221 S. BERRY ST., BREA, CA. 92821 TEL (714) 529-1935 FAX (714) 529-7203

INSTALLATION,

OPERATION AND

MAINTENANCE

MANUAL

Publication No. IOM 108.2

February, 2007

TABLE OF CONTENTS

PAGE

INSPECTION 2

INSTALLATION

LOCATING CONDENSING UNITS 2

LOCATING UNIT COOLERS 3

UNIT COOLER MINIMUM DISTANCES 4

FIELD WIRING 5

REFRIGERANT PIPING 5

LEAK TESTING 6

EVACUATION 6

CHARGING & START-UP 7

GENERAL MAINTENANCE 7

TYPICAL FIELD WIRING DIAGRAMS 8

HIGH SIERRA SEQUENCE OF OPERATIONS 9

TROUBLE SHOOTING GUIDE 11-12

REPLACEMENT PARTS 13-16

www.russellcoil.com

INSPECTION

When the equipment is received, check the quantity of cartons and crates against the bill of

lading.

· Inspect all containers for visible damage.

· Report any damage or shortages to the freight company immediately.

· It is the customer's responsibility to file a freight claim.

· Check the unit name plates to verify that the voltage and phase is correct before installation.

Installation and maintenance should be performed by qualified personnel who are familiar

with local codes and regulations. Installers should have previous experience with this type of

equipment.

CAUTION: Avoid contact with sharp edges and coil surfaces.

INSTALLATION

LOCATING CONDENSING UNITS

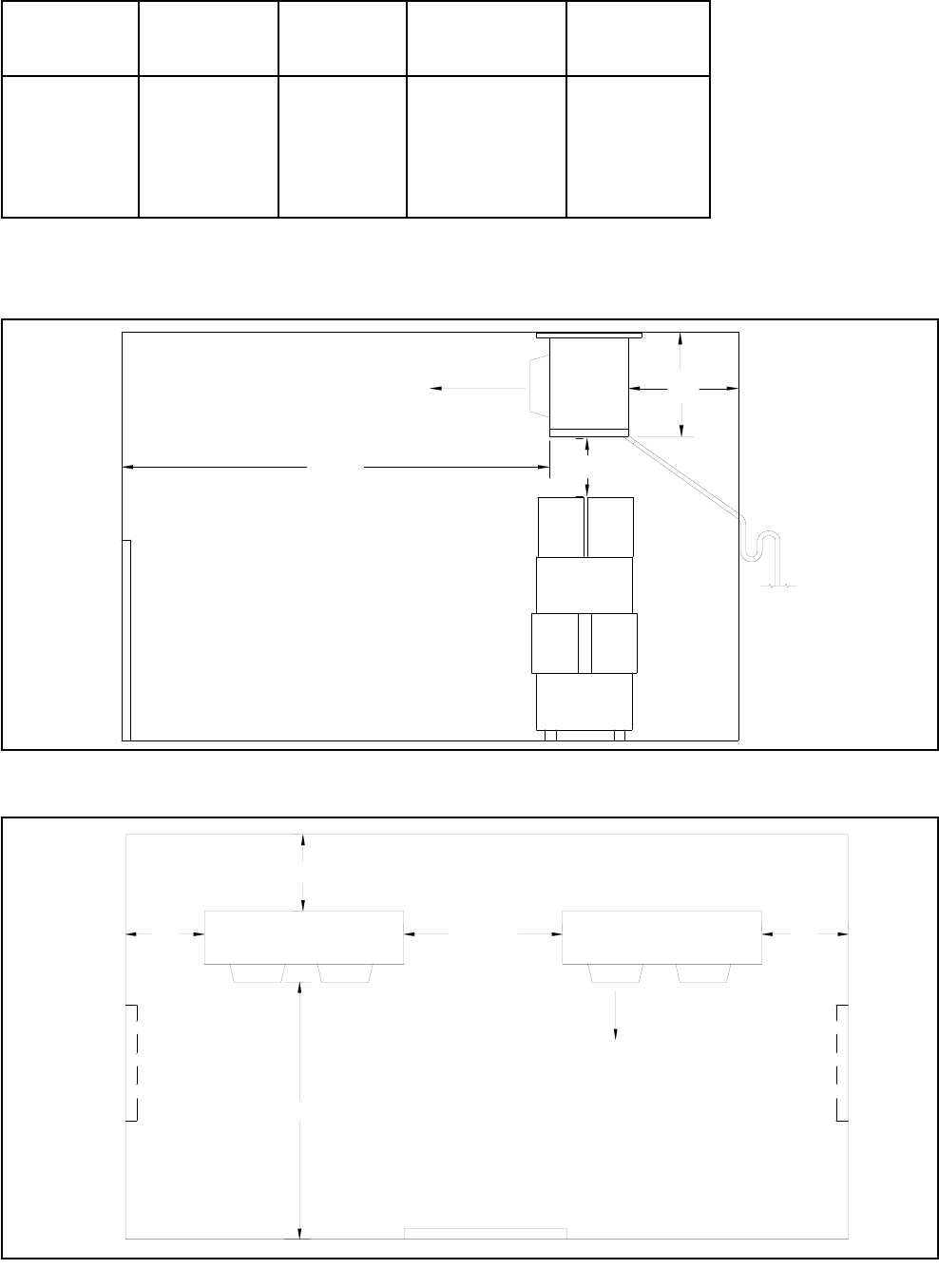

Condensing unit - Minimum clearances

Do not locate condensing units so that they are bordered on three or more sides by tall

obstructions. Condensing units should be positioned so that the airflow through the con-

denser is the same as the prevailing winds. If strong variable winds are common, a wind

deflector should be used on the discharge side of the unit. Be certain that there is adequate

room around the unit for regular inspection and service. For multiple unit sites, do not locate

units where the air discharge from one condensing unit will enter into the air intake of other

units.

Roof mounted condensing units should be located above supporting walls, over storage

areas or spaces not sensitive to noise or vibration. They must be adequately supported.

Pad mounted condensing units should be installed a minimum of 4 inches above ground

level, away from windows, doors and other areas where noise may be a problem. All units

must be level when mounted.

Minimum

HP Dimensions (in)

ABC

1/2 - 2 60 24 36

3 - 6 72 24 36

8 - 15 72 30 48

20 - 40 48 48 48

C

B

B

A

CONDENSING UNIT

PLAN VIEW

Discharge air Intake air

2

Table 1

Drawing 1

3

CONDENSING UNIT INSTALLATION (continued.)

