version 15.1

1

NASA Rally Sport General Regulations for Rallies

Copyright

2003 - 2020

All rights reserved. This book is an official

publication of

NASA Rally Sport.

The contents of this book are the sole property of NASA Rally Sport.

No portion of this book may be reproduced in any manner,

electronically transmitted, posted on the internet, recorded by any

means, or stored on any magnetic / electromagnetic storage system

s) without the express written consent from the management board of

NASA Rally Sport.

This document may be printed for personal use.

NASA Rally Sport East

PO Box 13756

Durham, NC 27709

Email [email protected]

Phone 919.697.5282

NASA Rally Sport West

25422 Trabuco Rd, Suite #105-276

Lake Forest, CA 92630

Email [email protected]

Phone 646.535.4240

National Auto Sport Association National Office

P.O. Box 21555

Richmond, CA 94820

Phone 510.232.NASA (6272)

NASARallySport.com

Some portions of this book were reprinted with permission from the

copyright owners, and NASA Rally Sport lays no claim to any

copyright to that material whatsoever. NASA Rally Sport would like to

thank the Canadian Association of RallySport and Motorsports New

Zealand for the use of their regulations as a source for this regulatory

document.

2

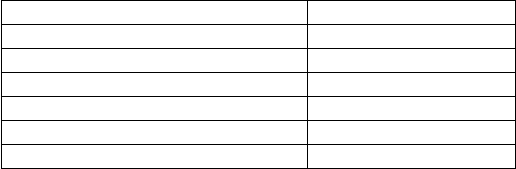

3 TECHNICAL REGULATIONS FOR CARS..............................6

3.1 Vehicle Class Rules Overview.................................................6

3.2 Vehicle Class - Open AWD Heavy and Light...........................7

3.2.1 Definition............................................................................7

3.2.2 Engine Displacement.........................................................7

3.2.3 Authorized Modifications....................................................7

3.2.4 Weight................................................................................8

3.2.5 Electronic Controls.............................................................8

3.2.6 Sequential Transmissions..................................................9

3.3 Vehicle Class - Open 2WD Heavy and Light...........................9

3.3.1 Definition............................................................................9

3.3.2 Engine Limitation................................................................9

3.3.3 Authorized Modifications..................................................10

3.4 Vehicle Class – Super Open / Exhibition...............................10

3.5 Vehicle Class – PRO.............................................................10

3.5.1 Definiton...........................................................................10

3.5.2 License.............................................................................11

3.6 Vehicle Class – ELE Electric..................................................11

3.6.1 Definition..........................................................................11

3.6.2 Battery Limitation.............................................................11

3.7 Vehicle Class - Stock Heavy, Medium, and Light..................11

3.7.1 Definition..........................................................................12

3.7.2 Engine Limitations............................................................12

3.7.3 Original equipment...........................................................12

3.7.4 Additional Specifications for Stock Heavy........................13

3.7.4.1 Wheels........................................................................13

3.7.4.2 Brakes........................................................................13

3.7.4.3 Minimum weight..........................................................13

3.7.5 Normal work and repair....................................................13

3.7.6 Authorized Modifications for Stock Classes.....................13

3.8 Vehicle Class - Group N........................................................19

3.8.1 Homologation...................................................................19

3.8.2 Safety Regulations for Homologated Group N4...............19

3.9 Roll Cage / Rollover Protection..............................................20

3.10 Seats....................................................................................20

3.11 Safety Harness....................................................................20

3.11.1 Condition........................................................................20

3.11.2 Placement......................................................................20

3.11.3 Safety Wiring..................................................................20

3.11.4 Hardware........................................................................21

3.11.5 Anchorage - Lap Belts....................................................21

3.11.6 Anchorage - Crotch Belt(s).............................................21

3.11.7 Anchorage - Shoulder Belts...........................................21

3.11.7.1 Shoulder Belts Reinforcement Bar............................21

3.11.7.2 Shoulder Belt Reinforcement Bar Attachment..........21

3.11.8 Shoulder Belt Placement................................................21

3

3.11.9 New Anchorage Reinforcement.....................................21

3.11.10 Principles of Mounting to the Chassis/Monocoque.......22

3.11.10.1 General Mounting System......................................22

3.11.10.2 Shoulder Strap Mounting........................................22

3.11.10.3 Crotch Strap Mounting............................................22

3.11.11 Manufacturer Instructions.............................................22

3.11.12 Vehicle Eligibility...........................................................22

3.11.12.1 Vehicle Registration................................................22

3.11.12.2 Street Legality.........................................................22

3.11.12.3 General Construction..............................................22

3.11.13 Vehicle Preparation Regulations..................................22

3.11.14 Vehicles Prepared to Technical Regulations of Other

Sanctioning Bodies......................................................................22

3.11.14.1 Documentation........................................................23

3.11.14.2 Rally America.........................................................23

3.11.14.3 Canadian Association of Rally Sport (CARS).........23

3.11.14.4 Federation Internationale de L’Automobile (FIA)....23

3.11.14.5 Federación de Automovilismo Deportivo (FAMD)...23

3.11.14.6 SCORE International..............................................23

3.12 Wheels.................................................................................23

3.13 Tires.....................................................................................24

3.13.1 Additional Tire Rules For Tarmac Events.......................24

3.13.2 Additional Tire Rules for Snow/Ice Events.....................24

3.14 Turbocharger/Supercharger Restrictors...............................24

3.14.1 Restrictor Sizes..............................................................24

3.14.2 Restrictor Specifications.................................................25

3.15 Fire Extinguishers................................................................26

3.15.1 Number..........................................................................26

3.15.2 Extinguishers..................................................................26

3.15.3 Maintenance...................................................................26

3.16 First Aid Kit..........................................................................26

3.17 Safety Triangles...................................................................26

3.18 Batteries...............................................................................27

3.18.1 Mounting........................................................................27

3.18.2 Housing..........................................................................27

3.18.3 Mounting within Passenger Compartment......................27

3.19 General Circuit Breaker.......................................................27

3.19.1 Recommended Use........................................................27

3.19.2 Location..........................................................................27

3.19.3 Labeling..........................................................................27

3.19.4 Road Worthiness Items..................................................27

3.20 Windows..............................................................................27

3.21 Window Winders..................................................................28

3.21.1 Use During Events.........................................................28

3.22 Window Nets........................................................................28

3.23 Window Films......................................................................28

4

3.24 Window Replacement..........................................................28

3.25 Lights...................................................................................28

3.26 Exhaust System...................................................................29

3.27 Fuel Tanks, Lines and Pumps.............................................29

3.27.1 Fuel Tank Bulkhead.......................................................29

3.27.2 Approved Fuel Cells.......................................................29

3.27.3 Supplemental Fuel Tanks...............................................30

3.27.4 Rerouting of Lines..........................................................30

3.27.5 Fuel Pump......................................................................30

3.27.6 Secondary Fuel Pumps..................................................30

3.27.7 Fuel Pump Bulkhead......................................................30

3.28 Towing Eyes........................................................................31

3.29 Loose Articles......................................................................31

3.30 Door Panels.........................................................................31

3.31 Tow Rope............................................................................31

3.32 Roofs...................................................................................31

3.33 Air Bags...............................................................................31

3.34 Mud Flaps............................................................................31

3.35 Power Door Locks...............................................................31

3.36 Steering Locking Device......................................................31

3.37 Camera and Camera Mounts...............................................31

3.38 Personal Safety Items for Occupants..................................31

3.38.1.1 Helmets....................................................................31

3.38.1.2 Suits..........................................................................32

3.38.1.3 Head and Neck Restraint Devices............................32

3.39 Definitions............................................................................32

5

3 TECHNICAL REGULATIONS FOR CARS

3.1 Vehicle Class Rules Overview

As an overview only, the following car classes are briefly described:

