THAILAND

DATA COLLECTION SURVEY

ON

INFRASTRUCTURE MANAGEMENT

IN

THAILAND

FINAL REPORT

December 2014

JAPAN INTERNATIONAL COOPERATION AGENCY

(

JICA

)

KOKUSAI KOGYO CO.,LTD.

1R

JR

14-065

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

- 1 -

Summary

1. Outline of the Survey

Background

In Japan, many infrastructure facilities have already aged and many more will have aged in the

near future, therefore infrastructure facility management to appropriately maintain and repair

facilities, extending their life periods while giving due consideration to budgetary constraints,

has recently been given deep and widespread attention.

In Thailand, aging of infrastructure facilities will become a serious concern in a decade or two.

Moreover, Thailand is still promoting new infrastructure construction to keep up its economic

competence with the world, which means Thailand may need to take care of both aging

infrastructure facilities and new construction simultaneously.

Definition of Infrastructure Management

In this study ‘Infrastructure Management’ is defined as methods and methodologies to

comprehensively plan, manage and operate civil infrastructure systems. Sometimes the term

‘asset management’ is used in similar situations. This term means economically and

technically rational maintenance plans for each facility and equipment and methodologies for

their implementation.

Relationship between infrastructure management, asset management, and engineering

maintenance management for individual facilities is illustrated in the following figure.

( ): examples

Figure: Infrastructure Management System

Objectives

1) Introduce the idea of infrastructure facility management, which can extend life periods

of infrastructure facilities by managing their routine preventive care and maintenance.

2) Introduce Japanese technologies and skills for infrastructure facility management.

Infrastructure Management

Asset

Management

(Water Supply Sector)

Maintenance

management

(Pipelines)

Maintenance

management

(Purification

facilities)

Maintenance

management

(Pumping

stations)

Asset

Management

(Road Sector)

Maintenance

management

(Pavement)

Maintenance

management

(Bridges)

Maintenance

management

(Safety facilities)

Asset

Management

(Railway Sector)

Maintenance

management

(Civil

engineering)

Maintenance

management

(Telecommunication)

Maintenance

management

(Trains)

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

- 2 -

3) Examine possibilities of Japan’s support using Official Development Assistance

and/or application of technologies and expertise from Japanese companies.

Work Period

This survey started in June 2014 and was completed in November 2014. The team executed

two surveys in Thailand during this period.

2. Efforts for Infrastructure Management in Japan

In Japan, the authorities competent in the target sectors in this survey are the Ministry of Land,

Infrastructure, Transport and Tourism for the road, railway and sewerage sectors, the Ministry

of Health, Labor and Welfare for the waterworks sector and the Agency for Natural Resources

and Energy, an extra-ministerial bureau of the Ministry of Economy, Trade and Industry for the

electricity sector.

As the implementing organizations in the railway and electricity sectors are private companies,

each of them is taking its own measures against deterioration of infrastructure. The roles of

the competent authorities in these sectors are limited to preparation of laws and standards and

supervision of the service providers.

Since introduction and development of asset management forms the foundations for

infrastructure management, efforts for asset management were explained first.

In the waterworks sector, in June 2004, the Ministry of Health, Labor and Welfare (MHLW)

developed the Water Supply Vision, which collectively indicates policy priorities concerning

the water supply system in the future, and in July 2008 the introduction of the asset management

method was added as a priority issue. Following the publication of the New Water Supply

Vision, the MHLW has recommended water service providers and prefectural governments to

prepare specific plans since March 2014 to clearly define their scopes of works and encourage

them to take measures compliant with the new vision. The similar efforts have been executed

in the sewerage sector as well.

The Minister of Land, Infrastructure, Transportation and Tourism (MLIT) began to take

practical measures to facilitate extension of life of infrastructure facilities as measures against

its deterioration in 2006. While the ministry was taking such measures, the ceiling boards in

the Sasago Tunnel collapsed in December 2012. This accident led to spread of the awareness

of the necessity of measures against the deterioration of infrastructure in the Japanese society

and of the necessity of implementation of comprehensive countermeasures. In November

2013, the Minister of Land, Infrastructure, Transportation and Tourism set up the “Basic Plan to

Extend Life of Infrastructure Facilities” to develop measures to control the aging of the

infrastructures of the government as a whole.

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

- 3 -

Figure: System of Basic Plan to Extend Life of Infrastructure Facilities

In order to extend the life of all infrastructure facilities across the country, this basic plan

presents directives for authorities responsible for the infrastructure to implement collective and

planned infrastructure management under the initiative of the MLIT. MLIT compiled the

measures to be taken for seven years up to 2020 in an Action Plan. Local governments have

begun the preparation of comprehensive public facility management plans.

As an example of a local government, the Fuchu city presented a policy for the infrastructure

management in future based on the result of the study in The Fuchu City Infrastructure

Management Plan, which was published in January 2013. In the plan, the city estimates the

cost-reduction realized by implementing all the measures in the plan at 12%.

New technologies in Japan include: a camera system for inspection used where visual

inspections are not possible, materials to improve durability of road pavements and their ability

to disperse water, and repair methods for pipeline without having to disrupt water supply.

As for international trends, the ISO55000 series are international standards that provide

guidelines for the implementation of asset management by organizations that own and manage

assets in compliance with the stipulated requirements. This series came into force in January

2014.

3. Compare Infrastructure Management Approaches in Developed Countries and

Assess Comparative Advantages of the Japanese Approaches

In the U.S.A., since “Crumbling America” representing the situation in the 1980’s, they have

started to introduce asset management for infrastructure facilities by strengthening financial

capacities and institutional systems. There are no laws or regulations that make asset

management or infrastructure management a requirement. The U.S.A. has a federal system,

meaning that the federal government concentrates on improvement of financial sources,

institutional systems, development of databases for maintenance, investment optimization

systems and so on; meanwhile each state is responsible for implementation of PDCA and so on.

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

- 4 -

There are different competent authorities for each sector, unlike Japan where MLIT is

competent in more than 10 sectors. Therefore, federal and state governments do not develop a

cross sectoral holistic policies or plans, nor do they enforce the implementation of such plans.

In Europe, private sector participation has been encouraged since long ago and the central

governments execute the promotion and supervision of private sector participation by using

institutional arrangements. Central governments often adopt the concession contract for the

work which can be expected to be able to recoup costs through tolls/fees, and also PFI by

paying a contractor a fee calculated by shadow toll fee system.

Regarding individual technologies, Japan has a comparative advantageous over the U.S.A. and

U.K. in terms of skills for safe work on roads, which are often narrow and leading to intricate

alleyways, and in terms of durable materials in a climate with large annual temperature

variations and many natural disasters such as typhoons and earthquakes.

Therefore, the advantages of Japan over the Western countries are found in the national-level

planning of comprehensive infrastructure management, systems and methods for providing

assistance to infrastructure administrators in planning, initiatives of municipalities in the

waterworks and sewerage, technologies for working in narrow and intricate roads, and material

technologies in consideration of earthquake resistance and disaster prevention functions.