Condensing units with spring mounted compressors are shipped with retainers under the

compressor feet to prevent damage during shipment. For Copeland H and K body

compressors, remove the retainers and loosen the mounting nut to allow 1/16” clearance

between the nut and rubber spacer. For 3HP and larger units, the mounting nuts must be

removed to insert the rubber spacer. Insert the rubber spacer over the mounting studs,

replace the nut and tighten to within 1/16” of the spacer. DO NOT

TIGHTEN THE NUTS

AGAINST THE SPACER OR FOOT.

Units with iso-pad mounted compressors are shipped with the mounting nuts tight. These

should be checked to make certain that they have not loosened during shipment.

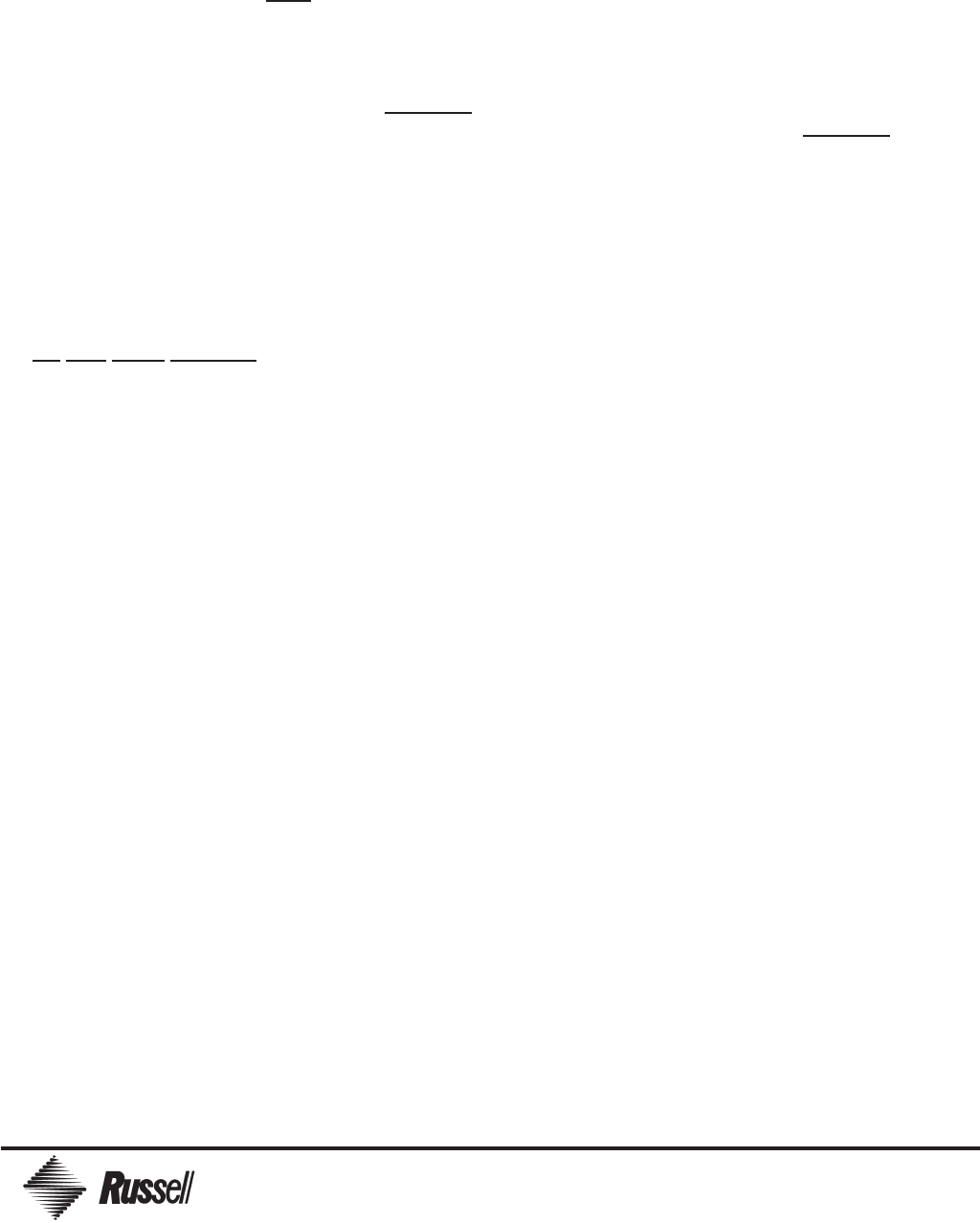

LOCATING AND MOUNTING UNIT COOLERS

Determine the best location for the unit in the walk-in cooler or freezer. Consider the air pat-

tern required to cover the entire space. For High Sierra Systems with two unit coolers, locate

the unit coolers so that the piping runs from the suction and liquid line tees are equal in size

and length.

Do not restrict the inlet or outlet air stream. Place the unit cooler as far as possible from

any door openings. Direct the discharge air stream towards the door whenever possible.

This will help to prevent warm, moist air from being drawn into the coil (Drawings 2, 3 and

Table 2). Adequate clearances should be maintained around the unit cooler to allow for

proper airflow through the unit and for regular maintenance and service to be preformed.

For all Hot Gas defrost unit coolers, ensure that the drain pan is in contact with the Hot Gas

drain pan loop after installation. If the drain pan is removed for any reason, verify

that it has

physical contact with the defrost loop when replaced.

The drain line should be pitched a minimum of 4" per foot to allow proper drainage and

should exit the room as quickly as possible. Do not reduce the drain line size. Do not locate

line bends, elbows or drain traps within the refrigerated space. All drain lines must be

trapped outside of the enclosure where the temperature is never below 35 degrees. Drain

lines should run to an open drain and should never be attached directly to a sewage or waste

line. Drain lines must be protected from possible freezing. Freezer units must have copper

drain lines that are heated and insulated.

Remove all packaging materials before lifting the unit into position. Be certain that the unit is

not sitting on the drain fitting or refrigerant connections. All-Temp units should be hung using

5/16" minimum diameter, stainless steel support rods or fasteners at all hanging slots. Use

minimum 3/8" hanger rods for Inter-Temp and Ultra-Temp models.

