TOYOTA CAMRY 2015 - 17” ALLOY WHEEL

Preparation

Page 1 of 14 pages

DIO

Issue: A 2/12/14

Part Number: PT758-03140

Kit Contents

Item # Quantity Reqd. Description

1 4 per vehicle Al Wheel 17”x 7.0”x 40mm

Hardware Bag Contents

Item # Quantity Reqd. Description

1 1 per wheel Center Cap

PT385-33070-WC

2 0~5 per wheel

as needed

OE Flat-Seat Lug Nut

P/N 90084-94001

Additional Items Required For Installation

Item # Quantity Reqd. Description

1 1 per wheel Tire: P215/55R17 93V

Michelin Primacy MXV4

OR Bridgestone TURANZA

EL400-02 (Recommended)

2 As Required Balance Weights Lo-Profile

Stick-on Type

3M TN-2023 or equivalent.

3 0 - 4 as needed TPMS 20-degree angle

Single DIO P/N 42607-06020

4 1 OE 17” Tire Pressure Label

Conflicts

Recommended Tools

Personal & Vehicle

Protection

Notes

Safety Glasses

Seat Protection Blanket

Special Tools Notes

Tire Changing Machine Hunter TC3200,

or Corghi Artiglio Master 26

or equivalent.

Wheel Balancing Machine Hunter GSP9700,

or equivalent.

Centering Cone Hunter BACK-SIDE collet

192-52-2 or equiv.

Wing Nut Hunter 76-371-3 or equiv.

4.5 inch Cup w/ Sleeve Hunter 175-353-1 or equiv.

4.5 inch protector Sleeve Hunter 106-82-2 or equiv.

Foot Brake Application Tool Snap-on B240A Pedal Jack

or equivalent.

Toyota Diagnostic Tester

or Techstream Device

Software Version 13.2a or

newer required.

Installation Tools Notes

Lug Nut Wrench 21 mm wrench flat

Rubber Mallet

Torque Wrench 20-150 ft-lbf (27-204 N-m)

Torque Wrench 30-150 in-lbf (3.3-17 N-m)

Sockets 11mm and 21 mm

Deep Well, Thin Wall

4 inch extension (as needed) For TPMS torque wrench

Valve Stem Torque Tool Snap-On QDTPMS or equiv.

Nylon Panel Removal Tool e.g. Panel Pry Tool #1

Toyota SST # 00002-06001-01

Valve Stem Removal Tool Schraeder Valve Type

Wire Brush Hand held size

Clean Lint-free Cloth

Special Chemicals Notes

Tire Lube Myers or equivalent

Cleaner (for rework of stick

on weights if needed)

Locally approved cleaner

General Applicability

Applicable to 2015+ Toyota Camry.

Use with tire size P215/55R17 93V

Recommended Sequence of Application

Item # Accessory

1 17”Alloy Wheel & 17” OE Tire

2 Optional Wheel Locks, PN 00276-00900

Vehicle Service Parts (May be required for reassembly)

Item # Quantity Reqd. Description

1 0 – 4 as needed Valve Stem Grommet Fitting

Kit

P/N 04423-0E010

2 0 – 4 as needed TPMS 20 degree angle

Single P/N 42607-06020

Legend

STOP: Damage to the vehicle may occur. Do not proceed

until process has been complied with.

OPERATOR SAFETY: Use caution to avoid risk of injury.

CAUTION: A process that must be carefully observed in

order to reduce the risk of damage to the

accessory/vehicle and to ensure a quality installation.

TOOLS & EQUIPMENT: Used in Figures calls out the

specific tools and equipment recommended for this

process.

REVISION MARK: This mark highlights a change in

installation with respect to previous issue.

SAFETY TORQUE: This mark indicates that torque is

related to safety.

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 2 of 14 pages

DIO

Issue: A 2/12/14

Care must be taken when installing this accessory to ensure damage does not occur to the vehicle. The installation of this

accessory should follow approved guidelines to ensure a quality installation.