4. Current Status of Infrastructure Management in Thailand

In the transport and communications sector, investment in new communications infrastructure is

apparent in recent years, while some of transportation infrastructure is getting older. The

situation is similar in the railway sector, where 67% of railways of State Railway of Thailand

are more than 30 years old. For example, aging of bridges is evident: among the bridges

managed by Department of Highways, there are now 338 bridges which are more than 50 years

old, or 2% of the total, and this figure will be 1,818 or 12% in another 10 years.

On the other hand, Thailand is planning to develop new infrastructure facilities in view of the

formation of ASEAN Economic Community in 2015. In 2013, the government announced a

large-scale infrastructure development plan up to 2020 whose total cost amounts to more than 2

trillion baht.

In Thailand, the ratio of senior citizens 65 years of age or older exceeded 7% in 2007, which

means the arrival of an “aging society,” and will reach 14% in 2027 when Thailand will become

a “super-aging society”. Therefore, it will inevitably be difficult in the future to acquire fund

sources for infrastructure improvement.

In Thailand, the demand for construction will continue even after the start of a phase of

maintenance and replacement of infrastructure facilities. Thailand will need to implement both

of them at the same time, therefore it has to devise ways to further improve the efficiency of

constructing and maintaining infrastructure facilities.

The statuses of sectors are recognized as follows by NESDB, which is influential on

infrastructure management through assessment of each organization’s plan and policy:

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

- 5 -

For the road sector, maintenance will be emphasized as more priority is placed on railways.

For the railway sector, priority will be placed on new investment to enhance the railway

network.

The waterworks sector has no problem in Metropolitan Water Authority (MWA) and

Provincial Water Authority (PWA) coverage areas with good conditions. However, PWA

has large water supply areas with regional differences so that an adequate level of service

has not reached remote, sparsely populated areas.

The sewerage sector has a problem of not being able to charge for the services.

The power sector has a good financial state and is free of maintenance problems.

5. Case Study on Infrastructure Management in Priority Sectors

Holistic infrastructure management across these sectors should be based on national

government’s plans leading to specific actions. The role of national governments in Thailand,

however, is to make policies and it is implementing organizations that make plans based on the

policies. As such, the planning and budgeting organizations are not aware of nor ready for

their responsibility in infrastructure management. It is difficult to develop measures whose

effect can be confirmed within the scope of this study. Therefore, the Study Team selected

priority sectors which are ready for asset management and developed measures for target

organizations which could cooperate with this study. This process also intended to promote

better understanding of infrastructure management

The waterworks sector and the road sector were selected as priority sectors based on the

assessment result of each sector because the infrastructure management in these sectors in

particular is becoming very important. MWA for the waterworks sector and EXAT for the

road sector were selected as target organizations for case studies because both the management

priority in both organizations is shifting from the new construction to the maintenance and the

basic organizational system to implement infrastructure management has been mostly arranged.

In order to present effective examples to clearly show to each infrastructure management

organization the countermeasures within the capacity of this case study, the case study focuses

on long-term perspectives on a few important issues to examine countermeasures, taking

various circumstances and conditions for the organization into account. In addition, an

examination on the effects of revising road design standards is executed because such a revision

was very effective in Japan. These three case studies with different patterns were executed to

examine countermeasures.

1) Case to Examine Countermeasures to Improve Efficiency of Water Supply Business

This case study focuses on the Metropolitan Water Authority and the feasibility of it utilizing

Life-Cycle Cost (LCC) analysis for selecting new pipe types for replacement. The study also

investigates the most cost effective combination of pipe types in terms of reduction of

non-revenue water ratio and water production costs. The study compares two scenarios of

possible countermeasure, and found that the maintenance cost can be reduced by more than 51

bill baht over the next 50 years.

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

- 6 -

Table: Cost Benefit Ratio and O & M Cost Ratio for Scenarios

Unit: Mill baht/50 years

Scenario

Accumulated operation and

maintenance (O& M) costs Difference

from BS

Cost savings

from BS (%)

Accumulated

O &M

costs/Revenue

(%)

Pipe Pump Total

Baseline

Scenario (BS)

188,105 73,803 261,908 - - 20.8%

Scenario 1 142,763 67,612 210,375 -51,533 20.0% 19.2%

Scenario 2 140,994 66,266 207,260 -54,648 20.9% 18.9%

Note: The accumulated revenue over 50 years is estimated as 1,097,144 million baht.

2) Case to Examine the Countermeasures to Cope With the Deterioration of Concrete

Structures Due to Aging

This case study focuses RC slab of elevated road of Expressway Authority of Thailand

(EXAT) to minimize the required maintenance budget, which is expected to greatly increase in

future due to aging of concrete structures. It examines alternative measures using LCC analysis

to identify the optimum maintenance method. The study compares the total maintenance costs

for 100 years, and found that it is 75 million baht by corrective maintenance and 34 mill baht by

preventive maintenance, and thus the preventive maintenance reduces the total cost by 55%.

Table: Result of Case Study

Accumulated maintenance cost for 100 years (bill baht)

Cost difference

Corrective maintenance

scenario

Preventive maintenance

scenario

Case 1

75

45 40%

Case 2 34 55%

3) Case to Examine the Impact on LCC of Road Pavement by Doubling the Design

Useful Years

In Japan, the revision of road pavement design standard in 2001 was one of the factors that

helped promote the uptake of long life road pavements to reduce LCC. This case Study

examines the impact on LCC of road pavements if such a road pavement design standard

revision is undertaken in Thailand. It compares the LCC of road based on the present design

standard with 15 year service life and LCC of road based on the 30 year service life design

standard. The case Study found that LCC of road pavement can be reduced by 32% based on

100 years.

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

- 7 -

6. Technical Transfer

A workshop and a seminar were held during the survey period.

Workshop

For the purpose of explaining study objectives and introducing the approaches toward

infrastructure management in Japan, a workshop was held on July 16th with the attendance of

invitees from target organizations. There were 59 participants from 16 target organizations

and one university, and this implied the high need for technical improvement of infrastructure

management.

The answers to the questionnaires revealed that the workshop enhanced the awareness of

infrastructure management with a focus on preventive maintenance and that there were needs

among the participants for Japanese technology and knowledge for all the aspects of

infrastructure management.

Seminar

For the purpose of explaining the results of the study and suggestions regarding infrastructure

management, a seminar was held on October 21st with the attendance of invitees from target

organizations. There were 60 participants from 17 target organizations and one university.

The Study Team presented the infrastructure management situations and three case studies to

show the effect of life extension measures using LCC in water and road sectors. There was a

presentation from a professor in Chulalongkorn University about ISO55000.

As the summary of this seminar, we pointed out keys to implementing infrastructure

management found through this study. The questionnaire asked how important the participants

consider each key message. Participants understood the importance of all messages, especially

importance of infrastructure management and use of LCC for procurement were understood

well.

Participants from implementation organizations recognize laws and rules, policy, and budget as

obstacles. Other issues mentioned are that it is difficult to convince budget bureau and

executives and especially because they do not have proven performance to convince, and that

structural separation between planning and maintenance makes it difficult to share information.

