COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 1 REV 7-2022

MODELS LMO-E-P, LMO-E-S, LMO-G-P & LMO-G-S

MINI ROTATING RACK OVEN

INSTALLATION, OPERATION & MAINTENANCE MANUAL

GAS OVENS: POST IN A PROMINENT LOCATION, THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE

LOCAL GAS SUPPLIER

RETAIN THIS MANUAL FOR FUTURE REFERENCE

LBC BAKERY EQUIPMENT, INC.

6026 31

ST

Ave NE

Tulalip, WA 98271, USA

Toll Free: 888-722-5686

Email: sales@lbcbakery.com

Website: www.lbcbakery.com

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 2 REV 7-2022

READ FIRST T

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND AND FOLLOW THE

INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL.

W A R N I N G

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS

AND LI

QUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE.

D A N G E R

W A R N I N G

IMPROPER INSTALLATION,

ADJUSTMENT, SERVICE OR

MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR

DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

C A U T I O N

ALWAYS KEEP THE AREA NEAR

THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

This LBC Rotisserie was manufactured to rigid standards. The appliance has been tested and is

listed by Intertek Testing Services (ETL Semko) and meets applicable safety and sanitation

standards.

A) The responsibility of the manufacturer is to supply suitable, comprehensive instructions and

recommendations for proper operation and maintenance.

B) All operations, maintenance and repair of this or any LBC Bakery Equipment appliance must be

performed by properly trained and qualified personnel, and all such operations, maintenance

and repair must be performed in a diligent manner. It is the responsibility of the

owner/operator to ensure proper training and diligence of any person coming into contact with

either the subject units or the output (product, fumes or otherwise) of the subject units. It is the

responsibility of the owner/operator to ensure that the subject units are installed and operated

in accordance with OSHA Standard 1910.263.

C) A regular periodic program of cleaning, inspection and maintenance must be established, and

comprehensive maintenance records maintained. It is the sole responsibility of the

owner/operator to establish, schedule and enforce the frequency and scope of these programs

in keeping with recommended practice and with due consideration given to actual operating

conditions.

D) The appliance must be operated within limits which will not exceed its working limits. It is the

responsibility of the user to operate this appliance in accordance with the rules and limits

described in this manual and the published product specification sheet, and in accordance with

the directions and instructions of the owner/operator of the appliance or employer, and in

accordance with applicable federal, state and local laws and ordinances.

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 3 REV 7-2022

TABLE of CONTENTS .

Read First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Lighting and Shutdown – Gas Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Conditions of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensions and Utility Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Startup Procedure and Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using the Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Illustrated Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 4 REV 7-2022

LIGHTING and SHUTDOWN – GAS OVENS .

Lighting Instructions

Daily use

1. Press the “Power” button to turn the oven on. Close the oven door.

2. Set the oven temperature to the desired operating temperature by pressing the up or down

arrow buttons next to the “Set Temperature” display.

After Long-term shut-down

1. Turn on the gas supply to the oven.

2. Lift the gas valve access door located below the control panel. Switch the gas valve “ON.”

Shut-Down Instructions

Daily Use

1. Press the “Power” button to turn the oven off.

Long-term shut-down

1. Lift the gas valve access door located below the control panel and switch the gas valve to

“OFF” position.

2. Turn off the gas supply to the oven.

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 5 REV 7-2022

CONDITIONS of INSTALLATION (Part 1 of 2))

.

LBC Bakery Equipment shall, for a fee contingent on site location and provided the conditions of

installation are met, provide a factory-authorized service agency to install the LBC Rotisserie. The job

site must be ready for the installation before LBC Bakery Equipment or its authorized agent arrives. If

the installation site is not properly prepared or if there are construction delays, the customer shall be

responsible for all expenses incurred during this delay. All expenses resulting from job delay or

extension, for reasons beyond the control of LBC Bakery Equipment, shall be the responsibility of the

customer. Installation shall be conducted during normal business hours. This installation is for a single

trip. Start-up and training are not included.

IN ALL CASES, THE ELECTRICAL, WATER AND DRAIN CONNECTIONS AND VENTILATION MUST MEET

ALL FEDERAL, STATE AND LOCAL CODES OR ORDINANCES.