These guidelines can be found in the "Accessory Installation Practices" document.

This document covers such items as:-

Vehicle Protection (use of covers and blankets, cleaning chemicals, etc.).

Safety (eye protection, rechecking torque procedure, etc.).

Vehicle Disassembly/Reassembly (panel removal, part storage, etc.).

Electrical Component Disassembly/Reassembly (battery disconnection, connector removal, etc.).

Please see your local dealer for a copy of this document.

1. Prepare the Vehicle.

(a) Firmly apply the parking brake.

(b) Put automatic transmission in "P" (Fig. 1-1).

Put manual transmission in “R”.

(c) Add seat protection (blanket) and apply the

foot brake using a foot brake application tool

as needed (Fig. 1-2).

(d) Lift the vehicle.

(e) Remove the OE wheel and tire assembly from

the vehicle (Fig. 1-3). Wear safety glasses

while removing the wheels.

(f) If required, remove any corrosion on the

mounting surface of the vehicle with a wire

brush (Fig. 1-4). Wear safety glasses to

protect against any debris.

Fig. 1-2

Foot Brake

Application Tool

Fig. 1-1

Fi

g

. 1-4

Wire Brush

Fig. 1-3

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 3 of 14 pages

DIO

Issue: A 2/12/14

2. Remove Tire Pressure Monitor Valve

Sub-assembly.

NOTE: 20 degree Tire Pressure Sensors

MUST stay with the same vehicle!

40 degree sensors are NOT re-used on ANY

Accessory Alloy Wheels! (Fig. 2-1)

(a) Remove & retain the valve stem cores and

release the air from all four tires.

(b) Remove & retain the nuts and washers and let

the pressure sensors drop inside the tires.

(c) Carefully separate the upper tire bead from the

wheel rim (Fig. 2-2).

NOTE: Be careful not to damage the tire

pressure monitor due to interference between the

sensor and the tire bead.

(d) Remove the sensor from the tire and remove

the bead on the lower side as in the usual tire

removal operation.

(e) Dismount the OE tire from the OE wheel.

(f) Repeat for all four tires.

Fig. 2-1

Fig. 2-2

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 4 of 14 pages

DIO

Issue: A 2/12/14

3. Install the Tire Pressure Monitor Sensor

(TPMS) Sub-assembly into Accessory Wheels.

(a) If the previously removed sensor is a 20

degree sensor, proceed to step 3(c). If the

previously removed sensor is a 40 degree

sensor, you must install new 20 degree sensors

into accessory wheels. When installing new 20

degree sensors, you MUST record sensor ID

codes for all four wheels and register these

four new ID codes (Fig. 3-1) with the vehicle

ECU. Each sensor has a unique sensor ID

code. The sensor ID code is a 7 or 8-character

hexadecimal string comprised of numbers 0

through 9 and letters A through F. See Fig. 3-

1 for example code and location.

(b) IMPORTANT! Record all four new TPMS

ID codes onto a sheet of paper or in a shop

notebook. These MUST be programmed into

the vehicle ECU later in Step 10.

(c) Check that the wheel valve hole is clean and

free of sharp edges or burrs.

(d) Visually check that there is no deformation or

damage on the tire pressure monitor valve

sub-assembly. Check that the grommet,

washer and nut are all clean and in good

condition.

NOTE: Replace the grommet ONLY IF the

grommet is old or was damaged. A damaged

grommet is NOT reusable.

Fig. 3-1

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 5 of 14 pages

DIO

Issue: A 2/12/14

(e) Insert the tire pressure monitor valve sub-

assembly into the wheel valve hole from the

inside of the rim and bring the valve stem to

the outside (Fig. 3-2).

(f) Insert the tire pressure monitor valve sub-

assembly so that the sensor ID number and

text is visible (Fig. 3-1 & Fig. 3-2).