Open AWD Heavy - open class AWD turbo

Open AWD Light - open class AWD naturally aspirated

Open 2WD Heavy - open class 2WD turbo and large engine

Open 2WD Light - open class 2WD naturally aspirated

Super Open / Exhibition – any vehicles exceeding the specs

other available classes

Stock Heavy - large displacement turbo AWD stock cars

Stock Medium - powerful stock cars

Stock Light - less powerful stock cars

Group N - homologated FIA cars

PRO – Unlimited championship cars

ELE – Electric powered cars

6

3.2 Vehicle Class - Open AWD Heavy and Light

Philosophy: Open class vehicles allow any modification you can

dream up to the car, unless you are specifically told you can't do it by

a rule within Section 3.

Open AWD Class consists of modified four-wheel drive cars. The

class is split into two sub-classes:

1. Open AWD Heavy - four wheel drive with forced

induction engines

2. Open AWD Light - four wheel drive with naturally

aspirated engines

3.2.1 Definition

1. Any vehicle with a four-wheel drive driveline.

2. Vehicles which do not comply with Open AWD Heavy

Class but do comply with FIA regulations for Group A

rally cars (including World Rally Cars) are permitted to

compete in Open AWD Heavy class, but shall not be

eligible to score championship points.

3.2.2 Engine Displacement

Engine displacement after adjustment shall be no greater then 5100

cm

3

. Adjusted engine displacement is calculated by multiplying the

actual displacement by the multipliers listed below:

Open AWD

Heavy

Open AWD

Light

Rotary 1.8 1.8

Turbocharged 1.7 Disallowed

Four or more valves per cylinder 1.0 1.2

Three valves per cylinder 1.0 1.1

Two valves per cylinder 1.0 1.0

Pushrod 0.8 0.8

Diesel 0.8 0.8

3.2.3 Authorized Modifications

1. Except for restrictions listed within this class definition,

the modification, reinforcement, substitution, addition or

deletion of parts and components is permitted without

restriction, provided the vehicle complies with the safety

and general regulations.

2. Except for doors and roofs, bolt-on body pieces may be

constructed of an alternate material. The A and B pillars

must remain original. The original floor pan and firewall

7

must remain and may be modified only to the extent

necessary to accommodate allowed alternate

components. Roof mounted, commercially available

cooling vents are allowed.

3. Fenders modifications are allowed for the benefit of tire

clearance. The tires must be contained in the bodywork

when viewed above the car in a 90-degree perpendicular

angle to the ground.

3.2.4 Weight

1. The minimum weight limit of the car is determined by the

class and adjusted displacement.

Adjusted Displacement

in cubic centimeters

Weight Limit, in pounds

Open AWD

Heavy

Open AWD

Light

Up to 1000 2700 1585

over 1000 and up to 1150 2700 1735

over 1150 and up to 1400 2700 1850

over 1400 and up to 1600 2700 2025

over 1600 and up to 2000 2700 2200

over 2000 and up to 2500 2700 2375

over 2500 and up to 3000 2700 2530

over 3000 and up to 3500 2700 2700

over 3500 and up to 4000 2700 2885

over 4000 and up to 4500 2700 3080

over 4500 and up to 5000 2700 3300

over 4000 and up to 5500 2700 3500

over 5500 and up 2700 3700

2. This is the real weight of the car, without fuel, driver, co-

driver and their personal equipment.

3. If the weight is disputed during weighing then all the

driver and co-driver equipment, including helmets shall

be removed.

4. All transit headphones, tools, spare parts, tires and

wheels will remain in the car during weighing.

5. Securely fixed ballast may be used to realize the

absolute minimum real weight of the car.

3.2.5 Electronic Controls

Electronic control of the suspension, steering, braking, and

gear change/clutch, front and rear differentials are expressly

prohibited.

8

3.2.6 Sequential Transmissions

Sequential transmissions are prohibited with the exception of

automatic transmissions available as the vehicle is sold from

the dealer.

3.3 Vehicle Class - Open 2WD Heavy and Light

Philosophy: Open class vehicles allow any modification you can

dream up to the car, unless you are specifically told you can't do it by

a rule within Section 3.

Open 2WD Class consists of modified two wheel drive cars. The class

is split into two sub-classes:

1. Open 2WD Heavy: two wheel drive with adjusted

displacement over 2650 cm3

2. Open 2WD Light: two wheel drive with adjusted

displacement equal or less than 2650 cm3

3.3.1 Definition

1. Vehicles must be 2-wheel drive models sold globally in

minimum quantities of 1000.

2. Drive configuration must remain as originally

manufactured (e.g. front engine, front drive) with the

exception that a normally four wheel drive vehicle may

be reduced to either front or rear wheel drive as long

stock suspension pickup points are used and the floor

pan of the vehicle is not grossly modified for the

conversion.

3.3.2 Engine Limitation

Open 2WD

Heavy

Open 2WD

Light

Turbochargers Allowed Disallowed

NSU Wankel patents (Mazda rotary) Allowed Disallowed

Adjusted displacement less than 6000 cm3 2650 cm3

Adjusted displacement at least 2650 cm3 N/A

Adjusted engine displacement is calculated by multiplying the

absolute displacement by each of the relevant multipliers listed

below:

Open 2WD

Heavy

Open 2WD

Light

Rotary 1.8 Disallowed

Turbocharged/Supercharged 1.7 Disallowed

Four or more valves per cylinder 1.2 1.2

Three valves per cylinder 1.1 1.1

Two valves per cylinder 1.0 1.0

Pushrod 0.8 0.8

9

Diesel 0.8 0.8

3.3.3 Authorized Modifications

1. Except for restrictions listed within this class definition, the

modification, reinforcement, substitution, addition or deletion

of parts and components is permitted without restriction,

provided the vehicle complies with the safety and general

regulations.

2. Except for doors and roofs, bolt-on body pieces may be

constructed of an alternate material. A and B pillars must

remain original. The original floor pan and firewall must

remain and may be modified only to the extent necessary to

accommodate allowed alternate components. Roof mounted,

commercially available cooling vents are allowed.