7. Findings from the Survey

(1) Financial source

SEPO is active to introduce the private fund such as PPP scheme and infrastructure fund

for the development and operation of infrastructure which the profit can be expected.

Securing funding is essential to continue steady maintenance of existing infrastructure

facilities. It is an effective way to create taxes and subsidies preferentially allocated for

maintenance activities in Thailand.

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

- 8 -

(2) Management policy and needs

1) Creation of Framework for Infrastructure Management

In Thailand there is a continuing demand for new infrastructure construction and infrastructure

facilities are increasing and aging at the same time. Under such a circumstance, how to

support budget for new investment and maintenance at the same time is a pressing issue for the

Thai government. The following are suggested as solutions.

1) For new construction, consider measures to minimize LCC from design, procurement

through to the end of use.

2) For maintenance of existing infrastructure facilities, consider LCC and implement

measures against aging and for life extension

To promote proactive engagement in this policy to implementing organizations, it is effective

that national competent authorities set a holistic policy for implementing organizations at

national and local levels to consider all infrastructure facilities including both new and existing

infrastructure facilities.

2) Approaches to State Owned Enterprises

In order to urge state owned enterprises to promote asset management, SEPO which is

responsible for supervising all state enterprises in Thailand should emphasize infrastructure

management in a Statement of Directions.

(3) Management plan and measures

1) Integrated management is essential for successful infrastructure management and

organization structures enabling cross-sectional and comprehensive consideration and

decision making works well.

2) Reduction of LCC by life extension is an important method and it is effective to

proactively promote research on life extension technology and data accumulation on a

trial basis.

3) Understanding of the current situation of RC structures is urgent, therefore, inspection

work and the preparation of inspection database of all facilities should be completed as

soon as possible.

4) The case study showed the advantages of consideration of LCC in selection of several

technologies and materials and of planning a long-term strategy based on cost

estimation for longer than the service lives of materials and equipment. In addition,

it is effective to proactively find and use new and better materials.

(4) Organization structure and skills

1) The revision of design standards of pavement should be actively examined.

2) DOH and DRR offer staff training on maintenance including practical works and LCC

methods. It is useful and should be continued.

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

- 9 -

3) Procurement costs can be saved drastically if PWA headquarters establish joint

procurement systems for all 234 branches.

(5) Support from Japan

1) An effective technical training for Thailand should cover practical skills of inspection

and maintenance, analysis such as LCC and projection of deterioration curve, and

infrastructure management method.

2) Because the implementation level of inspection and maintenance in Thailand is

assessed as being quite high, the technologies in Japan which can meet the needs are

only very advanced ones.

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

i

Table of Contents

1 Outline of the Survey ............................................................ 1

Background ................................................................................................................... 1

Definition of Infrastructure Management ..................................................................... 1

Objectives ..................................................................................................................... 1

Scope ............................................................................................................................. 2

Implementation Structure .............................................................................................. 4

Study Team Members ................................................................................................... 9

2 Efforts for Infrastructure Management in Japan ................. 10

Efforts of Central Government ................................................................................... 10

Efforts of Local Governments .................................................................................... 28

New Technologies ...................................................................................................... 36

Commitments by Academic Societies and Industry ................................................... 60

Trend in the Methods for Infrastructure Facility Management ................................... 64

3 Compare Infrastructure Management Approaches in

Developed Countries and Assess Comparative Advantages of

the Japanese Approaches .................................................. 70

Current Situation of Aging Infrastructure Facilities in the U.S.A. and Europe .......... 70

Approaches Taken by the Governments in the U.S.A. and Europe ............................ 79

Infrastructure Management Initiatives in the U.S.A. and Europe ............................... 87

New Technologies in the U.S.A. and Europe ............................................................. 98

Comparative Advantages of Japan Compared with the U.S.A. and Europe ............. 103

4 Current Status of Infrastructure Management in Thailand 106

Status of Aging Infrastructure and Future Forecast .................................................. 106

Current Status of the National Government .............................................................. 110

Current Status of the Bangkok Metropolitan Administration (BMA) ...................... 121

Road Sector ............................................................................................................... 124

Water Supply Sector ................................................................................................. 186

Sewerage Sector ........................................................................................................ 205

Railway Sector .......................................................................................................... 210

Electricity Sector ....................................................................................................... 221

Evaluation Summary ................................................................................................. 236

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

ii

5 Case Study on Infrastructure Management ...................... 243

Selection of Target Organizations ............................................................................ 243

Selection of Case Studies in the Priority Sectors ...................................................... 245

Case to Examine Countermeasures to Improve Efficiency of Water Supply Business248

Case to Examine the Countermeasures to Cope With The Deterioration of Concrete

Structures Due To Aging .......................................................................................... 269

Case to Examine the Impact to LCC of Road Pavement by Doubling the Design Useful

Years ......................................................................................................................... 281

6 Technical Transfer ............................................................ 286

Workshop .................................................................................................................. 286

Seminar ..................................................................................................................... 292

7 Findings from the Survey .................................................. 297

Financial Source ....................................................................................................... 297

Management policy and needs .................................................................................. 297

Management plan and measures ............................................................................... 299

Organization structure and skills .............................................................................. 300

Support from Japan ................................................................................................... 301

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

iii

Figures

Figure 1 Proportion of Bridges by Decade of Construction in OECD Member Countries .. 11

Figure 2 Change in the Number of Road Bridges (15 m or longer) Used for More or Less than

50 Years in Japan (1991-2051) ....................................................................................... 11

Figure 3 Changes in the Total Length of Water Supply Pipelines and the Proportion of Pipes

Installed at Least 40 Years Ago ...................................................................................... 12

Figure 4 Accidents Caused by Deterioration of a Bridge (above left), a Railway (above right),

a Tunnel (below left) and a Water Supply Pipe (below right) ........................................ 13

Figure 5 Trends of Social Security Expenses and Public Works Expenses ......................... 14

Figure 6 Image of Maintenance Cost Equalization .............................................................. 15

Figure 7 Infrastructure Management System ....................................................................... 16

Figure 8 Asset Management Practice Cycle......................................................................... 18

Figure 9 Feedback to the Reinforcement of the Foundation of Operation and the Regional

Waterworks Vision ......................................................................................................... 19

Figure 10 Trends of Length of Pipelines Constructed Each Year and Incidence of Road

Subsidence ...................................................................................................................... 21

Figure 11 Composition of New Sewerage Vision ................................................................ 23

Figure 12 System of Basic Plan to Extend Life of Infrastructure Facilities Promoted by MLIT

........................................................................................................................................ 25

Figure 13 Image of Promotion of Measures to Control Aging Based on Comprehensive Public

Facility Management Plan .............................................................................................. 29

Figure 14 Difference in Annual Infrastructure Management Cost between As-is and Planned

(Predicted) ...................................................................................................................... 31

Figure 15 Description of Pilot Project Concerning Comprehensive Outsourcing ............... 32

Figure 16 Operations of Advanced Business Service Co., Ltd. ........................................... 34

Figure 17 Operations Packaged in the Project ..................................................................... 35

Figure 18 Power Distribution Facilities Cost Equalization Concept .................................... 62