NOTE: Incorrect orientation of the pressure

monitor sub-assembly may cause damage and

prevent signal transmission during high-speed

driving.

(g) Install the washer on the outside of the wheel

and secure with the nut.

Torque the nut to 36 in-lbf (4.0 N-m)

4. Mount the Tires.

IMPORTANT: If the vehicle came with 17 inch

OE tires, reuse the OE 17 inch tires. In any case,

use four OE/new P215/55R17 93V tires.

(a) Use tire lube on the tire beads and bead

locations on wheel prior to mounting the tire.

(b) Position the wheel on the mounting machine

with the sensor at ~ 7 o'clock position (shaded

area in Fig. 4-1)

(1) The mount/dismount head is considered as

12 o'clock position.

(c) Mount the lower tire bead.

NOTE: If the sensor is positioned outside this

area, it generates interference with the tire bead,

possibly causing damage to the sensor.

(d) Reposition the wheel on the mounting

machine with the sensor at ~ 7 o'clock

position (shaded area in Fig. 4-1).

Nut

Rim

Tire

Tire Valve

Sensor

Grommet (Rubber)

Valve Cap

Washer (Metal)

Fig. 3-2

Rim

Rotating

Direction

Area for the

Sensor (60 deg)

12 o’clock Position

Mounting Machine

Head

Rim

Fig. 4-1

UPPER AND LOWER BEAD PLACEMENT

CLOCKWISE ROTATION

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 6 of 14 pages

DIO

Issue: A 2/12/14

(e) Mount the upper tire bead.

NOTE: If the Mounting Machine rotates in the

counterclockwise direction, refer to Fig. 4-2 for

sensor placement

.

NOTE: Make sure that the tire bead and tool do

not interfere with the main body of the sensor and

the bead does not clamp sensor.

(f) To seat the tire beads, inflate the tire beyond

35 PSI but not more the than the maximum

tire bead seat pressure indicated on the tire

sidewall. If it is not indicated, use 40 PSI as a

limit. If the tire bead is not seated when

pressure registers 40 PSI, deflate the tire and

re-inflate it to seat the beads.

(g) Install and torque the valve stem cores with

the valve stem torque tool.

(h) Regulate the tire pressure to:

FRONT: 35 PSI (240 kPa)

REAR: 35 PSI (240 kPa)

(i) Recheck the torque on the TPMS nuts and

install the valve stem caps.

5. Balance the Wheels.

NOTE: Application temperature for stick-on

type weight is above 50°F (10°C). Weights should

be no taller than 4 ~ 5 mm in height. It is good

practice to apply the stick-on type in sections

comprised of no more than 5 or 6 individual

weight segments.

(a) Remove the tire labels from tire tread.

UPPER AND LOWER BEAD PLACEMENT

Rim

Rotating

Direction

Rim

Mounting Machine

Head

12 o’clock Position

Area for the

Sensor (60 deg)

Fig. 4-2

COUNTER-CLOCKWISE ROTATION

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 7 of 14 pages

DIO

Issue: A 2/12/14

(b) Mount the wheel/tire assembly on the wheel

balance machine and balance in DYNAMIC

MODE. Enable the LOAD ROLLER, if

applicable, to ensure proper bead seating. Use

3M TN-2023 or equivalent lead-free stick-on

type weights (Figs. 5-1 & 5-2).

(c) Prior to mounting stick-on weight, use a 50-50

Simple Green & Water solution (or

equivalent locally approved cleaner), as

needed, to clean the weight mounting location

on wheel, then wipe down with a clean, dry,

lint-free cloth. Ensure that the location is

clean and dry. Apply stick-on type weights at

perimeter location identified by dynamic

balance machine, as shown. Use a rubber

mallet, if required, to achieve complete

adhesion of stick-on type weight(s).