3. Fenders modifications are allowed for the benefit of tire

clearance. The tires must be contained in the bodywork when

viewed above the car in a 90-degree perpendicular angle to

the ground.

4. Sequential transmissions are allowed.

3.4 Vehicle Class – Super Open / Exhibition

This class may be referred to by either the term “Super Open” or

“Exhibition”. Any vehicles not meeting the specifications or philosophy

for other open or stock classes can be placed into the Super Open /

Exhibition class. Examples of this would be some cars with sequential

transmissions, Group B cars, or WRC cars. Unless explicitly

discussed in championship regulations, Super Open / Exhibition cars

are not eligible to be considered for championships points.

3.5 Vehicle Class – PRO

Philosophy: more and more R5 and similar vehicles are competing

and these would normally run in Exhibition class. With the

proliferation of these cars and to provide these rocket ships a

meaningful battle against each other, PRO class was invented to

provide that arena, while simultaneously preserving fair and

affordable competition in other classes.

3.5.1 Definition

The vehicle must meet safety standards (cage, seats, belts,

construction, safety philosophy, etcetera) but is otherwise

unrestricted in performance aspects.

For additional clarity on PRO class:

• Sequential gearboxes are allowed

• Engine displacement is unlimited

• Turbo restrictors are not required

• Aerodynamic aids are allowed

10

3.5.2 License

The driver of a PRO class vehicle must have a PRO license. This

navigator is not required to have a PRO license.

3.5.3 Trophies

PRO class is designated as a championship-level class similar to

2WD or AWD.

3.6 Vehicle Class – ELE Electric

Philosophy: Vehicles that came from the manufacturer as all electric

vehicles, or vehicles converted to all electric operation. Hybrids are

not eligible for this class.

3.6.1 Definition

1. Vehicles may be 2 wheel drive or 4 wheel drive models sold

globally in minimum quantities of 1000, or initially based on

such a vehicle.

2. Drive wheels must remain as originally manufactured (front

wheel drive or rear wheel drive) with the exception that a

normally four wheel drive vehicle may be reduced to either

front or rear wheel drive as long stock suspension pickup

points are used and the floor pan of the vehicle is not grossly

modified for the conversion

3.6.2 Battery Limitation

The battery packs are unlimited. Non-stock installations must be

approved by NASA Rally Sport prior to acceptance of entry.

3.7 Vehicle Class - Stock Heavy, Medium, and Light

Philosophy: Stock class vehicles allow no modifications at all to the

car unless that particular modification is called out in the rules below.

If what you want to do is not listed below, it is not legal for stock class.

Stock Class consists of essentially showroom stock cars. The class is

split into three sub-classes:

1. Stock Heavy: specific turbocharged AWD cars with

superior performance to the typical showroom ready

vehicle. The following vehicles are specifically placed in

Stock Heavy unless prepared for another class.

a. 2004-present US Subaru STi

b. 2006 US Subaru WRX

c. 2004-2005 Mitsubishi Evo VIII

d. 2006-present Mitsubishi Evo IX

e. 2009-present Mitsubishi Evo X

f. 2004-2006 Volvo S40 T5 AWD

11

g. 2006-present Mazda Speed 6

2. Stock Medium: adjusted displacement over 2650 cm3

3. Stock Light: non-turbocharged, with adjusted

displacement equal or less than 2650 cm3

3.7.1 Definition

1. Sedans, station wagons, sports cars and light trucks,

available from manufactures listed in National Dealers

Association “Car Guide”, with limited modifications in

order to make them more suitable for competition with

respect to safety and reliability only.

2. There must have been a minimum of 1000 units of the

specific make and model and of a specific model year

commercially available in the United States.

3.7.2 Engine Limitations

Stock Heavy Stock Medium Stock Light

Turbochargers Allowed Allowed Disallowed

Rotary Does not apply Allowed Allowed

Adjusted displacement

less than

Unlimited Unlimited 2650 cm3

Adjusted displacement

at least

2650 cm3 2650 cm3 0 cm3

Adjusted engine displacement is calculated by multiplying the

absolute displacement by each of the relevant multipliers listed

below:

Stock Heavy / Medium Stock Light

Rotary 1.8 1.8

Turbocharged 1.7 Disallowed

Four wheel drive 1.3 1.3

Four or more valves per cylinder 1.2 1.2

Three valves per cylinder 1.1 1.1

Two valves per cylinder 1.0 1.0

Pushrod 0.8 0.8

Diesel 0.8 0.8

3.7.3 Original equipment

1. Original equipment is as defined in Article 3.39.

2. No updating or backdating of cars, models and/or

components is permitted.

3. Except where the removal, replacement or modification

is authorized under these regulations, all original

components and equipment installed by the vehicle's

12

manufacturer shall be present and functioning as

specified for the particular bodywork variant.

4. If an optional mechanical component is fitted to a vehicle

and that component is only offered by the manufacturer

in conjunction with other components, then all such

components must be fitted, except where deletion of any

of the components is authorized under these regulations.

5. It is the entrant's responsibility to provide manufacturer's

documentation such as sales brochures, workshop

manuals, service bulletins, etc., where necessary to

substantiate the eligibility of the vehicle and its

components.

3.7.4 Additional Specifications for Stock Heavy

3.7.4.1 Wheels

1. Gravel: Maximum permitted wheel is 15” x 7”

2. Tarmac: Maximum permitted wheel is 17” x 8”

3.7.4.2 Brakes

Brakes may be replaced with smaller diameter rotors and

smaller calipers to facilitate using 15” wheels on gravel events.

Homologated brake systems for the specific car are allowed.

The number pistons per caliper may not exceed the greatest

number standard on any of the listed cars.

3.7.4.3 Minimum weight

Vehicle Weight in pounds

2004-present US Subaru STi 3298

2006 US Subaru WRX 3192

2004-2005 Mitsubishi Evo VIII 3197

2006-present Mitsubishi Evo IX 3219

2004-2006 Volvo S40 T5 AWD 3230

2006-present Mazda Speed 6 3589

3.7.5 Normal work and repair

Except where authorized in these Regulations, the only work

permitted is the normal maintenance or replacement of parts

damaged through accident or wear. Except where specifically

authorized, all parts must be identical to the original part and

repairs must be according to the manufacturer's accepted

service instructions.

3.7.6 Authorized Modifications for Stock Classes

All items, which are not specifically allowed or referred to as

“free” below, must be of original manufacturer's specification.

Minor changes (such as a hole in the fire wall, etc) resulting from

authorized modifications are permissible

13

It is the entrant's responsibility to provide specification

documents, where necessary, to substantiate the eligibility of all

components, which are added under the following, authorized

modifications and might have an influence on performance. The

specification documents must demonstrate both function and

capability of the component.