Tighten all fasteners securely. All units must be positioned level, flush with the ceiling and all

gaps must be properly caulked. Allow minimum clearances on all sides of the unit cooler(s) as

indicated in Table 2 (next page).

Recommended Minimum Dimensions

Table 2 Dimensions are in inches.

* Absolute minimum Distance

** 15’ is adequate clearance for these models

12"

min.

Slope Drain

line 4" per foot

and trap.

Air

5 x H*

obstruction

free area

door

H*

Drawing 2

Unit cooler Air intake* Side Air discharge Unit to

Height clearance clearance clearance floor

H 1 x H 1 x H 2 x H 5 x H

15 15 15 30 75

19 19 19 38 95

25 25 25 50 125

32 32 32 64 160

50 50 50 100 180**

Door

H* H*

H*

5 x H*

Back Wall

Front Wall

Alternate

Door

Location

Alternate

Door

Location

Air

Keep air discharge

area free from

obstruction

2 x H*

Discharge

Drawing 3

4

5

FIELD WIRING

All field wiring must be done in compliance with local and national electrical codes. Use only

properly sized Copper conductors. A system wiring diagram is located inside the condensing

unit control box. Wire components as indicated on the diagram. The equipment nameplates are

marked with electrical characteristics. All field wiring should enter the equipment through

electrical conduit bushings. Note: All units must be grounded.

Before applying power to the units, check all connections to ensure they have not come loose

during shipment. Be

certain that the power is disconnected before tightening any electrical

connections. Disconnect switches and evaporator branch circuit protection are supplied by the

equipment installer and must conform to governing electrical codes. Air defrost systems are

wired so that the evaporator fans run continuously. For electric defrost and High Sierra systems,

the evaporator fans are cycled off during the defrost and re-cooling period.

Electric defrost unit coolers are supplied with a temperature sensing defrost termination switch

that will end the defrost at a preset coil temperature. (Recommended time clock settings for

electric defrost are 2 defrosts per day, with a twenty minute fail safe setting. Adjust according to

job site conditions. Fewest possible defrost

s for the shortest possible duration are desirable.)

A high limit control is provided to prevent overheating if there is a component failure. A fan delay

control is installed to allow the water condensate on the fins to freeze before the evaporator fan

motors start. A pumpdown cycle is mandatory for all systems.

For both Sierra and High Sierra systems, a liquid line solenoid is factory installed and wired to

each unit cooler terminal board (multiple evap systems receive multiple solenoid valves). Follow

the system wiring diagram (provided in the condensing unit). Connection to

TB1-44 must be

made to assure proper pumpdown function. The room thermostat is mounted on the unit cooler

for single evaporator systems and supplied loose for multiple evaporator systems. Follow the

system wiring diagram supplied in the condensing unit.

REFRIGERANT PIPING

Condensing units and unit coolers are thoroughly cleaned and dehydrated at the factory. Use

only ACR (refrigeration grade) tubing that is dehydrated and sealed. Only use WROT Copper

fittings, cast fittings are a source of refrigerant leaks. All liquid and suction elbows must be long

radius types for minimum pressure drop. Refrigerant lines must be properly supported to

prevent vibration and breakage. Tube clamps should have a gasketed liner to prevent abrasion of

the tubing. Sierra and High Sierra must not exceed more then a 100’ refrigerant line run.

Install all piping and components in accordance with local and national codes. Make refrigerant

connections by using only hard or Silver bearing solder such as Silfos, Stay-Silv or higher Silver

content brazing material. Slowly purge dry nitrogen through the tubing while brazing to prevent

the formation of Copper oxide scale.

LIQUID LINE

Refer to the current ASHRAE Refrigeration Systems and Applications Handbook for assistance

in determining appropriate liquid line sizes.

Horizontal and vertical liquid lines are normally the same diameter. However, pressure loss due

to vertical lift may lead to flash gas that can inhibit proper TXV (and system) performance if not

properly accounted for. Under sizing the liquid line can result in flash gas while over sizing the

liquid line will unnecessarily increase the system charge requirement.

Sierra and High Sierra condensing units include Russell’s patented finned receiver

®

, which is

integrated into the air-cooled condenser. This finned receiver

®

also acts as an efficient liquid

sub-cooler. An additional liquid to suction heat exchanger is not normally required. The liquid

line must be insulated to obtain the maximum benefits of the subcooled liquid.

SUCTION LINES

The suction line and it’s components must be carefully selected and installed. The suction line

must be sized to maintain a balance of adequate refrigerant velocity, to allow for good oil

return, and a low pressure drop that will prevent excessive capacity loss. The optimal line

size will result in a reasonable refrigerant velocity and a minimum pressure drop. Total suction

line pressure loss should not exceed 2

o

F equivalent loss. For best system performance, the

suction line should be insulated.

Suction line risers should be no larger in diameter than the horizontal pipe run. Refer to the

current ASHRAE Refrigeration Systems and Applications Handbook for correct suction line

and riser sizing. Horizontal suction line runs should slope in the direction of flow, 1 inch per

ten feet of length. All suction lines should be insulated as soon as they exit the refrigerated

space. Install a 1/4-inch schrader fitting near the evaporator outlet to assist in accurate super-

heat readings. All suction line risers should be trapped to facilitate oil return. Additional

P-Traps are required for every 15 feet of elevation. Oil traps should be the same diameter as

the suction line riser that it attaches to.

MULTIPLE EVAPORATOR PIPING

High Sierra systems involving multiple evaporators require that piping runs be of equal length

to each evaporator. The line runs must be of equivelent length from the bull-head tees to

each unit cooler. This will ensure proper distributon of hot gas to each unit cooler during the

defrost cycle. Reference the drawing below for further clarification.

60c.o.

Sight

Glass

Defrost

Termination

Set: 250c.i.

Relief

Valve

Valve

200c.o.

Set: 90c.i.

Fan Cyle

Control

Check

Valve

Suction Filter

Liquid

Valve

Shutoff

Compressor

Condensing Unit

Reversing

Condenser Coil

TXV

Power

Supply

Insulation

Evaporator

Evaporator

TXV

Drain Pan Circuit

Valves

Check

Sol. Valve

Liquid

Check Valve

Drain Pan Circuit

Check

Valves

Check Valve

Liquid

Sol. Valve

TXV

Bi-Flow

Liquid Filter

Size For Total System Capacity

Size for one evaporator capacity.

Must be equal length or equivelent pressure drop.

Tee must be oriented to split hot gas defrost.