NOTE: Maximum stick-on type weight is 100 g

(3.5 oz.) on the inner plane and 100 g (3.5 oz.) on

the outer plane. If weight required exceeds this,

place machine in STATIC mode and proceed. If

weight required still exceeds limit, rotate the tire

180 degrees relative to the wheel and repeat Step

5. If removal and replacement of stick-on type

weight is necessary, remove the weight using a

nylon removal tool. Clean the surface with a

clean cloth using locally approved cleaning

solution. Wipe the surface dry before re-applying

new weight(s). (DO NOT RE-USE STICK-ON

WEIGHTS.)

Fig.5-1

Use 3M TN-2023 Stick-On

Type Tape-Weight or

equivalent lo-profile weight.

Fig.5-2

Detail of Outboard Plane Stick-On Type Weight

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 8 of 14 pages

DIO

Issue: A 2/12/14

(d) Re-spin the wheel on the machine with the

LOAD ROLLER DISABLED (if applicable)

and note the indicated remaining unbalance.

The maximum permitted unbalance is 6 g

(0.21 oz.) at inner and 6 g (0.21 oz) at outer

location. If the indicated unbalance is not

within the permissible limit, add required

additional balance weights, within

specification, and re-spin the tire/wheel

assembly.

6. Record the Tire Identification Number (TIN).

(a) Record ALL four new 17” Tire Identification

Numbers (TINs) from the four new 17” tires

installed onto the vehicle. Record these TINs

with the Vehicle Identification Number (VIN).

The TIN for the tire is an 11 or 12 character

string located after the “DOT” symbol on the

sidewall of the tire.

(b) Provide the tire information to your tire

vendor as required by law. Skip this step if

the OE 17” tires will be reused.

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 9 of 14 pages

DIO

Issue: A 2/12/14

7. Install the Center Caps.

(a) Install the center caps into wheels as shown in

Fig. 7-1 & 7-2. Be sure to orient the

TOYOTA logo relative to the valve hole (6

O’clock) as shown.

8. Install the Vehicle Wheel / Tire.

(a) Install the wheel/tire assemblies onto the

vehicle. Hand start the lug nuts during

installation. Install one (optional) wheel lock

per wheel (excluding the spare) at the 12

O’clock, or top position, opposite the valve

stem (Fig. 8-1).

(b) Tighten the lug nuts in sequence 1 through 5

(Fig. 8-2). Ensure that the socket does not

scuff the wheel. Tighten to 103N-m (76 lbf-

ft) using a torque wrench.

Torque: 103 N-m (76 lbf-ft)

(c) Re-torque all of the lug nuts in same the 1-5

sequence (Fig. 8-2).

Torque: 103 N-m (76 lbf-ft)

CAUTION: DO NOT USE AN IMPACT

WRENCH TO INSTALL OR REMOVE

WHEEL LOCKS.

(d) Remove the vehicle from the lift.

Fig. 8-1

Wheel Lock a

t

To

p

Valve Stem at Botto

m

Fi

g

. 8-2

Fig. 7-1

Valve Stem at Bottom, or at 6 o’clock position.

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 10 of 14 pages

DIO

Issue: A 2/12/14

9. Tire Pressure Labels.

This wheel reuses the OE 17 inch tires, and

therefore no accessory labels are required. Ensure

that the vehicle has an OE 17 inch tire pressure

label located on the driver’s side door jamb.

10. TPMS Transmitter ID Registration.

Perform ONLY when replacing the sensors.

Skip to Step 12 if reusing the same 20 degree

sensors on same vehicle.

Skip to Step 11 if using a Techstream Device.

(a) Complete this section after all four wheels

have been installed.

(b) Connect the hand-held tester to DLC3 (Fig.

10-1).

(c) Turn the ignition switch to the ON position.