1. Lighting Devices - Additional lighting is permitted, but

must conform to Article 3.25.

2. Cooling System - If, for the same vehicle model,

radiators of different capacities are normally offered,

they may be used. The addition of a radiator screen is

authorized. The make and type of thermostat are free. A

single oil cooler and necessary fittings may be added.

3. Induction - All Engines - The elements that control the

quantity of fuel fed into the engine may be modified, but

not those which control the volume of air. The original air

filter (OEM specification) and air filter housing may not

be modified, however the components upstream of the

housing may be moved, modified or removed. All air

entering the engine must pass through the air filter.

4. Induction - Carbureted engines - The carburetor(s)

normally mounted on the recognized model may not be

changed or removed.

5. Induction - Fuel Injected Engines - The Fuel injection

normally mounted on the recognized model may not be

changed or removed. Boost on turbocharged or

turbocharged vehicles is unrestricted and a manual

boost control and associated hardware is authorized.

The electronic control unit and the ignition components

in the electronic control unit are free; nevertheless the

system must be entirely interchangeable with the original

unit. The original wiring loom must be kept and cannot

be modified. Sensors and actuators on the input side

must be standard, as must their function. No sensor may

be added, even for the purpose of data recording. It is

prohibited to add a switch in the original wiring loom

between the electronic control unit and a sensor and/or

actuator.

6. Induction - Turbocharging/ Supercharging Systems -

Turbocharger and supercharger units must remain as

supplied by the vehicle manufacturer on that model.

Intercoolers may in no way be modified, moved or

added.

7. Exhaust -The exhaust system is free, except that the

stock exhaust manifold(s) must be retained. The pipe(s)

must exit behind the driver and external to the body. A

14

functioning catalytic converter must be present in the

exhaust system.

8. Electrical Equipment -The original equipment alternator

and the battery may be replaced, provided the location

remains unchanged, and provided they are commercially

available units of equal or larger electrical capacity. The

manufacture of the battery and alternator are

unrestricted.

9. Transmissions - Any transmission and transmission

controls normally installed by the manufacturer in the

same model may be used.

10. Differentials - If for the same model different final drive

ratios are normally offered and installed by the

manufacturer, they may be used. If the original vehicle is

fitted with a differential controlled by an electronic

system, the electronic control unit is free, but must be

entirely interchangeable with the original unit (i.e. the

differential must work when the unit is replaced with the

OEM unit). Sensors and actuators on the input side must

be standard, as must their function. No sensor may be

added, even for the purpose of data recording. The use

of "locked" and “limited slip “differential units are

allowed.

11. Shock Absorbers - Shock absorbers are free, provided

that their number, their type (telescopic, arm, etc.), their

working principle (hydraulic, friction, mixed, etc.), and

their attachment location remain unchanged. Shock

absorbers attachment points may be reinforced. The

damper tanks may be attached onto the unmodified shell

of the cars. If the shock absorbers have separate fluid

reserves located in the cockpit, or in the truck if this is

not separated from the cockpit, these must be strongly

fixed and must have a protection. A silent block may be

replaced by a "Uniball" joint, but only on condition that

the shock absorber has no guiding function. Gas filled

dampers, regarding their working principle, will be

considered as hydraulic dampers. If, in order to change

the damping element of a McPherson suspension, or a

suspension operating in an identical manner, it is

necessary to replace the entire McPherson strut, the

replacement parts must be mechanically equivalent to

the original ones and have the same mounting points.

For McPherson suspensions, the shape of the spring

seats is free. The material of the spring seats is free.

12. Suspension - The reinforcing of the structural parts of

the suspension (with the exception of anti-roll bars) and

15

its anchorage points by the addition of material is

allowed. Braces of the strut towers are allowed provided

no alterations are made to the induction system or air

filtration system. The suspension reinforcements must

not create hollow sections and must not allow two

separate parts to be joined together to form one. The

spring seats may be adjustable if the adjustable

structural part is a part of the spring seat and is

separated from the original suspension parts/bodywork

(it may be removed). The freedoms in spring length do

not authorize a reduction in the ride height below the

limit in the official factory shop manual. The length of the

coil springs is free, as is the number of coils, the wire

diameter, the type of spring (progressive or not), the

external diameter and the form of the spring seats. The

length, width, thickness and vertical curvature of the leaf

springs are free. The diameter of the torsion bars is free.

Stock anti-roll bars may be removed or replaced. The

reinforcing of the structural parts of the suspension (with

the exception of anti-roll bars) and its anchorage points

by additional material is allowed. The roll cage may be

used to brace the vehicle’s suspension.

13. Brakes - Brake linings are free, as well as their

mountings (riveted, bonded, etc.) provided that the

contact surface of the brakes is not increased. Protection

plates may be removed or bent. In the case of a car

fitted with servo-assisted brakes, this device may be

disconnected and removed. The anti-lock braking

system (ABS) may be disabled and or removed. If the

anti-lock braking system (ABS) is disconnected, the use

of a mechanical rear-braking distributor (e.g. pressure

limiting valve) is authorized. Brake lines may be changed

for aviation type lines and rerouted. A device for

scraping away the mud, which collects on the brake,

discs or the wheels, may be added.

14. Clutch and Pressure Plate with Flywheel - The disc is

free, including the weight, with the exception of the

number. The diameter of the clutch disc may be

increased. The flywheel must be made of the same

material as offered from the vehicle manufacturer and

must meet the manufactures minimum specifications for

weight.

15. Fuel Cells and Fuel Lines - It is permitted to replace

the original fuel tank with an approved fuel cell.

16. Motor Mounts - Free provided the stock location is

maintained for the mounting for the engine and

16

transmission. The location of the engine and

transmission may not be affected.

17. Engine - Over boring for the use of oversize pistons is

prohibited.

18. Additional accessories - All accessories, which have

no influence on the car's behavior, for example

equipment that improves the aesthetics or comfort of the

car interior (lighting, heating, radio, etc.), are allowed

without restriction. In no case may these accessories

increase the engine power or influence the steering,

transmission, brakes, or road holding, even in an indirect

fashion. All controls must retain the role laid down for

them by the manufacturer. They may be adapted to

facilitate their use and accessibility, for example a longer

handbrake lever, an additional flange on the brake

pedal, etc. The following are allowed:

a. Fasteners and their locking mechanism are free.

b. Measuring instruments such as speedometers

etc. may be installed or replaced, and possibly

could have different functions. Such installations

must not involve any risk. However, the

speedometer may not be removed.

c. The horn button may be changed and/or an

additional one added, within reach of the

passenger. The horn is not compulsory on closed

venue events.

d. Additional electrical relays, switches, wiring,

fuses and circuit breakers may be installed.

e. Engine throttle cables may be replaced. The

manufacture is free. If the series vehicle is fitted

with a motorized throttle valve, a throttle kit with a

mechanical linkage may be used.

f. The steering wheel is free. The locking system of

the anti-theft steering lock may be rendered

inoperative. Quick release mechanism are

allowed.

g. Additional compartments may be added to the

glove compartment.

h. Additional pockets in the doors provided that they

use the original panels.

i. The luggage compartment may be modified to

allow the safe installation of equipment, toolbox,

and additional spare wheels.

j. Cruise Control systems may be rendered

inoperative.