Figure 19 Power Industry Asset Management Activities ..................................................... 63

Figure 20 Engineering Management Cycle .......................................................................... 65

Figure 21 Engineering and Economic Management Cycle .................................................. 66

Figure 22 Relationships between Components of the Asset Management System and the

Requirements in Each Component ................................................................................. 68

Figure 23 Scenes of the Collapse of the Silver Bridge ......................................................... 71

Figure 24 Scenes of the Collapse of the Lakeview Drive Bridge ........................................ 71

Figure 25 Scene of the Collapse of the Highway Bridge in Minneapolis ............................ 72

Figure 26 Road Caved in due to the Water Main Break (January 15, 2014) ....................... 72

Figure 27 Night view during the Northeast Blackout of 2003 (Left: Normal, Right: Blackout)

........................................................................................................................................ 73

Figure 28 Transition of Infrastructure Evaluations by ASCE .............................................. 74

Figure 29 Gap between Future Prospects and Budgets for Maintenance and Replacement in

U.S.A. ............................................................................................................................. 74

Figure 30 Collapse of a Bridge Caused by Breaks of Pre-stressing Steel Bars.................... 75

Figure 31 Overall Evaluation of Infrastructure Facilities in the U.K. .................................. 78

Figure 32 Cost for Infrastructure Improvement in the U.K.................................................. 78

Figure 33 Change in Gas Tax and Its Usage in the U.S.A ................................................... 80

Figure 34 Repair Costs of Major Bridges in City of NY (1981-2002) ................................ 81

Figure 35 FHWA Organization Chart .................................................................................. 82

Figure 36 Road Map of Transportation Asset Management Guide: A Focus on Implementation

........................................................................................................................................ 83

Figure 37 Percentage of Pipes that were Installed 100 Years Ago or More ........................ 87

Figure 38 Major Concession Toll Roads in U.S.A ............................................................... 88

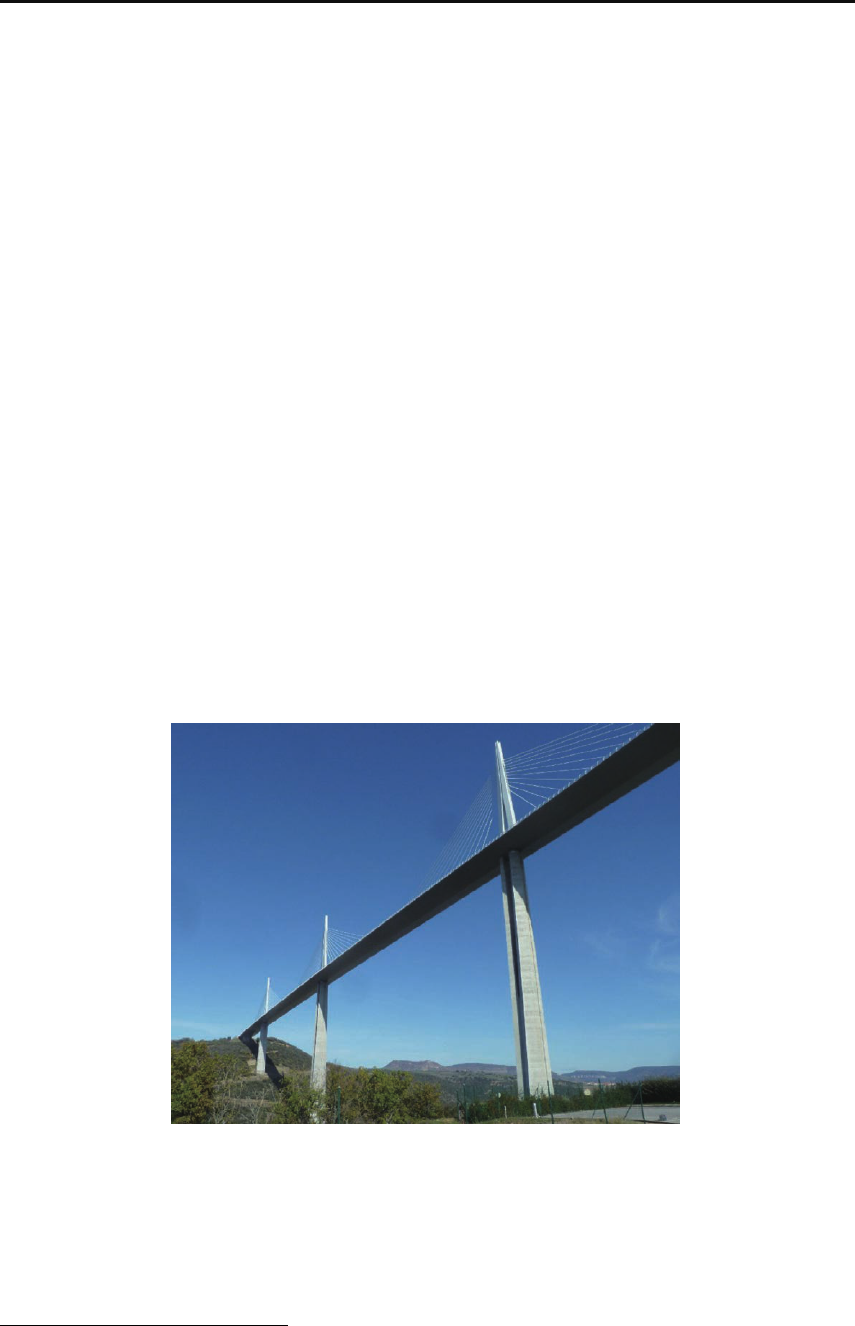

Figure 39 Millau Viaduct ..................................................................................................... 95

Figure 40 Architectural Framework of BRIME ................................................................... 97

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

iv

Figure 41 Trends of Net Social Capital in Public Sector (current prices) .......................... 106

Figure 42 Number of Bridges by Age ................................................................................ 107

Figure 43 Demographic Statistics of Thailand (1950 – 2050) ........................................... 108

Figure 44 Project Application and Review Scheme ........................................................... 112

Figure 45 Application for Annual Budget and Review Scheme ........................................ 113

Figure 46 Roads in Thailand .............................................................................................. 125

Figure 47 Organization Chart of DOH ............................................................................... 128

Figure 48 Trend of DOH Budget for New Construction and Maintenance & Repair ........ 129

Figure 49 Classification Guideline for the Maintenance Budge ........................................ 131

Figure 50 Budget Proposal and Approval Stream within DOH ......................................... 132

Figure 51 Inspection and Evaluation Sheet ........................................................................ 133

Figure 52 Hawk Eyes Produced by ARRP Company ........................................................ 134

Figure 53 Maintenance Manual and Inspection Sheet ....................................................... 137

Figure 54 Structure of Road Maintenance Management System ....................................... 138

Figure 55 Screen Shot of Road Maintenance and Management System ............................ 139

Figure 56 Number of Bridges by Age Category as of Feb. 2014 ....................................... 140

Figure 57 Classification of Bridges used by DOH ............................................................. 140

Figure 58 Number of Bridges by Type .............................................................................. 141

Figure 59 Workflow of Budget Approval for Bridges ....................................................... 144