6

LEAK TESTING

After all refrigerant connections are made, add the proper system refrigerant until the pressure

is 25 to 35 PSI. Then pressurize with dry nitrogen up to 120 PSI. Always use a pressure

reducing regulator. Wait 30 minutes for the refrigerant to reach all parts of the system. Use an

electronic leak detector to inspect all connections and system components. Repair any leaks

that are found and re-check until all leaks are eliminated. Leave the system pressurized over

night. Once the system is tight, it must be evacuated before charging.

7

EVACUATION

Proper installation procedures must include a deep evacuation of the system. A clean/dry

system is essential when charging refrigerant. Open all service valves. The high vacuum

method is the most effective procedure for assuring a clean and dry system. It requires the

use of a two-stage high vacuum pump, an electronic high-vacuum gauge and 3/8" minimum

OD copper tubing. Use a high vacuum sealant on all lines and connections. Clean and dry

DEEP

VACUUM OIL is essential for proper system evacuation.

This step is required

FOR SIERRA/HIGH SIERRA SYSTEMS:

Evacuation access fitting:

AREA 1: From the compressor service valve (including the compressor head)

through the condenser up to the liquid line module; Connecting to the port on

the compressor discharge valve gets this area.

AREA 2: From the liquid line module to the liquid line solenoid; connecting to

the liquid line “King” valve port gets this area on Sierra system. The connection

will not properly evacuate area 1, above, since evacuation would have to be

pulled through the check valve in the module, which will have about 1 PSI

restriction. However, on High Sierra systems a pressure tap at the connection

for the terminator pressure control evacuates the liquid line since this connection

is downstream of the module.

AREA 3 : From the liquid line solenoid to the compressor (including the crankcase)

connecting to the suction service port gets this area.

The need for this clarification has arisen from the fact that some systems have

experienced high head pressure because non-condensables were left in the system

when these procedures were not followed.

All systems - continued

Connect the vacuum lines to both the high and low-pressure sides of the system. Run the

vacuum pump until the gauge reaches 500 microns for newly installed systems. With the

pump still running, shut off the high vacuum line valve. The vacuum gauge should not exceed

(1500 microns or less ) after two minutes once the pump is closed off, though the pressure

will increase slightly even on the most leak-free system. Open the compressor service valves

and pull a continuous vacuum for a minimum of 4 hours. Pulling the vacuum overnight is

highly recommended (mandatory for 5 HP systems and larger). Do not allow the system to

stand at high vacuum without the vacuum pump operating. Do not start the compressor while

the system is under a vacuum.

CHARGING

Both Sierra and High Sierra systems are designed to operate with minimum refrigerant

charge and minimum head pressures. - Low head pressures are normal at low ambient

conditions.

Make the charging line connection with a hose that is purged of air

, through a filter drier.

Break the vacuum with the proper system refrigerant. Charge liquid refrigerant into the high

side of the system. This should enable the system to operate. Add refrigerant charge as nec-

essary to achieve a clear sight glass

with the system close to normal operating condition,

whether it is winter or summer

. Ambient temperature is not relevant to the charging proce-

dure.

IMPORTANT! Sierra and High Sierra systems are critical charge systems.

Be careful, DO

NOT OVERCHARGE!

8

CHARGING

continuation...

Refrigerant can be added most rapidly by introducing liquid directly into the liquid line down

stream of the liquid line valve. Close the liquid line intermittently and add refrigerant directly

into the port on the side of the liquid line valve until the sight glass is clear.

NOTE: Some new refrigerants require liquid charging only.

Be extra diligent not to log liquid in the accumulator, if one is present in the system. An

accumulator is not recommended for Sierra or High Sierra systems. They can negatively

impact the charging procedure of these systems. Liquid build-up in the accumulator may

result from improper charging. Once in the accumulator the refrigerant returns very slowly.

Depending on how much is accumulated, how much frost is on the accumulator (frost acts

as an insulator so the refrigerant boils off slower), ambient temperature, etc..., this excess

refrigerant can cause significant problems.

START UP

Install gauges on the system to check both high and low pressures. Using the gauges, verify

that the low-pressure control is properly set (3 PSI cut out, 15 PSI cut in).

Pump down the system by closing the liquid line solenoid and the service valve to verify that

there is no objectionable increase in head pressure.

Be certain that the fan cycling control is properly adjusted. At the correct setting the cut-out

setting should be 30 PSI above the design suction pressure. The cut-in setting should be 30

PSI above the cut out pressure.

THIS STEP

IS REQUIRED FOR HIGH SIERRA ONLY

Move the high side gauge to the defrost termination schrader valve on the suction

line and start a defrost cycle. Verify that the defrost terminates at 250 PSI, adjust

the termination control if necessary. Set the time clock defrost fail-safe to

A MAXIMUM OF 10 MINUTES and an initial setting of 2 defrosts per day.

Check the evaporator superheat after the system has run long enough to reach a balanced

state. Low temperature systems normally operate most efficiently at a superheat settings that

range from 6 to 8 degrees at design room temperature. Medium temperature rooms normally

operate from 8 to 10 degree evaporator superheat. Adjust expansion valves only if necessary.

GENERAL MAINTENANCE

Disconnect all electrical power to the unit before inspecting or cleaning. Unit coolers and

condensing units should be checked periodically and cleaned of all dirt or grease accumulation.

Fan blades and guards may require more frequent cleaning. Remove debris from the

condenser coil using a brush or vacuum cleaner. All fan motors are life lubricated and do not

require periodic oiling. Do not use ammonia or other cleaning agents that are corrosive or

react with Copper or Aluminum.

If the liquid line filter is replaced High Sierra system, it must be replaced with a Bi-Flow filter

.

TYPICAL FIELD WIRING DIAGRAMS

SIERRA SYSTEMS

Air Defrost

Systems

Condensing unit

Condensing unit

Electric Defrost

Single unit cooler

1 phase motors

3 phase heaters

Condensing unit

Condensing unit

HIGH SIERRA COUNTER FLOW DEFROST

Single unit cooler

1 Phase motor(s)

Condensing unit

— —

Field wiring

TB1 - Terminal block # 1

TB2 - Terminal block # 2

C6 - Heater contactor

LLS - Liquid line solenoid

EF - Evaporator fan motor(s)

T’stat - Room thermostat

DT - Defrost Termination

FD - Fan Delay Control

Condensing unit

2 unit coolers

1 Phase motors

Legend (all diagrams)

*See page 5 for wiring instructions. 9

Electric Defrost

Two unit coolers

1 phase motors

1 phase heaters

Electric Defrost

Single unit cooler

1 phase motors

1 phase heaters

10

HIGH SIERRA - Sequence of operation.