17

k. Anti-theft systems may be rendered inoperative.

l. Insulating material may be added to the existing

bulkheads to protect the passengers from fire.

m. Removal of standard radio/stereo systems is

permitted

n. Exterior Bodywork

• Roof mounted cooling vents are allowed.

• Hubcaps must be removed.

• Protective headlight covers may be fitted

provided that their only function is to cover the

glass and they have no influence on the car's

aerodynamics.

• The fitting of underbody protections is

authorized provided that these really are

protections which respect the ground

clearance, which are removable and which are

designed exclusively and specifically in order

to protect the following parts: engine, radiator,

suspension, gearbox, tank, transmission,

steering, exhaust, extinguisher bottles.

• Any locking system may be used for the cap of

the petrol tank.

• The changing of the front and rear windscreen

wiper blades is authorized.

• In case of damage, all transparent parts must

be replaced by identical original equipment

parts

o. Interior Bodywork

The front seats may be moved backwards but

not beyond the vertical plane defined by the

front edge of the original rear seat.

The rear seat may be removed.

The dashboard and the central console must

remain original except where required for fitting

the roll cage.

Side, roof, pillar, door and rear moldings may

be removed or modified. Interior lighting may

be removed or modified

It is permitted to replace electric window

winders with manual ones.

Floor Carpets are free and may thus be

removed.

The original heating equipment must be

retained. The air conditioning system may be

removed provided if certain elements are

18

common with the heating system they must be

retained. The air conditioning compressor may

be removed provided that the only further

necessary modification is either removing a

drive belt, using a shorter drive belt, or adding

a free-spinning idler pulley in place of the

compressor.

19. Chassis - Seam welding the bodywork is permitted.

20. Non-durable parts - All normally non-durable parts (oil

filters, air filters, spark plugs, fan belts, etc.) must be

replaced with others of equivalent OEM specifications.

The heat range of spark plugs is free.

21. Manufacturer’s Specifications - Any machining for

adjustment must meet the manufacturer's specification

including those for tolerances.

3.8 Vehicle Class - Group N

These Group N regulations include vehicles in the FIA Group N4,

2 liter 4WD turbocharged, and FIA Super 2000 classes.

3.8.1 Homologation

1. Series production touring cars which comply with the FIA

regulations for Group N, and comply with Appendix J,

Article 251, 252, 253 and 254, 254A, 255 of the FIA

technical regulations and the FIA homologation paper(s)

specified on the entry form for that particular vehicle.

Compliance with homologation papers shall be

determined based on interpretations of those papers in

accordance with the FIA standards and regulations.

2. Expiration of FIA Homologation will be extended by four

years. Vehicles whose extended homologation deadline

has passed will compete in the Stock Heavy class.

3. Homologation Papers: Entrants are required to present

originals of correct vehicle homologation papers bearing

an original ink stamp of the issuing FIA/ASN at

scrutineering to substantiate the eligibility of the vehicle

and its components.

3.8.2 Safety Regulations for Homologated Group N4

Safety regulations are as per FIA regulations.

19

Following are the vehicle rules that are not

related to classing. The vehicle rules from this

point onward apply to all vehicles.

3.9 Roll Cage / Rollover Protection

See the Roll Cage Appendix.

3.10 Seats

Seats shall be of one-piece construction, and shall be firmly mounted

to the floor of the vehicle in such a manner as to prevent the

movement of the seat in case of an accident. Aluminum seats (e.g.

Butler Built, Kirkey) are banned as of 3/1/05. Use of FIA

certified/homologated seats is required.

3.11 Safety Harness

Five, six or seven-point safety harness are required for both members

of the crew. It is not permitted to mix parts of seat belts. All harnesses

shall be of current FIA or SFI specification.

All SFI certified restraints must be maintained, inspected, and

replaced or rewebbed every two years. The two-year period runs from

the date of manufacture contained on the label attached to the

restraints. Example: SFI belts punched with 05/2011 expired 00:00:01

on 6/01/2013 (one second after midnight, early morning of the first of

June).

All FIA certified restraints may be used through December 31 of the

year of expiration contained on the label attached to the restraints.

FIA certified restraints contain the expiration date on the label

attached to the restraints, and not the date of manufacture.

3.11.1 Condition

The material of all straps, buckles, and hardware, shall be in new or

perfect condition and the system must function perfectly. The belts

must be replaced after every severe collision, and whenever the

webbing is cut, frayed or weakened due to the actions of chemicals

or sunlight.

3.11.2 Placement

The lap belt and crotch straps should not pass over the sides of the

seat but through the seat's provided holes.

3.11.3 Safety Wiring

If the manufacturer provides for safety wiring the locking bale or

clasp to prevent accidental unfastening of the belts from their

20

anchorage points, then it shall be necessary for the all such

components to be safety wired.

3.11.4 Hardware

All mounting hardware should be SAE grade 5 or better or metric

grade 8.8 or better.

3.11.5 Anchorage - Lap Belts

It is preferable that safety harnesses be installed on the OEM

anchorage points of the vehicle. The recommended locations of the

anchorage points are shown in drawing 253-42. If necessary a New

Anchorage Point meeting 3.8.10 may be constructed.

3.11.6 Anchorage - Crotch Belt(s)

The crotch belt(s) may attach either to the OEM anchorage points

for the OEM lap belts or to a New Anchorage Point meeting 3.8.10

installed below the seat.

3.11.7 Anchorage - Shoulder Belts

The preferred mounting of shoulder straps is to the safety roll cage

or to a reinforcement bar by means of a loop. New anchorage points

may be installed on the shell or the chassis.

3.11.7.1 Shoulder Belts Reinforcement Bar

The transversal reinforcement shall be a tube measuring at least

1.5 inch x .120 inch or 1.6 inch x .095 inch, made from cold drawn

seamless carbon steel. It is recommended that the bar be as close

as possible to the seats.

3.11.7.2 Shoulder Belt Reinforcement Bar Attachment

The straps may be attached by looping or by bolts. If bolts are

used an insert must be welded for each mounting point (see

drawings 253-17C and 253-53 for the dimensions). These inserts

will be positioned in the reinforcement tube and the straps will be

attached to them using bolts.

3.11.8 Shoulder Belt Placement

The shoulder belt anchorage must be such that the shoulder straps,

towards the rear, are directed downwards with an angle of between

10 degrees and 45 degrees to the horizontal from the rim of the

backrest, an angle of 10 degrees being recommended. The

maximum angles in relation to the centerline of the seat are 20

degrees divergent or convergent. (See diagram 253-42)

3.11.9 New Anchorage Reinforcement

For each new anchorage point created, a steel reinforcement plate

with a surface area of at least 16 square inches and a thickness of

at least 1/8th inch must be used.