It is the responsibility of the owner/operator to do the following:

A. Secure all required permits and meet all local code requirements.

B. Ensure the installation site is cleared and ready for installation before the authorized installer arrives

on site. The site shall be smooth and level.

C. Provide electrical utilities within five (5) feet of the installation location per the specifications

provided by LBC Bakery Equipment

D. Provide licensed trades person to make the final electrical and water connections.

E. Provide adequate ventilation, including vented hoods and associated roof penetrations.

F. Remove all packing materials, crates, etc. resulting from the installation.

G. Provide any sheet metal work required by local codes or otherwise to bridge gaps between

appliance and adjacent walls or other building structures.

Inspection and Uncrating

Upon receipt of shipments, all packages should be inspected, and all visible or concealed damages noted

and signed for on the bill of lading. Any other damages should be reported to the carrier within 10 days.

Freight damages are the responsibility of the consignee.

All orders for replacement products resulting in freight damages will be processed under LBC’s standard

terms. Any reimbursement or credit is the responsibility of the freight carrier.

Carefully unpack the oven and place it in a work area as near to the final installation position as possible.

Installation of this equipment must be performed by an authorized service

representative. Prior to installation verify that all electrical and gas supplies

coincide with the manufacturers data label located on the right side below the

service panel.

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 6 REV 7-2022

CONDITIONS of INSTALLATION (Part 2 of 2) )

The LMO oven ships with the following items please inspect your shipment to ensure that these

items were included.

• LMO Oven Rack

• Decorative hood front, sides and back pieces

If moving the oven through a 36” door opening it will be necessary to remove the oven door, door

latch, door hinges decorative valance and the rear panel.

Location

This appliance is not intended for outdoor use. This appliance is not intended for residential use.

This appliance is intended for commercial use in locations suitable for use as listed in this manual.

Clearances to combustible and non-combustible construction: 0” from back, sides and top.

This appliance is suitable for installation on combustible floors.

Installation Codes

For US Installation: The LMO oven must be installed in accordance with all State and local codes as

well as the National Electrical Code, ANSI/NFPA-70 (latest edition). Gas ovens must be installed in

accordance with the National Fuel Gas Code, ANSI-Z223-1/NFPA 54 (latest edition).

For Canadian installation: The LMO oven must be installed in accordance with all local codes. Gas

ovens must be installed in accordance with the CAN/CGA-B149.1 National Gas Installation Code

Gas Ovens: The appliance and its individual shutoff valve must be disconnected form the gas supply

piping system during any pressure testing of that system at pressures in excess of ½ psi.

Gas Ovens: The appliance must be isolated from gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test pressures

equal to or less than ½ psi.

Model Number Coding

Electric Oven Number Format: LMO-EX-Y-Z, where X = rack size (use 6 for 6-pan rack, 8 for 8-pan

rack), Y = voltage (use -208 for 208V, -240 for 240V and -480 for 480V) and Z = base (use -S for stand,

-P for proofer base). Example: LMO-E8-480-P is a 480V electric oven with an 8-pan rack and proofer

base.

Gas Oven Number Format: LMO-GX-Y-Z, where X = rack size (use 6 for 6-pan rack, 8 for 8-pan rack),

Y = gas type (use -N for natural gas, -LP for propane gas) and Z denotes the base (use -S for stand, -

P for proofer base). Example: LMO-G6-N-S is a natural gas oven with a 6-pan rack and stand.

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 7 REV 7-2022

DIMENSIONS and UTILITY CONNECTIONS .

-

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 8 REV 7-2022

INSTALLATION (Part 1 of 6) .

Installing Casters

If your LMO oven is mounted on a stand, install casters using the supplied fasteners. With the oven still

on the shipping pallet, slide forward and install the two front locking casters. Move the oven with stand

forward again onto a pallet truck. Lift the oven with stand from the pallet and install the two rear casters.

Lift the oven only at the lift points shown in illustration.

Oven Location

See the Dimensions and Utility Connections section of this manual for oven dimensions. Select a location

with a smooth level surface and with adequate room to operate the appliance. If the oven mounting

surface is not level, loosen the caster bolts and shim with washers above the caster plates until the oven

is level. Re-tighten the caster bolts.