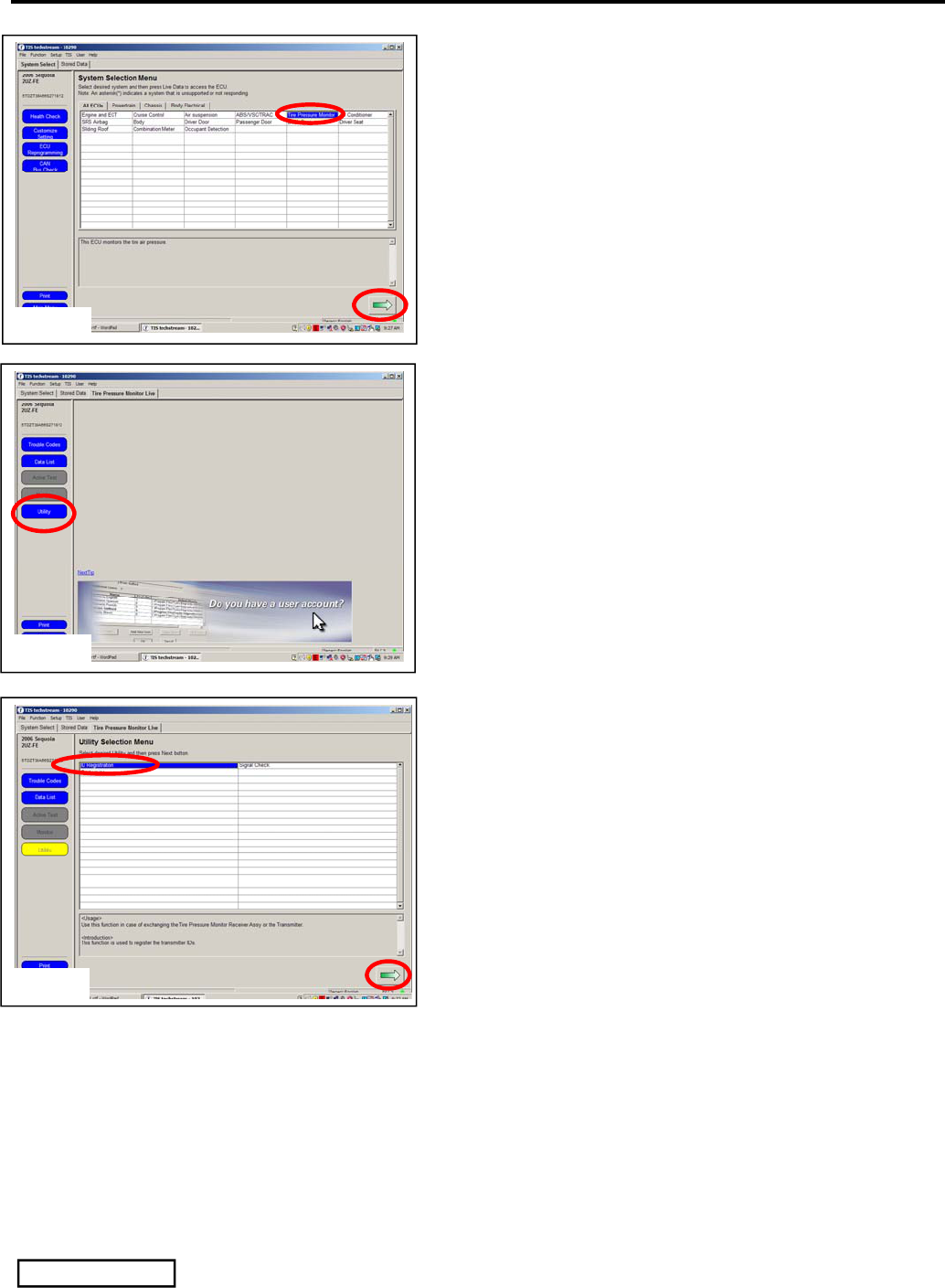

(d) Turn the Tester on and Select UTILITY -

REGIST TIRE following the hand-held tester

screen prompts (Fig. 10-2 & Fig. 10-3).