21

3.11.10 Principles of Mounting to the Chassis/Monocoque

3.11.10.1 General Mounting System

See drawing 253-43.

3.11.10.2 Shoulder Strap Mounting

See drawing 253-44.

3.11.10.3 Crotch Strap Mounting

See drawing 253-45.

3.11.11 Manufacturer Instructions

A safety harness must be used in conformity with the

manufacturer’s instructions.

3.11.12 Vehicle Eligibility

3.11.12.1 Vehicle Registration

Each vehicle entered in a NASA Rally Sport event must have a

current and valid vehicle registration. This requirement may be

waived for closed venue events.

3.11.12.2 Street Legality

A valid state-issued registration will be accepted as evidence that

the vehicle meets appropriate regulations to operate on a public

road. Required equipment should remain in good operation

throughout the running of the event. Should the competing vehicle

be detained or removed from operation during an event by a law

enforcement officer, the competitor may not seek remedy or relief

under these Regulations. This requirement may be waived for

closed venue events.

3.11.12.3 General Construction

Vehicles eligible for events must be production based four wheeled

passenger vehicles generally available for purchase by the general

public. To this end, the frame, floor pan, basic body shell, and

firewall must remain original but may be modified for strength or to

accommodate legal components. Exterior bodywork and pieces

must be present and visually similar to the original components.

Otherwise non-eligible vehicles may compete at the discretion of

NASA Rally Sport. "One-off" vehicles specially built from the ground

up for competition use is prohibited.

3.11.13 Vehicle Preparation Regulations

All vehicles not otherwise excepted must at a minimum meet NASA

Rally Sport Technical Regulations.

3.11.14 Vehicles Prepared to Technical Regulations of Other

Sanctioning Bodies

Any allowances made herein apply only to vehicle passing technical

inspection. All rules regarding vehicle registration and insurance still

22

apply. Vehicle classing will be done according to the rules the event

is using.

3.11.14.1 Documentation

Vehicles competing under alternate technical regulations must bring

printed copies of those regulations, in their entirety, to the vehicle’s

technical inspection.

3.11.14.2 Rally America

Any vehicle with a Rally America log book that is currently legal to

run under Rally America rules may request to be inspected

according to that rule set. If passed, it is legal to compete at a NASA

Rally Sport event. NRS rules apply for all safety gear worn by the

racer.

3.11.14.3 Canadian Association of Rally Sport (CARS)

Any vehicle with a CARS log book that is currently legal to run under

CARS rules may request to be inspected according to that rule set.

If passed, it is legal to compete at a NASA Rally Sport event. NRS

rules apply for all safety gear worn by the racer.

3.11.14.4 Federation Internationale de L’Automobile (FIA)

Any FIA legal vehicle with homologation papers that is currently

legal to run under FIA rules may request to be inspected according

to that rule set. If passed, it is legal to compete at a NASA Rally

Sport event. NRS rules apply for all safety gear worn by the racer.

3.11.14.5 Federación de Automovilismo Deportivo (FAMD)

Any vehicle with a FMAD log book that is currently legal to run

under FAMD rules may request to be inspected according to that

rule set. If passed, it is legal to compete at a NASA Rally Sport

event. NRS rules apply for all safety gear worn by the racer.

3.11.14.6 SCORE International

Any vehicle with a SCORE cage tag that is currently legal to run

under SCORE rules, including having a current SCORE annual

inspection, may request to be inspected according to that rule set. If

passed, it is legal to compete at a NASA Rally Sport event. NRS

rules apply for all safety gear worn by the racer.

3.12 Wheels

1. The wheels are free, regarding the maximum diameter

and maximum width unless amended in specific class

regulations.

2. The use of wheels with lesser dimensions is permitted.

3. Wheels made from forged magnesium are forbidden

(including standard wheels).

23

4. Wheels attached via bolts may be changed to studs and

nuts provided that the number of attachment points and

the diameter of the threaded parts remain the same.

5. Air extractors added on the wheels are forbidden.

3.13 Tires

1. Tires are free.

2. The use of any device for maintaining the performance

of the tire with an internal pressure equal to or less than

the atmospheric pressure is forbidden. The interior of the

tire (space between the rim and internal part of the tire)

must be filled only with air or nitrogen.

3. The spare wheel may be brought inside the driving

compartment, on condition that it is firmly secured there

and the wheel is not installed in the space reserved for

the occupants.

3.13.1 Additional Tire Rules For Tarmac Events

1. A tread pattern depth of 5.5mm (6/32”) must be molded

into the tire and at all times during the event, the tread

depth of the tires must be not less than 1.6 mm (2/32”)

over at least three quarters of the tread pattern.

2. The method of measuring the tread depth shall be

averaging two measurements, both taken in the center

of the width of the tire, with the measuring points being

at the 10 o’clock and 2 o’clock positions.

3. Shaving of tires is permitted. Siping/grooving of tires is

permitted. Tires do not need to be homologated.

4. Full racing slick and some “DOT” R-spec road race tires

(some examples are Hoosier R3S04, A3S04 & A3S05;

Avon Tech R; Kumho ECSTAV710; Hankook Ventus

Z214, Goodyear GS-CS Eagle) are disallowed.

3.13.2 Additional Tire Rules for Snow/Ice Events

1. The use of tires with metal or plastic studs is allowed

only at designated snow/ice events.

2. The maximum stud length is 5 mm measured from

surface of the rubber of the tire.

3. Studs must be installed from the outside of the tire.

Studs made of screws or bolts which start inside the tire

and protrude through the tire carcass are prohibited.

3.14 Turbocharger/Supercharger Restrictors

3.14.1 Restrictor Sizes

Car Class Maximum Internal Restrictor Size

Open AWD Heavy 34 mm

24

Stock Heavy 34 mm

Stock Medium 32 mm

Stock Light 32 mm

Group N 33 mm

All other classes not required

3.14.2 Restrictor Specifications

1. All turbocharged cars listed as requiring restrictors must

be fitted with a restrictor fixed to the compressor housing

unless the compressor air inlet internal diameter is equal

to or smaller then the required restrictor internal

diameter.

2. All air used for feeding the engine must pass through

this restrictor.

3. The restrictor must be maintained for a minimum

distance of 3 mm measured downstream of a plane

perpendicular to the rotational axis situated at a

maximum of 50 mm upstream of a plane passing

through the most upstream extremities of the wheel

blades (see Appendix B drawing 254-4).

4. The required diameter must be complied with regardless

of the temperature conditions.

5. For the installation of the restrictor it is permitted to

remove material from the compressor housing and to

add material for the sole purpose of attaching the

restrictor onto the compressor housing.