Refrigeration cycle

The High Sierra counter flow defrost system is unique in design. It operates like most conventional

systems during the refrigeration cycle. As cooling is called for, the compressor,

condenser fan(s), evaporator fans and liquid line solenoid valve are all energized.

Refrigerant vapor exits the compressor discharge port, moves through the High Sierra reversing

valve and into the air-cooled condenser. As ambient air flows through the condenser, the refriger-

ant vapor gives up it's heat, becomes liquid and moves through the patented Sierra Finned

Receiver

®

and liquid sub-cooler.

The sub-cooled liquid refrigerant exits the sub-cooler, passing through the High Sierra check valve

/ TXV valve assembly, leaving the condensing unit via a bi-flow liquid filter.

The liquid refrigerant enters the evaporator, flowing through a factory mounted solenoid valve. It

passes through the expansion valve to be boiled off in the coil, providing cooling for the box. The

vaporized refrigerant returns through the suction line, the reversing valve and suction filter into the

compressor suction port.

As with any normal pump-down system, when the room temperature satisfies the thermostat, it de-

energizes the liquid line solenoid, causing the system to pump down and cycle off.

Counter flow defrost cycle

The defrost timer initiates the counter flow defrost cycle. The number of defrost cycles is set by the

installer. (The recommended frequency is one to two defrosts per day with the fail safe override set

at 10 minutes. A

normal defrost cycle lasts from 3 to 7 minutes.)

Upon the signal from the defrost timer, the reversing valve switches modes and the

evaporator fan motors are turned off. The liquid line solenoid remains energized.

The direction of refrigerant flow is now reversed, as are the functions of the evaporator and con-

denser. The reversing valve diverts the compressor discharge through, what was formerly the suc-

tion line, back towards the evaporator. A suction line check valve, (factory mounted), routes the

discharge gas through the evaporator drain pan circuit and into the coil tubes, thus providing the

heat source for the counter flow defrost.

The evaporator, now acting as the condenser, converts the discharge gas into liquid, releasing

large amounts of heat, defrosting the coil(s) very quickly.

The liquid refrigerant then exits the coil through the distributor, and the factory mounted TXV

bypass check valve. It moves through the liquid line, the bi-flow liquid filter, through the condenser

TX valve and into the system condenser (now acting as the evaporator). The liquid refrigerant is

then boiled off and returned to the compressor as suction gas, passing first through the reversing

valve and suction filter.

The defrost cycle is ended when the system pressure reaches the termination point at the defrost

control (located in the condensing unit). The inst

aller must verify that the coil clears completely of

all frost and ice. If the defrost cycle terminates before all frost has been completely removed from

the coil, the defrost termination pressure control setting may be increased incrementally until the

coil defrosts properly (maximum setting 300 psi). The recommended defrost termination setting is

250 psi with a 50 psi differential.

Diagram 5

Diagram 4

11

Counterflow defrost cycle - continued

After the refrigeration cycle resumes, the evaporator fan motors remain off during the cool

down period (never less than two minutes). This allows all condensate to drain before the

fan motors are energized, thus preventing water from blowing off the coil and into the room.

Notes:

1. The condensing unit pressure relief valve is provided to regulate potential excessive pres-

sures that may develop in the liquid line during extended shut down periods. It does not come

into play during the refrigeration or defrost cycles.

2. The condensing unit TX valve is factory set and should not be field adjusted.

3. The evaporator fan delay control is located in the condensing unit

control panel.

High Sierra Piping

Comp. Cond. Unit Rev. Valve Strainer Cond. Unit Liquid Filter Low Pres. High Pres. Fan Cycle

Type Model No. PART# PART# TXV (c.u.) PART# 230V Motor Blade Control Control Control

RHH100L44 21012 123277001 SBFSE-AA-Z 104471048 102540004 119103001 24464232 204464208 204464002

RHH165L44 21012 123277001 SBFSE-A-Z 104471049 102540004 119103001 24464232 204464208 204464002

RHH215L44 21012 123277001 SBFSE-B-Z 104471049 102540004 119103001 24464232 204464208 204464002

RHH315L44 21012 123277001 SBFSE-C-Z 104471046 102540004 119103001 24464232 204464208 204464002

RHS075L44 21012 123277001 SBFSE-AA-Z 104471048 102540004 119103001 24464232 204464208 204464002

RHS100L44 21012 123277001 SBFSE-A-Z 104471048 102540004 119103001 24464232 204464208 204464002

RHS150L44 21012 123277001 SBFSE-A-Z 104471049 102540004 119103001 24464232 204464208 204464002

RHS200L44 21012 123277001 SBFSE-B-Z 104471049 102540004 119103001 24464232 204464208 204464002

RHS250L44 21012 123277001 SBFSE-B-Z 104471046 102540004 119103001 24464232 204464208 204464002

RHS300L44 21012 123277001 SBFSE-C-Z 104471046 102540004 119103001 24464232 204464208 204464002

RHD300L44 16506 123277002 SBFSE-C-Z 104471046 201006007 213266000 24464232 204464208 204464002

RHD400L44 16506 123277002 EBSSE-6-Z 104471047 201006007 213266000 24464232 204464208 204464002

RHD500L44 16506 123277002 EBSSE-6-Z 104471047 201006007 213266000 24464232 204464208 204464002

RHO200L44 21012 123277001 SBFSE-A-Z 104471049 201006007 213266000 24464232 204464208 204464002

RHO250L44 21012 123277001 SBFSE-B-Z 104471046 201006007 213266000 24464232 204464208 204464002

RHO300L44 21012 123277001 SBFSE-B-Z 104471046 201006007 213266000 24464232 204464208 204464002

RHO301L44 21012 123277001 SBFSE-C-Z 104471046 201006007 213266000 24464232 204464208 204464002

RHO400L44 21012 123277001 SBFSE-C-Z 104471047 201006007 213266000 24464232 204464208 204464002

RHO500L44 16506 123277002 EBSSE-6-Z 104471047 201006007 213266000 24464232 204464208 204464002

RHO600L44 16506 123277002 EBSSE-6-Z 104471047 201006007 213266000 24464232 204464208 204464002

DHD5L44 21054 123277003 EBSSE-6-Z 104471047 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD6L44 21054 123277003 EBSSE-7 1/2-Z 104471047 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD8L44 21054 123277003 EBSSE-10-Z 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD9L44 21054 123277003 EBSSE-10-Z 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD10L44 21000 123277004 EBSSE-13-Z 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD12L44 21000 123277004 EBSSE-13-Z 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD15L44 21000 123277004 EBSSE-13-Z 104471193 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHO6L44 16506 123277002 EBSSE-6-Z 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHO8L44 21054 123277003 EBSSE-6-Z 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHO10L44 21054 123277003 EBSSE-10-Z 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHO13L44 21054 123277003 EBSSE-10-Z 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