(e) Input the TPMS ID codes (ID1 to ID4) from

Step 3(b) using the hand-held tester to

transmit them to the tire pressure monitor

ECU.

NOTE: The spare tire does NOT have TPMS.

(f) Make sure that the ID transmission condition

“SUCCEEDED” is achieved.

(g) Confirm all the tire pressures are set to values

recommended on the tire pressure label for

this vehicle.

NOTE: If this process is not completed within 5

minutes, the transmitter will return to normal

operation mode and the process will need to be

started over at Step 10(d).

Fig. 10-1

Fig. 10-2

Fig. 10-3

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 11 of 14 pages

DIO

Issue: A 2/12/14

11. TPMS Transmitter ID Registration Using

Techstream.

(a) Connect the Techstream to DLC3, as in Fig.

10-1.

(b) Turn the ignition switch to the ON position

(do not start the vehicle) then turn the

Techstream ON.

(c) Start the Techstream application by clicking

on the shortcut located on the Desktop.

(d) Click “Connect to Vehicle” button (Fig. 11-

1).

(e) Confirm that the information displayed on the

Vehicle Connection Wizard is correct. If not,

make the appropriate selections from the Drop

Down Menus, then click “Next” (Fig. 11-2).

Fig. 11-2

Fig. 11-1

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 12 of 14 pages

DIO

Issue: A 2/12/14

(f) Select “Tire Pressure Monitor” then click

the green arrow located on the bottom right

(Fig. 11-3).

(g) Select “UTILITY” to begin input of new

TPMS ID codes (Fig. 11-4).

(h) Select “ID Registration” then click the green

arrow located at the bottom right corner (Fig.

11-5).

Fig. 11-4

Fig. 11-5

Fig. 11-3

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Procedure

Page 13 of 14 pages

DIO

Issue: A 2/12/14

(i) Select “Next” for Steps 1 through 3. Select

“Input” in Step 4 to begin TPMS ID

registration (Fig. 11-6).

(j) Input the TPMS ID code then click “OK”

Repeat the same procedure for all other TPMS

ID codes (Fig. 11-7).

NOTE: If this process is not completed

within 5 minutes, the transmitter will return to

normal operation mode and process will need

to be started over at Step 11 (g).

(k) After all TPMS ID numbers have been

registered, “ID Registration is complete” text

should be displayed. Click “Exit” to finish

the registration process (Fig. 11-8).

(l) Select “DATA LIST” to view and confirm the

TPMS ID numbers have been correctly

registered (Fig 11-9).

12. Breakdown of OE Tire & Wheel Assembly

(a) Sort product properly according to local

regulations.

Fig. 11-6

Fig. 11-7

Fig. 11-8

Fig. 11-9

TOYOTA Camry 2015 - 17” ALLOY WHEEL

Checklist - these points MUST be checked to ensure a quality install.

Check: Look For:

Page 14 of 14 pages

DIO

Issue: A 2/12/14

Inspect lug nuts.

Check lug nut torque.

TPMS sensor torque.

Correct Tire Pressure

Tire Identification Numbers

(Needed only if replacing the OE tires.)

Center Caps

Optional Wheel Locks

Verify five lug nuts are installed on each

wheel.

Verify the Torque is 76 ft-lbf (103 N-m).

TPMS nut must be torqued to 4.0 N-m (36

lbf-in).

Verify the tire pressure is set to the value

specified on the OE 17 inch Tire Pressure

Label.

Provide the tire information to your tire

vendor as required by law if OE tires are

replaced.

Verify center caps are securely in place on

all four wheels.

Verify the Wheel Lock Key Tool is in the

appropriate location in vehicle and the

respective paperwork is placed into vehicle

glove compartment.

Vehicle Appearance Check

After accessory installation and removal of

protective cover(s), perform a visual

inspection.

Ensure no damage (including scuffs and

scratches) was caused during the

installation process.

(For PPO installations, refer to TMS

Accessory Quality Shipping Standard.)