6. The restrictor must be made from a single material.

7. The restrictor may be pierced solely for the purpose of

mounting and sealing, which if done must be carried out

between the mounting screws, between the restrictor (or

the restrictor/compressor housing attachment), the

compressor housing (or the housing/flange attachment)

and the turbine housing (or the housing/flange

attachment) (see Appendix B drawing 254-4).

8. In case of an engine with two parallel compressors, each

compressor must be limited to a maximum intake

diameter of 22.6 mm.

9. Diesel engine: For vehicles with diesel engines, the

restrictor must have a maximum internal diameter of 35

mm and an external diameter of 41 mm.

10. Championship Options - A championship may elect to

require tighter scruitneering control of the restrictors. If

so stated in the championship regulations, the following

25

rules also apply: The external diameter of the restrictor

at its narrowest point must be less than 38 mm, and

must be maintained over a distance of 5 mm to each

side.The mounting of the restrictor onto the turbocharger

must be carried out in such a way that two screws have

to be entirely removed from the body of the compressor,

or from the restrictor, in order to detach the restrictor

from the compressor. Attachment by means of a needle

screw is not authorized. The heads of the screws must

be pierced so that they can be sealed.

11. Restrictors in Group N cars must meet all Group N

regulations.

3.15 Fire Extinguishers

3.15.1 Number

One fire extinguisher with a minimum UL rating of 10 BC or two

each with a minimum rating of 5 BC must be installed inside the

passenger compartment. During installation, consideration must be

given to quick release and security of attachment. One fire

extinguisher must be located within easy reach of the Driver or Co-

Driver when seated.

3.15.2 Extinguishers

It is recommended that Halon or a similar gas be used. If a dry

powder unit is used, the unit should be shaken or rapped sharply at

frequent intervals to reduce the chance of the powder compacting.

3.15.3 Maintenance

Evidence must be produced that the fire extinguisher has been

purchased or recharged within the preceding two years.

3.16 First Aid Kit

A comprehensive first aid kit shall be carried in the passenger

compartment. The first aid kit must include:

1. Antiseptic (ointment or liquid)

2. Gauze pads or rolls

3. Adhesive tape

4. Arm sling

5. Safety pins

6. Scissors

7. 2 “space” blankets

8. First aid manual.

3.17 Safety Triangles

A minimum of three self-supporting, light-reflecting, daylight-visible

triangular warning devices shall be carried in the vehicle. One of

which must be located within easy reach of the Driver or Co-Driver

when seated. The minimum size of the triangle is 14 inches from tip of

the triangle to opposing side of the triangle.

26

3.18 Batteries

3.18.1 Mounting

Batteries must be securely mounted with metal-to-metal mounts.

3.18.2 Housing

If removed from the original location, all batteries shall be mounted

inside covered, non-conductive boxes.

3.18.3 Mounting within Passenger Compartment

If mounted inside the passenger compartment, batteries shall be

those that are completely sealed or so designed or modified to

prevent acid spillage.

3.19 General Circuit Breaker

3.19.1 Recommended Use

It is strongly recommended that a spark-proof general circuit

breaker with the capability of disconnecting all electrical circuits

shall be mounted in the passenger compartment. (Supplementary

wiring may protect the integrity of a computer.)

3.19.2 Location

If a circuit breaker is used, the location of the circuit breaker shall be

that which makes it easily operable by either member of the crew or

by persons outside the vehicle through either front door.

3.19.3 Labeling

If a circuit breaker is used, the location of the circuit breaker shall be

marked with a label showing a red spark in a white-edged blue

triangle.

3.19.4 Road Worthiness Items

Each vehicle must be road worthy and have the following equipment

in full functional condition:

1. Horn, windshield wipers, windshield washer

2. Inside rearview mirror and side mirror(s)

3. Foot brake and parking brake

3.20 Windows

The front windshield shall be laminated safety glass

All windows and windshields should be presented to scrutineering

free from structural damage minus small cracks and chips.

The front windshield must be replaced if it is structurally damaged

during the event. Failure to replace broken and or damage windows

shall be deemed a safety hazard and shall cause competitor to be

declared DNF.

27

3.21 Window Winders

It is encouraged to replace electric winders with manual ones. In all

cases, the competitor must be able to describe to the satisfaction of

the event Scrutineer the ability to escape from the car with the doors

closed.

3.21.1 Use During Events

Windows in the driver and co-driver doors must be rolled-up during

special stages.

3.22 Window Nets

Window safety nets are highly recommended.

All SFI certified window nets must be replaced every two years. The

two-year period runs from the date of manufacture contained on the

label attached to the window nets.

3.23 Window Films

The use of translucent and colorless anti-shatter films on glass side

windows is highly recommended. The use of silvered or tinted films is

also authorized provided that the openings in these films allow a

person outside the car to see the driver.

3.24 Window Replacement

In classes where it is permissible to replace glass side and rear

windows with Lexan, it should 1/8” or greater. However, competitors

must be able to display to the satisfaction of the event Scrutineer that

the mounting of the substitute windows will allow both emergency

escape from inside the car and access by rescue from the outside of

the car.

3.25 Lights

1. Headlights may be changed only if they retain the

original mounting points and the replacement units are

similar in outward shape to the original design.

2. A headlight shall be considered as any lighting device

throwing a beam toward the front of the vehicle (dipped-

beam, long range lamp, anti-fog lamp).

3. Auxiliary headlights may be fitted, provided the number

installed is even or, if odd, that the lights are

symmetrically mounted with one light in the center.

4. It must be possible to turn off all high-beam headlights

and auxiliary lights with a single switch, which must

leave the low-beam headlights functioning.

5. It must not be possible to operate any fog lights fitted

without the front marker lights and taillights operating.

6. Auxiliary reversing lights may be fitted. All reversing

lights may only switch on by engaging reverse gear.

28

7. It is not permitted to fit any device that can alter the

normal functioning of the brake lights.

8. The mounting of maneuverable searchlight(s) is

prohibited.

9. Headlights with high and low beams must be present

and functional.

10. Parking lights, taillights, brake lights, front and rear turn

signals must be present and functional

3.26 Exhaust System

The maximum permitted noise level from the exhaust system shall be

105 db (A scale) with the engine idling at 2500 RPM, measured from

a distance of 18 inches in an area 45 degrees either side from the

centerline of the exhaust outlet. The test shall be on level ground and

be free from any obstructions.

3.27 Fuel Tanks, Lines and Pumps

3.27.1 Fuel Tank Bulkhead

A fuel-resistant and fire-retardant plate or shield is required between

the passenger compartment and the compartment or area in which

the fuel tank is located.

For two-volume cars only, this structural partition may be made of

transparent, nonflammable plastic. As of January 1, 2007 two-

volume cars must be have a liquid proof container surrounding the

fuel cell and its filler holes. Such a container is recommended for

three-volume cars.