Figure 60 Organization Chart of DRR ............................................................................... 146

Figure 61 Image of Benkelman Beam Test ........................................................................ 148

Figure 62 Rosy Car ............................................................................................................ 149

Figure 63 Map of Expressways Managed by EXAT ......................................................... 154

Figure 64 Classification of EXAT Expressways by Service Years ................................... 155

Figure 65 EXAT Organization Chart (Source: EXAT Annual Report 2013)

...................................................................................................................................... 157

Figure 66 Tools Used for Daily Inspection ........................................................................ 161

Figure 67 Yearly Inspection Schedule ............................................................................... 162

Figure 68 Tools Used for Special Inspection ..................................................................... 163

Figure 69 Inspection of Foundations of Viaduct ................................................................ 163

Figure 70 Elevation Plan of Rama IX Bridge .................................................................... 167

Figure 71 Organization Chart of Public Works Department of BMA ............................... 170

Figure 72 Bridge Site Location Shown in the Database .................................................... 171

Figure 73 Basic Information of Bridge Shown in the Database ......................................... 172

Figure 74 Site Photos of Damage Shown in the Database ................................................. 172

Figure 75 Example of Bridge Inspection Report ................................................................ 173

Figure 76 Diagnosis Record of Bridge ............................................................................... 174

Figure 77 Inspection Data of Super-structure .................................................................... 181

Figure 78 Inspection Data of Super Structure Before and After Repair ............................ 184

Figure 79 Service Area of MWA ....................................................................................... 186

Figure 80 Previous Management Tool ............................................................................... 193

Figure 81 Linking Pipeline Facility Maps with As-built Drawings ................................... 193

Figure 82 GIS Usage in MWA ........................................................................................... 194

Figure 83 Before and After Repair of Filter Basin ............................................................. 196

Figure 84 Water Leakage in Water Purification Facility ................................................... 196

Figure 85 Flow Rate in Distribution Pipe .......................................................................... 202

Figure 86 Repair History of Pipelines ................................................................................ 203

Figure 87 Hydrological Accounting (Rangsit Branch) ...................................................... 203

Figure 88 DSD Organization Chart .................................................................................... 206

Figure 89 SRT Trunk Railway Lines ................................................................................. 211

Figure 90 SRT Organization Chart .................................................................................... 212

Figure 91 Trend of Number of Passengers of MRT Blue Line .......................................... 216

Figure 92 MRTA Organization Chart ................................................................................ 217

Figure 93 BMCL Organization Chart for Engineering and Maintenance Group ............... 217

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

v

Figure 94 BMCL’s Asset Management Strategy ............................................................... 219

Figure 95 BMCL’s Asset Management for Contractors .................................................... 220

Figure 96 Structure of Electricity Market in Thailand ....................................................... 221

Figure 97 EGAT Organization Chart ................................................................................. 223

Figure 98 MEA Trend of Power Consumption .................................................................. 227

Figure 99 MEA Trend of Number of End Users ................................................................ 227

Figure 100 MEA Organization Chart ................................................................................. 228

Figure 101 PEA Organization Chart .................................................................................. 232

Figure 102 PEA’s Basic Concept of Asset Management ................................................... 233

Figure 103 Focus in Long, Mid, and Short-Term Asset Management Plan ....................... 234

Figure 104 Present Condition of Each Sector in terms of Management of Infrastructure

Facilities ....................................................................................................................... 245

Figure 105 Length of AC Pipe and PVC Pipe by Year to be Replaced ............................. 249

Figure 106 Changes in NRW, Total Water Consumption and Ratio of NRW ................... 250

Figure 107 Changes in Population in the Water Supply Area ........................................... 251

Figure 108 Basic Policy of the Case Study ........................................................................ 252

Figure 109 Change in Operation and Maintenance Costs: Baseline Scenario ................... 260

Figure 110 Change in NRW Rate: Baseline Scenario ........................................................ 260

Figure 111 Change in Operation and Maintenance Costs: Scenario 1 ............................... 261

Figure 112 Change in NRW Rate: Scenario 1 ................................................................... 261

Figure 113 Change in Operation and Maintenance Costs: Scenario 2 ............................... 262

Figure 114 Change in NRW Rate: Scenario 2 ................................................................... 262

Figure 115 Accumulated Operation and Maintenance Costs for 3 Scenarios .................... 263

Figure 116 Change of NRW Rate and NRW for 3 Scenarios ............................................ 263

Figure 117 Operation and Maintenance Costs of Pumps: Baseline Scenario .................... 264

Figure 118 Operation and Maintenance Costs of Pumps: Scenario 1 ................................ 265

Figure 119 Operation and Maintenance Costs of Pumps: Scenario 2 ................................ 265

Figure 120 Operation and Maintenance Cost of Pumps: 3 Scenarios ................................ 266

Figure 121 Accumulated Operation and Maintenance Costs including Pumps for 3 Scenarios

...................................................................................................................................... 267

Figure 122 Classification of EXAT Expressway by Service Years ................................... 270

Figure 123 An Example of Deterioration of RC Slab ........................................................ 271

Figure 124 Image of Deterioration Curve of Concrete Structure ....................................... 272

Figure 125 Image of Performance Curves by Scenario ..................................................... 273

Figure 126 Accumulated maintenance cost (LCC) of RC slab by corrective maintenance for

Din Daeng Expressway ................................................................................................ 274

Figure 127 Accumulated maintenance cost (LCC) of RC slab by corrective maintenance for

all expressways ............................................................................................................. 274

Figure 128 Image of thickening RC slab method ............................................................... 275

Figure 129 Pictures of implementation of thickening RC slab method ............................. 275

Figure 130 Accumulated maintenance cost of RC (LCC) slab for Din Daeng Expressway in

Case 1 ........................................................................................................................... 277

Figure 131 Accumulated maintenance cost (LCC) of RC slab for all expressways in Case 1

...................................................................................................................................... 278

Figure 132 Accumulated maintenance cost (LCC) of RC slab for Din Daeng expressway in

Case 2 ........................................................................................................................... 279

Figure 133 Accumulated maintenance cost (LCC) of RC slab for all expressway in Case 2279

Figure 134 Length of Highway of DOH ............................................................................ 281

Figure 135 Estimated LCC of Road Pavement by Different Design Useful Life .............. 284

Figure 136 Interesting Topics by Sector (multiple answers allowed) ................................ 290

Figure 137 Recognition of Importance by Key Message ................................................... 295

Figure 138 Issues in Infrastructure Management in Thailand ............................................ 298

Figure 139 Government-led Plan to Extend Life of Infrastructure Facilities .................... 298

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

vi

Tables

Table 1 Target Areas and Facilities ........................................................................................ 3

Table 2 Contents of the Initial Study ..................................................................................... 4

Table 3 Queries based on PDCA to Administrative Organizations in Thailand .................... 6

Table 4 Schedule of Visit for Interview ................................................................................. 7

Table 5 Possible Recommendations of Measures to be Taken (Tentative) ............................ 8

Table 6 2

nd

Study Schedule .................................................................................................... 9