VHD15L44 21049 123277005 OSE-21-Z

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD22L44 21049 123277005 OSE-21-Z

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD27L44 21055 123277005 OSE-30-Z

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD30L44 21055 123277005 OSE-30-Z

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD44L44 21055 123277005 OSE-45-Z

104471022

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD54L44 21056 Contact (2) OSE-30-Z

104471022

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD60L44 21056 Factory (2) OSE-30-Z

104471022

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

* Parts may vary based upon specific operating conditions.

† V-Series filter is not Bi-Flow Design. Part number is for replaceable core filter (shell only). Core Part# 14471034 (may require more than one core)

Discus

Discus

Scroll

Discus

Scroll

Typical High Sierra replacement parts- Low Temp. Models*

Hermetic

Semi-Hermetic

Condenser

Russell Part # Description

21065 Rebuild kit for Russell Part#16506

21066 Rebuild kit for Russell Part#21054

21067 Rebuild kit for Russell Part#21000

21068 Rebuild kit for Russell Part#21056

21070 O-Ring Kit for Russell Part# 21012

21072 O-Ring Kit for Russell Part#16506

21073 O-Ring Kit for Russell Part# 21054

21074 O-Ring Kit for Russell Part# 21000

21075 O-Ring Kit for Russell Part# 21049

21076 O-Ring Kit for Russell Part# 21055

21077 O-Ring Kit for Russell Part# 21056

21079 PILOT ASSY/MANIFOLD for Russell Part# 21054

21080 PILOT ASSY/MANIFOLD for Russell Part# 21000

21063 PILOT ASSY/MANIFOLD for Russell Part# 21049

204464020 HIGH SIERRA Defrost Termination Control

104799015 HIGH SIERRA Evap Fan Delay Control

204464004 HIGH SIERRA Condensing Unit Fan Cycle Control

104799020 HIGH SIERRA RELAYS R1 & R2 (Same number for each)

104799010 HIGH SIERRA Defrost Timer

12

Comp. Model Reversing Rev. Valve Cond. Unit Repl. Core Low Pres. High Pres.

Type Number Valve Strainer TXV Liquid Filter 230V Motor Blade Control Control

RHH075H22 21012 123277001 SBFVE-AA-C 104471048 102540004 119103001 24464232 204464208

RHH100H22 21012 123277001 SBFVE-A-C 104471048 102540004 119103001 24464232 204464208

RHH151H22 21012 123277001 SBFVE-A-C 104471049 102540004 119103001 24464232 204464208

RHH201H22 21012 123277001 SBFVE-B-C 104471049 102540004 119103001 24464232 204464208

RHH251H22 21012 123277001 SBFVE-B-C 104471046 102540004 119103001 24464232 204464208

RHH301H22 21012 123277001 SBFVE-C-C 104471046 102540004 119103001 24464232 204464208

RHH401H22 21012 123277001 SBFVE-C-C 104471047 205051004 213266000 24464232 204464208

RHH500H22 21012 123277001 SBFVE-C-C 104471047 205051004 213266000 24464232 204464208

RHH050M44 21012 123277001 SBFSE-A-C 104471048 102540004 119103001 24464232 204464208

RHH075M44 21012 123277001 SBFSE-A-C 104471048 102540004 119103001 24464232 204464208

RHH101M44 21012 123277001 SBFSE-B-C 104471048 102540004 119103001 24464232 204464208

RHH150M44 21012 123277001 SBFSE-B-C 104471049 102540004 119103001 24464232 204464208

RHH201M44 21012 123277001 SBFSE-C-C 104471049 102540004 119103001 24464232 204464208

RHH300M44 21012 123277001 SBFSE-C-C 104471046 102540004 119103001 24464232 204464208

RHH400M44 16506 123277002 EBSSE-6-C 104471047 205051004 213266000 24464232 204464208

RHS050H22 21012 123277001 SBFVE-AA-C 104471048 102540004 119103001 24464232 204464208

RHS075H22 21012 123277001 SBFVE-AA-C 104471048 102540004 119103001 24464232 204464208

RHS100H22 21012 123277001 SBFVE-A-C 104471048 102540004 119103001 24464232 204464208

RHS150H22 21012 123277001 SBFVE-A-C 104471049 102540004 119103001 24464232 204464208

RHS200H22 21012 123277001 SBFVE-B-C 104471049 102540004 119103001 24464232 204464208

RHS300H22 21012 123277001 SBFVE-C-C 104471046 102540004 119103001 24464232 204464208

RHS400H22 21012 123277001 SBFVE-C-C 104471047 205051004 213266000 24464232 204464208

RHS050M44 21012 123277001 SBFSE-A-C 104471048 102540004 119103001 24464232 204464208

RHS100M44 21012 123277001 SBFSE-A-C 104471048 102540004 119103001 24464232 204464208

RHS200M44 21012 123277001 SBFSE-B-C 104471049 102540004 119103001 24464232 204464208

RHS300M44 21012 123277001 SBFSE-C-C 104471046 102540004 119103001 24464232 204464208

RHS400M44 16506 123277002 EBSSE-6-C 104471047 205051004 213266000 24464232 204464208

RHO200M44 21012 123277001 SBFSE-C-C 104471049 205051004 213266000 24464232 204464208

RHO250M44 21012 123277001 SBFSE-C-C 104471046 205051004 213266000 24464232 204464208

RHO300M44 21012 123277001 SBFSE-C-C 104471046 205051004 213266000 24464232 204464208

RHO301M44 16506 123277002 EBSSE-6-C 104471046 205051004 213266000 24464232 204464208

RHO400M44 16506 123277002 EBSSE-6-C 104471047 205051004 213266000 24464232 204464208

RHO500M44 16506 123277002 EBSSE-6-C 104471047 205051004 213266000 24464232 204464208

RHO600M44 21054 123277003 EBSSE-6-C 104471047 205051004 213266000 24464232 204464208

RHO650M44 21000 123277004 EBSSE-7 1/2-C 104471066 205051004 213266000 24464232 204464208

* Parts selection may vary based upon specific operating conditions.

