, WZre, WZli, FZ).

27

Sizing Premium

Application:

For sizing and cross cutting with/without scoring.

Machine:

Table and sizing saws.

Workpiece material:

Solid wood across grain, chipboard and fibre materials, laminated veneer lumber

(e.g. plywood, multiplex plywood).

Technical information:

Premium design with vibration-damping laser ornaments (from D 200 mm). Marked

dimensions with irregular tooth pitch (UT) for noise reduction and improved running

behaviour.