Table 7 Measures Relative to Infrastructure Management Taken by MLIT and MIC in Recent

Years ............................................................................................................................... 23

Table 8 Fuchu Infrastructure Management Plan .................................................................. 30

Table 9 Difference in Annual Infrastructure Management Cost between Planned and As-is

(keeping current level) .................................................................................................... 31

Table 10 Comprehensive Outsourcing by Kiyosato-cho, Hokkaido .................................... 33

Table 11 Comprehensive Outsourcing by Ozora-cho, Hokkaido ........................................ 33

Table 12 Criteria for Selection of New Technologies .......................................................... 36

Table 13 New Technologies Used in Japan ......................................................................... 37

Table 14 Special Issues on Infrastructure Management in JSCE Magazine ........................ 61

Table 15 Major Defects of Bridges in OECD Countries ...................................................... 76

Table 16 Maintenance Costs in OECD Countries ................................................................ 77

Table 17 Recent Surface Transportation Assistance Act and Budget .................................. 80

Table 18 Chronological Table of the Adoption of PFI by the U.K. Government ................ 85

Table 19 Infrastructure Improvement Initiatives in the U.K. ............................................... 86

Table 20 Examples of Concession of Toll Roads by Type .................................................. 88

Table 21 Concession Period and Fee in the U.S.A and Europe ........................................... 89

Table 22 Time Introduced PBMC by State .......................................................................... 90

Table 23 Details of Comprehensive Road Management Project in the City of Portsmouth 92

Table 24 Details of Comprehensive Road Management Project in the City of Birmingham93

Table 25 Details of Hounslow Borough Comprehensive Road Maintenance Project ......... 94

Table 26 New Major Technologies Used in Europe ............................................................ 98

Table 27 Comparison of Infrastructure Management Initiatives in Japan, U.S.A. and U.K.103

Table 28 Classification of Japanese Technologies and Know-how that are More Easily

Applied than those of the U.S.A. and Europe .............................................................. 105

Table 29 Infrastructure Improvement Plan (2013 – 2020) ................................................. 108

Table 30 Roles of National Government Organizations .................................................... 110

Table 31 Institutional Status of the Target Organizations and Infrastructure Maintained . 111

Table 32 Trend of DPT’s Budget and its Budget for Maintenance .................................... 120

Table 33 Priority Issues in BMA’s Budget for the Year 2015 ........................................... 121

Table 34 BMA’s Budget of Recent Years (2012-2014) ..................................................... 122

Table 35 Budget Appropriation to Departments (2013-2014) ........................................... 122

Table 36 Breakdown of Budget for Repair and Maintenance ............................................ 122

Table 37 List of Road Categories ....................................................................................... 124

Table 38 Budget for Road Departments in MOT ............................................................... 125

Table 39 Regulation and Manuals for Roads and Bridges ................................................. 126

Table 40 DOH Road Length by Surface Type ................................................................... 127

Table 41 Section Length by Road Type ............................................................................. 127

Table 42 Breakdown of Maintenance Budget .................................................................... 129

Table 43 Code No. of the Maintenance Budget ........................................................ 130

Table 44 History of Road Surface Condition Survey ......................................................... 135

Table 45 Inspection Data of Overweight Trucks ............................................................... 135

Table 46 Result of Road Surface Condition Survey .......................................................... 138

Table 47 List of Expressways Managed by EXAT ............................................................ 155

Table 48 Main Information of Cable-Stayed Type Bridges in EXAT Expressways ......... 156

Table 49 Trends of Length of Expressway and Number of User Cars, 2008 to 2013 ....... 158

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

vii

Table 50 Trends of Income Statement Results, 2008 to 2013 ............................................ 158

Table 51 Trends of Balance Sheet, 2008 to 2013 ............................................................... 158

Table 52 Breakdown of Tangible Fixed Assets, as of the end of September 2013 ............ 159

Table 53 Major Financial Index ......................................................................................... 159

Table 54 Trend of Maintenance Costs ............................................................................... 159

Table 55 Forecast of Revenue and Expense ....................................................................... 160

Table 56 Role of Each Sub-Unit of Expressway Maintenance Division ........................... 160

Table 57 Bridge Inspection Sheet ...................................................................................... 174

Table 58 Trend of Length of Distribution Pipes ................................................................ 187

Table 59 List of Regions and Branch Offices .................................................................... 187

Table 60 MWA’s Statement of Income ............................................................................. 188

Table 61 Operating Costs for Maintenance ........................................................................ 188

Table 62 MWA’s Balance Sheet ........................................................................................ 189

Table 63 Physical Fixed Assets .......................................................................................... 190

Table 64 Major Financial Index ......................................................................................... 190

Table 65 Water Leakage Causes and Repair Works .......................................................... 192

Table 66 Number of Asbestos and PVC Pipe Water Leaks ............................................... 195

Table 67 Change in Pipeline Replacement Plan ................................................................ 195

Table 68 Number of Branches by Group ........................................................................... 198

Table 69 PWA’s Statement of Income ............................................................................... 199

Table 70 PWA’s Balance Sheet ......................................................................................... 200

Table 71 Physical Fixed Assets .......................................................................................... 200

Table 72 Major Financial Index ......................................................................................... 201

Table 73 PWA’s Business Strategy ................................................................................... 201

Table 74 SRT Trunk Lines and Length .............................................................................. 210

Table 75 SRT’s Statement of Income ................................................................................ 213

Table 76 Number of Derailment Accidents ....................................................................... 213

Table 77 Type of Railway Track ........................................................................................ 213

Table 78 Usage of Type of Sleeper .................................................................................... 214

Table 79 MRTA’s Statement of Income ............................................................................ 218

Table 80 Power Volume Supplied by EGAT by Buyer ..................................................... 222

Table 81 Length of Transmission Lines by Capacity ......................................................... 222

Table 82 EGAT Main Facilities and Capacity ................................................................... 223

Table 83 EGAT Consolidated Statement of Income .......................................................... 224

Table 84 EGAT Consolidated Balance Sheet .................................................................... 224

Table 85 Fixed Assets and Depreciation Period (as of 2013 December) ........................... 225

Table 86 Major Financial Index ......................................................................................... 225

Table 87 MEA Main Facilities and Capacity (2006) ......................................................... 227

Table 88 MEA Statement of Income .................................................................................. 229

Table 89 MEA Balance Sheet 2011-2012 .......................................................................... 229

Table 90 MEA Fixed Assets (As of 2012 December) ........................................................ 230

Table 91 Major Financial Index ......................................................................................... 230

Table 92 PEA’s Main Infrastructure Facilities ................................................................... 232

Table 93 PEA Statement of Income ................................................................................... 233

Table 94 Breakdown of Fixed Assets ................................................................................ 248

Table 95 Length of Pipes by Type and Material ................................................................ 249

Table 96 Length and NRW Ratio of Distribution Branch Pipe and Service Pipe .............. 250

Table 97 Characteristics and Usage in Scenario 2 by Pipe Type ....................................... 253

Table 98 Comparison of Benefit over LCC by Pipe Type (200mm) ................................. 254