Medium Temp models are only available for warm ambient locations.

Typical High Sierra replacement parts - R-Series Medium Temp. Models*

Hermetic

Semi-Hermetic

Scroll

Condenser

13

Comp. Model Reversing Rev. Valve Cond. Unit

Bi-Flo

†

Low Pres. High Pres. Fan Cycle

Type Number Valve Strainer TXV Liquid Filter 230V Motor Blade Control Control Control

DHD5H22 16506 123277002 EBSVE-8-C 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD7H22 21054 123277003 EBSVE-11-C 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD8H22 21054 123277003 EBSVE-11-C 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD10H22 21054 123277003 EBSVE-15-C 104471193 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD12H22 21000 123277004 EBSVE-15-C 104471193 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD5M44 21054 123277003 EBSSE-10-C 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD6M44 21054 123277003 EBSSE-10-C 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD7M44 21054 123277003 EBSSE-10-C 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD8M44 21000 123277004 EBSSE-13-C 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD10M44 21000 123277004 EBSSE-13-C 104471193 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHD12M44 21049 123277005 EBSSE-13-C 104471193 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHO6M44 16506 123277002 EBSSE-7 1/2-C 104471047 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHO7M44 21054 123277003 EBSSE-10-C 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHO8M44 21054 123277003 EBSSE-10-C 104471066 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHO10M44 21000 123277004 EBSSE-13-C 104471193 205051004 213266000 204464041 Hi/Lo Combo 204464002

DHO13M44 21000 123277004 EBSSE-13-C 104471193 205051004 213266000 204464041 Hi/Lo Combo 204464002

VHD15H22 21000 123277004 EBSVE-20-C

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD20H22 21049 123277005 EBSVE-20-C

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD25H22 21049 123277005 OVE-30-C

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD30H22 21049 123277005 OVE-30-C

104471022

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD35H22 21055 123277005 OVE-40-C

104471031

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD40H22 21055 123277005 OVE-40-C

104471031

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD50H22 21055 123277005 (2) OVE-30-C

104471031

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD60H22 21056 Contact Factory (2) OVE-30-C

104471032

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD70H22 21056 Contact Factory (2) OVE-40-C

104471033

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD80H22 21057 Contact Factory (2) OVE-40-C

104471033

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD15M44 21049 123277005 OSE-21-C

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD20M44 21049 123277005 OSE-21-C

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD25M44 21055 123277005 OSE-30-C

104471021

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD30M44 21055 123277005 OSE-30-C

104471022

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD35M44 21055 123277005 OSE-30-C

104471031

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD40M44 21056 Contact Factory OSE-35-C

104471031

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD50M44 21056 Contact Factory OSE-45-C

104471031

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD60M44 21056 Contact Factory OSE-45-C

104471032

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD70M44 21057 Contact Factory (2) OSE-30-C

104471033

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

VHD80M44 21057 Contact Factory (2) OSE-35-C

104471033

†

110204000 210385000

204464041 Hi/Lo Combo 204464002

* Parts selection may vary based upon specific operating conditions.

† V-Series filter is not Bi-Flow Design. Part number is for replaceable core filter (shell only). Core Part# 14471034 (may require more than one core)

Medium Temp models are only available for warm ambient locations.

Typical High Sierra replacement parts- D-Series and V-Series Medium Temp. Models*

Discus

Scroll

Discus

Condenser

14

MODEL NUMBER ALL-TEMP²B - MODELS AA, AE (AFTER APRIL, 2004 ) PART NUM.