3.27.2 Approved Fuel Cells

The original fuel tank may be replaced or supplemented by a fuel

cell meeting either SFI 28.3 or FIA FT3 1999, FIA FT3.5, or FIA FT

5 specifications. The fuel cell(s) must be installed in a metal

container(s).

The manufacturer, the model, the exact specifications according to

which this tank has been manufactured, the homologation number,

the date of end of validity, and the series number, must be printed

on the fuel cell.

The fuel cell must be properly vented to the outside of the vehicle

from the compartment in which it is located.

All fuel cells may only be placed either in the original location of the

tank or in the luggage compartment.

All cars fitted with a fuel cell with filler neck passing through the

cockpit must be equipped with a non-return valve homologated by

the FIA. This valve, of the type ″with one or two flaps″, must be

29

installed in the filler neck on the tank side." The filler neck is defined

as being the means used to connect the fuel filler hole of the vehicle

to the fuel cell itself.

Should the fuel cell and its filler be located in the luggage

compartment, an outlet must be provided for fuel spilled in the

compartment.

Where fuel cells are installed in the passenger compartment of

vehicles such as “hatchback” variants, Article 3.27.1 above applies if

the fuel cell filler is located in the passenger compartment.

The aging of safety tanks entails a considerable reduction in the

strength characteristics after approximately five years. No bladder

shall be used more than five years after the date of manufacture,

unless inspected and recertified by the manufacturer for a period of

up to another two years.

3.27.3 Supplemental Fuel Tanks

Supplemental fuel tanks are permitted.

3.27.4 Rerouting of Lines

If fuel lines are re-routed through the passenger compartment, they

shall be in compliance with the following: (a) shall incorporate a

metallic casing. (If the metallic casing is not exterior to the line, a

verifiable sample must be presented at scrutineering.) And (b) shall

have a minimum of 200 psi rating and (c) no connectors may be

inside the passenger compartment except on the front and rear

bulkheads according to drawings 253-1 and 253-2.

If the manufacturer routs fuel lines through the passenger

compartment, it is recommended that they be in compliance with

this section.

3.27.5 Fuel Pump

When using a fuel cell it is permissable to relocate or replace a fuel

pump. All the fuel pumps must only operate when the engine is

running, except during the starting process.

3.27.6 Secondary Fuel Pumps

The fitting of a second fuel pump is authorized, but this must be only

a spare fuel pump, i.e. it cannot operate in addition to the authorized

pump. It must be connectable by means of a purely mechanical

device situated beside the pumps.

3.27.7 Fuel Pump Bulkhead

Fuel pumps and filters shall be isolated from the driver/co-driver by

a fireproof metal bulkhead.

30

3.28 Towing Eyes

Towing eyes shall be attached to the front and rear of the vehicle and

painted in yellow, red or orange.

3.29 Loose Articles

All articles which could be dangerous if left loose must be securely

restrained.

3.30 Door Panels

Inside door panels are required to provide protection from metal

edges.

3.31 Tow Rope

All vehicles must carry a tow rope.

3.32 Roofs

Movable metal sunroofs and/or roof panels must be fixed in the

closed position. Sunroofs and/or roof panels of any other material

must be replaced with metal and must be fixed in the closed position.

The finished work must be of equal or greater strength than the

permanent roof.

3.33 Air Bags

Airbags and their associated equipment must be disabled or removed

during competition.

3.34 Mud Flaps

Mud flaps are required on all rear wheels and driven wheels.

3.35 Power Door Locks

It is recommended that power door locks be rendered inoperative and

replaced with manually operated mechanisms.

3.36 Steering Locking Device

It is recommended that any steering locking device be rendered

inoperative.

3.37 Camera and Camera Mounts

Camera mounts and their attachment to the vehicle shall be of a safe

and secure design which would prevent either driver from being able

to strike any part of the mount. The camera shall be secured at a

minimum of two different points and neither attachment may be

elastic or plastic. Cameras small enough to be classified “bullet”

cameras or “lipstick” cameras are only required to have one

attachment point.

3.38 Personal Safety Items for Occupants

3.38.1.1 Helmets

All members of the crews competing in events pursuant to these

rules must wear helmets with one of the following ratings:

1.Snell Foundation SA2010, SAH2010 or newer. SA2010

helmets will expire December 31 2021.

31

2.British Standard 6658-85 Type A/FR, including all

amendments will be valid for 10 years from the date of

manufacture. If no manufacturing date sticker exists,

the helmet will be considered expired.

3.SFI Spec 31.1/2005 or newer

4.FIA Certification of 8860-2010 or newer

5.FIA Certification of 8859-2015 or newer

3.38.1.2 Suits

All members of the crews competing in stage rally and rally sprint

events must wear suits with one of the following ratings:

1. FIA Standard 8856-2000

2. FIA NORME 1986/1986

3. SFI 3-2A/5

4. SFI 3-2A/1 with fire resistant underwear

3.38.1.3 Head and Neck Restraint Devices

Use of a head and neck restraint system or device is mandatory

for all car drivers and car navigators. Acceptable certifications are:

SFI 38.1

FIA 8858-2002

FIA 8858-2010

An FIA sticker supercedes a SFI sticker.

Any system used must be installed, used, and maintained

according to the manufacturers directions. The driver is ultimately

responsible for the proper installation and use of these devices.

3.39 Definitions

These definitions apply to all of Section 3.

1. Model - All vehicles belonging to a production series,

distinguishable by a specific conception and general

exterior lines of the bodywork and by the identical

method of transmitting the engine power to the drive

wheels. Supercharged/turbocharged vehicles will be

considered as different models than normally aspirated

versions of the same car. The terms turbocharged and

turbocharged will be used interchangeably within this

document.

2. Model variant - A model may exist in several variants as

to bodywork (i.e.: 2 door sedan, 4 door sedan, coupe,

station wagon etc.) or with regard to mechanical

components.

3. Interior bodywork - cockpit and trunk

4. Exterior bodywork - All the entirely suspended parts of

the car licked by the air stream.

32

5. Chassis - The overall structure of the car around which

are assembled the mechanical components and the

bodywork including any structural part of the said

structure.

6. Original equipment - All items of standard or optional

equipment that could have been ordered with the

particular bodywork variant of the car, installed on the

factory production line, and delivered through a dealer in

the United States or, for group N, as provided for in the

homologation papers for the vehicle. Dealer installed

options, except as required by the manufacture directive

(no matter how common), are not included in this

definition.

7. Automatic Transmission - This is made up of a

hydrodynamic torque converter, a box with epicyclical

gears equipped with clutches and multi-disc brakes and

having a fixed number of reduction gears, and a gear

change control. The gear change can be achieved

automatically without disconnecting the engine and

gearbox, and thus without interrupting the engine torque

transmission. Gearboxes with continually variable

transmission are considered as automatic gearboxes.

8. Commercially Available - This shall be interpreted as

meaning that the general public is able to obtain a price

and reasonable delivery date for the specific make and

model.

33