Table 99 Comparison of Benefit over LCC by Pipe Type (400mm) ................................. 254

Table 100 Pipe Types and Replacement Plan by Scenario ................................................ 255

Table 101 Forecast of the Yearly Volume of Revenue Water ........................................... 256

Table 102 Legal Service Life and Number of Water Leaks by Pipe Type ........................ 257

Table 103 NRW Rate of Distribution Branch Pipe and Service Pipe in 2013 ................... 257

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

viii

Table 104 Change in NRW Rate by Pipe Type and by Age .............................................. 257

Table 105 Pipe Replacement Cost by Pipe Type and Pipe Size ......................................... 258

Table 106 New Pipe Installation Plan (PVC pipe) ............................................................. 258

Table 107 List of MWA’s Pumps ...................................................................................... 259

Table 108 Accumulated Operation and Maintenance Costs and NRW Rate ..................... 263

Table 109 Accumulated Operation and Maintenance Costs of Pumps and Cost Savings by

Scenario ........................................................................................................................ 266

Table 110 Cost Benefit Ratio and O &M Cost Ratio for Scenarios ................................... 267

Table 111 Length of Expressway by Organization in Charge of Maintenance .................. 269

Table 112 Data of Expressway ..................................................................................... 270

Table 113 Proposed Scenarios to be Compared ................................................................. 272

Table 114 Dimensions to be Used for Examination of Corrective Maintenance Scenarios273

Table 115 Description of Two Preventive Maintenance Scenarios ................................... 276

Table 116 Dimensions to be Used for Examination of Preventive Maintenance Scenarios276

Table 117 Result of Case Study ......................................................................................... 279

Table 118 Basic Policy of Examining Countermeasures ................................................... 282

Table 119 Conditions for Case Study ................................................................................ 283

Table 120 Result of Case Study ......................................................................................... 285

Table 121 Long Life Pavement Main Technologies .......................................................... 285

Table 122 The Number of Participants by Organization.................................................... 286

Table 123 The Number of Participants by Organization.................................................... 292

Table 124 Number of Responses to be Interesting by Topic ............................................. 294

Table 125 Key Messages Important for Infrastructure Management ................................. 295

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

ix

Abbreviations

AAR

Association of American Railroads

AASHTO

American Association of State Highway and Transportation Officials

ACI American Concrete Institute

ADB Asian Development Bank

AEC ASEAN Economic Community

AIT

Asian Institute of Technology

AM Asset Management

AMS Asset Management System

ANRE Agency of Natural Resources and Energy (Japan)

ASCE

American Society of Civil Engineers

BMA Bangkok Metropolitan Administration

BMMS Bridge Maintenance and Management System

BMS Bridge Management System

BMTA Bangkok Mass Transit Authority

BOB Bureau of the Budget

BOT

Build, Operate and Transfer

BSI British Standard Institution

CFRP Carbon Fiber Reinforced Plastics

CRD Central Road Database

DBFO Design, Build, Finance and Operate

DBO Design, Build and Operate

DEDE Department of Alternative Energy Development and Efficiency

DfT Department for Transport

DIS Draft International Standard

DMA District Management Area

DOE Department of Energy

DOH Department of Highways

DPT Department of Public Works and Town & Country Planning

DRR Department of Rural Roads

DSD Drainage and Sewage Department

EGAT Electricity Generating Authority of Thailand

EPA Environmental Protection Agency

ERC Energy Regulation Commission

ERO Electric Reliability Organization

EXAT Expressway Authority of Thailand

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

x

FERC Federal Energy Regulatory Commission

FHWA Federal Highway Administration

FPO Fiscal Policy Office

F/S Feasibility Study

GASB Governmental Accounting Standards Board

GIS Geographic Information System

HA Highways Agency

HDM Highway Design Manual

HERS-ST Highway Economic Requirements System-State Version

HPMS Highway Performance Monitoring System

IAM

Institute of Asset Management

ICE Institute of Civil Engineers

IPE Independent Power Plant

IRI International Roughness Index

ISO International Organization for Standardization

JICA Japan International Cooperation Agency

LCC Life Cycle Cost

MEA Metropolitan Electricity Authority

METI Ministry of Economy, Trade and Industry

MHLW Ministry of Health, Labour and Welfare (Japan)

MIC Ministry of Internal Affairs and Communications (Japan)

MLIT Ministry of Land, Infrastructure, Transport and Tourism (Japan)

MNRE

Ministry of Natural Resources and Environment

MOE Ministry of Energy

MOI Ministry of Interior

MOF Ministry of Finance

MOT

Ministry of Transport

MRTA Mass Rapid Transit Authority

MWA Metropolitan Waterworks Authority

NBI National Bridge Inventory

NBIS National Bridge Inspection Standards

NESDB National Economic and Social Development Board

NETIS New Technology Information System

NIP National Infrastructure Plan

ODA Official Development Assistance

Ofgem Office of Gas and Electricity Markets

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

xi

Ofwat Water Services Regulation Authority

OGC Office of Government Commerce

O&M Operation and Transfer

ORR Office of Rail Regulation

PBMC Performance-Based Maintenance Contracting

PC Pre-stressed Concrete

PDCA Plan Do Check Action

PDMO Public Debt Management Office

PEA Provincial Electricity Authority

PFI Private Finance Initiative

PMMS Pavement Maintenance and Management System

PMS Pavement Management System

PPP Public Private Partnership

PSO Public Service Obligation

PVC polyvinyl chloride

PWA Provincial Waterworks Authority

RMMS Routine Pavement Maintenance and Management System

SAP Session Announcement Protocol

SCADA Supervisory Control And Data Acquisition

SEPO State Enterprise Policy Office

SOE State Owned Enterprise

SRT State Railway of Thailand

TAM Transportation Asset Management Guide

TPMS Thailand Pavement Management System

VMS Variable Message Sign

WMA Wastewater Management Authority

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

1

1 Outline of the Survey

Background

1.1

In Japan, infrastructure facilities such as roads, bridges and water supply and sewerage systems

were constructed during the country’s rapid economic growth in the 1960’s. Service life of such

infrastructure facilities is on average several decades, and many facilities have and will have

aged by the 2010’s. Therefore, in Japan, infrastructure facility management to appropriately

maintain and repair facilities, extending their life periods while giving due consideration to

budgetary constraints, has recently been given deep and widespread attention.

In Thailand, the heavy construction period for infrastructure facilities for the purpose of

attracting foreign investment started in the 1980’s. Considering the fact that its history of

infrastructure development follows that of Japan by two decades, we can assume that aging of

infrastructure facilities will become serious concern in Thailand in a decade or two. Moreover,

Thailand is still promoting new infrastructure construction to keep up its economic competence

with the world, which means Thailand may need to take care of both aging infrastructure

facilities and new construction.

Given these circumstances, it is beneficial for Thailand to learn from the lessons that Japan

gained through its trial and error process and apply precautionary measures before their

infrastructure facilities age and cause serious problems, in order to keep their competent

position in the world. To this aim, Japan International Cooperation Agency (JICA) will conduct

this data collection survey study and examine the current situation of infrastructure facilities in

Thailand, their maintenance, and their management especially in light of the issues surrounding

aging infrastructure, in order to develop recommendations on necessary measures to be taken.