MOTOR, SHADED POLE, 1/20 HP, 1550 RPM, 115 V. 102540003

ALL MODELS MOTOR, SHADED POLE, 1/20 HP, 1550 RPM, 208-230 V. 102540004

MOTOR, SHADED POLE, 1/20 HP, 1550 RPM, 460 V. 102540005

ALL MODELS FAN GUARD, PLASTIC, BLACK, 12" 119647000

ALL MODELS FAN GUARD, WIRE, EPOXY COATED, BLACK, 12" 201006011

ALL MODELS MOTOR MOUNT 21062000

MOTOR, PSC, 1/20 HP, 1550 RPM, 115 V., (3 MFD CAPACITOR NOT INCL.) 108178001

ALL MODELS (OPTIONAL) MOTOR, PSC, 1/20 HP, 1550 RPM, 230 V., (2 MFD CAPACITOR NOT INCL.) 108178002

CAPACITOR, 3 MFD, FOR 1/20 115 V. PSC MOTOR 202163010

CAPACITOR, 2 MFD, FOR 1/20 230 V. PSC MOTOR 202163009

ALL "AE" MODELS DEFROST CONTROL, DEFROST TERMINATION, (TIMER RESET) 2 WIRE 103079010

ALL "AE" MODELS DEFROST CONTROL, FAN DELAY, 2 WIRE 103079009

1 - 6 FAN AE MODELS HEATER SAFETY SWITCH, 2 WIRE 103079003

AE14-37B, AE16-36B, DEFROST HEATER, CORE, 500 WATTS, 26-1/4" LENGTH, 208-230/460 V. 206240006

AE16-41B, AE16-46B DEFROST HEATER, DRAIN PAN, 500 WATTS, 21" LENGTH, 208-230/460 V. 200172042

AE24-72B, AE24-85B, DEFROST HEATER, CORE, 1000 WATTS, 44-1/4" LENGTH, 208-230/460 V. 206240008

AE26-92B DEFROST HEATER, DRAIN PAN, 1000 WATTS, 39" LENGTH, 208-230/460 V. 200172044

AE26-60B, AE26-75B DEFROST HEATER, CORE, 800 WATTS, 40-1/4" LENGTH, 208-230/460 V. 206240007

DEFROST HEATER, DRAIN PAN, 800 WATTS, 35" LENGTH, 208-230/460 V. 200172043

AE34-105B, AE36-120B, DEFROST HEATER, CORE, 1500 WATTS, 62-1/4" LENGTH, 208-230/460 V. 206240009

AE36-140B DEFROST HEATER, DRAIN PAN, 1500 WATTS, 57" LENGTH, 208-230/460 V. 200172045

AE44-140B, AE46-164B, DEFROST HEATER, CORE, 2000 WATTS, 80-1/4" LENGTH, 208-230/460 V. 206240010

AE46-185B DEFROST HEATER, DRAIN PAN, 2000 WATTS, 75" LENGTH, 208-230/460 V. 200172046

AE54-180B, AE56-210B DEFROST HEATER, CORE, 2500 WATTS, 97-3/4" LENGTH, 208-230 V. 206240011

DEFROST HEATER, DRAIN PAN, 2500 WATTS, 93" LENGTH, 208-230/460 V. 200172047

AE64-215B, AE66-245B, DEFROST HEATER, CORE, 3000 WATTS, 115-3/4" LENGTH, 208-230/460 V. 206240012

AE66-280B DEFROST HEATER, DRAIN PAN, 3000 WATTS, 111" LENGTH, 208-230/460 V. 200172048

1 FAN AA, & AE MODELS VENTURI, 20" LENGTH 8519104

AA28-76B, -97B, -122B,

AA26-70B, -87B, AE26-60B, VENTURI, 34" LENGTH 8519241

AE26-75B

AA28-106B, -134B, AA26-115B VENTURI, 38" LENGTH 8519242

AE26-92B, AE24-85B

3 FAN AA & AE MODELS VENTURI, 56" LENGTH 8519243

4 FAN AA & AE MODELS* VENTURI, 74" LENGTH 8519244

5 FAN AA & AE MODELS* VENTURI, 92" LENGTH 8519245

6 FAN AA & AE MODELS* VENTURI, 110" LENGTH 8519246

1 FAN AA, & AE MODELS DRAIN PAN, 27" LENGTH 8519592

AA28-76B, -97B, -122B,

AA26-70B, -87B, AE26-60B, DRAIN PAN, 41" LENGTH 8519593

AE26-75B

AA28-106B, -134B, AA26-115B DRAIN PAN, 45" LENGTH 8519594

AE26-92B, AE24-85B

3 FAN AA & AE MODELS DRAIN PAN, 63" LENGTH 8519595

4 FAN AA & AE MODELS* DRAIN PAN, 81" LENGTH 8519596

5 FAN AA & AE MODELS* DRAIN PAN, 99" LENGTH 8519597

6 FAN AA & AE MODELS* DRAIN PAN, 117" LENGTH 8519598

SHORT

HINGED END PANEL

8518612

LONG

HINGED END PANEL

8518613

ACF Model 1 Fan Evaps

Hot Gas Drain Pan Assembly w/ loop 12297800

ACF Model 2 Fan (Short) Evaps Hot Gas Drain Pan Assembly w/ loop 12297900

ACF Model 2 Fan (Long) Evaps

Hot Gas Drain Pan Assembly w/ loop 12298000

ACF Model 3 Fan Evaps Hot Gas Drain Pan Assembly w/ loop 12298100

ACF Model 4 Fan Evaps

Hot Gas Drain Pan Assembly w/ loop 12298200

ACF Model 5 Fan Evaps Hot Gas Drain Pan Assembly w/ loop 12298300

ALL-TEMP²B - HINGED END PANEL UNITS (AFTER APRIL, 2004 )

15

High Sierra Systems

Additional Service, Installation and Trouble Shooting Tips

In the event of freezing drain pan Problems: Check the following

1. Verify that the unit cooler has been installed in a way insuring the drain pan is slightly pitched towards the drain

connection. This will provide positive drainage of the condensate.

2. The surface of the drain pan must

be touching the Hot Gas drain pan tubes, located in the bottom of the unit

cooler. Later model units have the drain pan loops welded to the drain pan.

3. The High Sierra system has a time initiated and pressure terminated defrost. The pressure switch is factory set

at 250# Cut In pressure and 200# Cut Out pressure. If the 250 pound setting does not clear the coil, the

setting may be raised to a higher pressure, but no higher than 300 pounds (use high pressure gauge for

this check). The time clock should have a maximum

of (3) three defrosts per 24 hours. (We suggest the clock

be set for 1 to 2 defrosts per 24 hours). The time clock fail safe should be set at 10 minutes maximum. 1 to 2

defrosts per 24 hours will ensure a longer defrost, 3-5 minutes in length.

4. The evaporator fans should have a two minute delay after defrost. This control is located in the condensing unit

control panel. If the delay setting is less than two minutes, it should be corrected.

5. Check drain pan for straightness, if warped, the pan may have to be replaced.

6. Check the Hot Gas Loop, it should be straight and must make contact with the drain pan.

7. Evaporator Drain lines must be installed with copper tubing, wrapped with heat tape, insulated and trapped. The

trap should be located outside of the freezer.

8. Superheat setting must be checked, 8°F @ coil, 20°F to 40°F at the compressor.

9. Refrigerant charge, charge to clear sight glass after room is within 10° of desired temperature.

DO

NOT OVER CHARGE.

10. Check the expansion valve bulb on the outdoor unit, it must be clamped tightly in the proper location.

11. Fan Cycling control, Fan on at 90 psi. off at 60 psi.

Russell High Sierra System Data Sheet

Date: ____________ Contractor: ______________________________

High Sierra C.U. Model #_____________________ Serial # ____________________

Evaporator Coil Model #______________________ Serial # ____________________

1. Discharge pressure before defrost _________lbs. After defrost _______________ lbs.

2. Suction pressure before defrost _________ lbs. After defrost _______________ lbs.

3. Superheat @ Coil before defrost _________ °F After defrost_______________°F

4. Compressor Superheat before defrost _________°F After defrost_______________°F

5. Sight glass condition before _________ after defrost___________ (clear or bubbles)

6. Suction Temperature reading across reversing valve IN__________ OUT__________

7. How long did the defrost last _____ Time clock fail safe setting ______

8. What was the defrost termination pressure ___________ lbs.

9. How many defrosts per day__________

10.Coil condition after defrost _____________________________

11. Condenser fan cycling control: Cut in ________ Cut Out ________

12. Fan Delay setting (should be no less than 2 minutes in duration) _____________

221 S. BERRY ST. BREA, CA. 92822-1030 TEL. (714) 529-1935 FAX (714) 529-7203

www.russellcoil.com

pn: 122300059