Definition of Infrastructure Management

1.2

In this study ‘Infrastructure Management’ is defined as methods and methodologies to

comprehensively plan, manage and operate civil infrastructure systems. Sometimes the term

‘asset management’ is used in similar situations. This term means economically and technically

rational maintenance plans for each facility and equipment and methodologies for their

implementation. Asset management for each facility is based on comprehensive infrastructure

management.

Objectives

1.3

JICA conducts this study with the following three objectives.

1) Introduce the idea of infrastructure facility management, which can extend life periods of

infrastructure facilities by managing their routine preventive care and maintenance.

2) Introduce Japanese technologies and skills for infrastructure facility management.

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

2

3) Examine possibility of Japan’s support using Official Development Assistance (ODA)

and/or application of technologies and expertise from Japanese companies.

Scope

1.4

1.4.1 Target Location

City of Bangkok and neighboring municipalities

1.4.2 Target Organizations

The following organizations will be contacted to obtain necessary information.

1) Office of Prime Minister /Bureau of the Budget

2) Ministry of Finance (Public Debt Management Office, State Enterprise Policy Office)

3) Office of Prime Minister /National Economic and Social Development Board (NESDB)

4) Ministry of Interior/ Department of Public Works and Town & Country Planning (DPT)

5) Bangkok Metropolitan Administration (BMA)

6) Metropolitan Waterworks Authority (MWA)

7) Provincial Waterworks Authority (PWA)

8) Wastewater Management Authority (WMA)

9) Ministry of Transport/ Department of Highways (DOH)

10) Ministry of Transport/ Department of Rural Roads (DRR)

11) Expressway Authority of Thailand (EXAT)

12) State Railway of Thailand (SRT)

13) Mass Rapid Transit Authority (MRTA)

14) Electricity Generating Authority of Thailand (EGAT)

15) Metropolitan Electricity Authority (MEA)

16) Provincial Electricity Authority (PEA)

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

3

1.4.3 Target Facilities

Various public structures can be considered as infrastructure facilities. The target facilities and

areas are selected based on information of the facilities that the target organizations are

responsible for.

Table 1 Target Areas and Facilities

Target areas Target facilities

Administrators

Ministries

Munici-

palities

Public

corporations

Roads

- Highways,

- National roads,

- Local roads

Pavements, bridges,

tunnels

MOI/DPT

MOT/DOH

MOT/DRR

BMA EXAT

Water supply Dams, purification

plants, pipelines,

pumping stations

MOI/DPT MWA, PWA

Sewerage Pipelines, sewerage

treatment plants,

pumping stations

MOI/DPT BMA WMA

Railways

- National railways

- Mass Rapid Transit

Bridges, viaducts,

stripline structures,

fixtures and fittings

SRT MRTA

Electricity Powerhouse,

Substation,

distribution line

MOI/DOE EGAT, MEA

PEA

MOI/DPT Ministry of Interior/ Department of Public Works and Town & Country Planning

MOT/DOH Ministry of Transport / Department of Highways

MOT/DRR Ministry of Transport / Department of Rural Roads

EGAT Electricity Generating Authority of Thailand

BMA Bangkok Metropolitan Administration

WMA Wastewater Management Authority

MWA Metropolitan Waterworks Authority

PWA Provincial Waterworks Authority

SRT State Railway of Thailand

MRTA Mass Rapid Transit Authority

MEA Metropolitan Electricity Authority

PEA Provincial Electricity Authority

EXAT Expressway Authority of Thailand

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

4

Implementation Structure

1.5

1.5.1 Study Schedule

1.5.2 Detailed Plan of Study

A. First Study in Japan

A.1 Formulation of the study plan

The Study Team studied all available information, i.e. materials collected by the Study Team

and any other projects. The Study Team will then summarize the basic policy, project

methods, operation itemization and content, and study schedule.

A.2 Collection of information on infrastructure management in Japan through

literature research

The Study Team collected the information on infrastructure management in Japan.

Table 2 Contents of the Initial Study

Items Contents

Information

sources in Japan

Sources of similar

information

in Thailan

d

a. Current situation

of aging

infrastructure

facilities

Current situation of

infrastructure facilities (past

record-keeping, maintenance

skills)

Segregation of duties between

national and local levels

Local

governments

NESDB, BMA

Legal systems

(Regulation on use of private

sector funds etc.)

Ordinance

governing

ministries

Bureau of the

Budget, SEPO

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

5

b

.

N

ational

governments’

approaches

National government

measures and policies

MIC NESDB

MLIT DPT

c. Municipalities’

Approaches

Measures and policies

Projects

Financial plans

Infrastructure

management plan

MWA, PWA, DOH,

DRR, EXAT, SRT,

MRTA, EGAT,

MEA, PEA, BMA

d. Private sector

technologies

and expertise

Products and technologies,

Performance

Overseas businesses Overseas

expansion plans

General

contractors,

Bridge makers,

Consultants etc.

Thai Obayashi,

Research institutions

MLIT Ministry of Land, Infrastructure, Transport, and Tourism

MIC Ministry of Internal Affairs and Communications

A.3 Comparison of infrastructure management approaches and assessment of

strengths of Japanese approaches

The Study Team then put all information collected together and compare situations and

various approaches, such as administrative structures, legal systems, policies, and private

sector’ technologies and expertise in each area between those applied in Japan and in other

developed countries, based on a similar literature research on non-Japanese examples as

described above.

B. First Study in Thailand (June 29 – August 9)

B.1 Explanation of contents of inception report

The Study Team explained the contents of the inception report, study plan, and summary of

findings from the literature research on various aspects related to infrastructure facility

management approaches in Japan and other developed counties.

B.2 Holding of workshop

A workshop was held with the purpose of disseminating and discussing project objectives and

methods for 59 participants from the Thai side (from NESDB, SEPO, BMA, MWA, PWA,

DOH, DRR, EXAT etc.). The Study Team will ask the participants for cooperation in

meeting with Study Team for interviews and providing necessary information and data for

assessment.

B.3 Interview of relevant organizations

In order to learn how each task in the PDCA cycle as shown in Table 3 is implemented in

Thailand, the Study Team visited each organization a few times.

Data Collection Survey on Infrastructure Management in Thailand JICA

Final Report KOKUSAI KOGYO CO., LTD.

6

Table 3 Queries based on PDCA to Administrative Organizations in Thailand

PDCA Data category Sample interview topics

PLAN

Laws, standards,

policies, and plans

Laws, standards, regulations, and rules

governing infrastructure management

Infrastructure management plans in existence,

including facility-specific plans

Infrastructure management policies, related

governmental policies and direction of change

(if any)

Overall management

structure

Whether responsibility is assigned to specific

agencies/organizations for each

infrastructure/facility/equipment

Budget management Maintenance budget categories

DO

Inspection system

Infrastructure/facility/equipment targeted by

inspection-based management – locations and

quantity

Current state of ageing of infrastructure

/facility/equipment, i.e. latest results from

inspections

Detailed inspection procedures and manuals