Gas Ovens: Gas Supply Connections

Verify that the gas type supplied to the oven matches the gas type listed on the oven’s data label. The

gas supply line must be at least the equivalent of 3/4” iron pipe. Ensure the pipes are free and clear of

any dirt or obstruction. Corrugated lines must not be used.

Codes require installation of a gas shutoff valve in the gas line ahead of the oven.

WARNING:

All gas ovens must be mounted on a stand or proofer base.

DO NOT mount directly to a solid surface as the combustion

air intake is from the bottom side of the oven.

Lifting Points. Use adequate

material handling equipment to lift

the oven into place. NOTE: Oven

weight is 1100 lbs.

WARNING:

Install oven on a surface adequate to support the

weight of the appliance.

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 9 REV 7-2022

INSTALLATION (Part 2 of 6) .

See the Dimensions and Utility Connections section of this manual for gas connect point location.

Connect the gas supply line to the 3/4” NPT gas connection located at the rear of the oven. If the oven

is supplied with a flexible gas line, secure it to the oven and wall per the manufacturer’s specifications.

Use only connectors that comply with the Standard for Connectors for Movable Gas Appliances, ANZI

Z21.69 or Connectors for Movable Gas Appliances, CAN/CGA-6.16 with quick-disconnect devices that

comply with the Standard for Quick-Disconnect Devices for Use with Gas Fuel, ANZI Z21.41 or Quick

Disconnect Devices for Use with Gas Fuel, CAN 1-6.9.

Check the incoming gas pressure before the gas valve. Pressure must remain between 5 to 14 inch W.C.

for natural gas and 11 to 14 inch W.C. for propane gas - both with and without the burner firing.

Gas Ovens: Gas Type Conversion

1. Shut off the gas supply to the oven. Remove the bottom burner cover and the side access cover.

2. Disconnect the gas line at the top of the gas valve. Remove the four extended nuts at the bottom of

the burner assembly. Lower the burner out of the oven.

3. Remove the 15 orifice marked “65”. Use gas-approved Teflon tape to seal the orifices.

4. Replace the burner. Reconnect the gas line and replace the covers.

5. Check for leaks.

6. Operate the burner. Adjust the gas manifold pressure to 5” W.C. Supply pressure must remain

between 11 to 14 inch W.C. for propane gas - both with and without the burner firing.

7. Apply proper labeling to indicate (a) the correct gas type and (b) the pressure requirements on the

data plate and at the gas connection point.

Electrical Connections

WARNING:

Gas supply connections and any pipe joint compound must

be resistant to the action of natural and propane gases.

WARNING:

This appliance, when installed, must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with National Electrical Code,

ANSI/NFPA 70 or the Canadian Electrical Code, CSA C22.2,

as applicable.

WARNING:

Gas Ovens: Do not connect oven to electrical supply

until after gas connections have been made.

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 10 REV 7-2022

INSTALLATION (Part 3 of 6) .

See the Dimensions and Utility Connections section of this manual for oven electric connect-point

locations. Power can be connected at the electrical knockout holes in the oven. A flexible conduit or

cord is required. Provide sufficient length to allow the oven to be moved for cleaning without applying

tension to the connections.

Electric Ovens: Ensure that electrical supply matches voltage listed on the ovens data label. All electric

models require a 110/120V, 60Hz, 20A power supply as well as one of the following electrical supplies.

Volts Phase kW

Amps

MCA MOP

L1

L2

L3

208

3

12.5

39

26

39

50

60

240

3

12.5

30

30

30

40

50

480

3

12.5

15

15

15

20

30

Route electrical supply through knockout at rear of oven. Connect supply high voltage to terminal block

located within electrical control compartment at right rear side of oven and low voltage (120VAC) to

the black and white wires as shown.

Gas Ovens: All gas models are provided with a 6 ft power supply cord. The oven requires a dedicated

110/120V, 60Hz, 20A single phase power supply with ground. Note: The Commonwealth of

Massachusetts requires that gas flow must be prohibited when exhaust hood is not operational. If

installing oven in Massachusetts, or where a hood interface is required, remove the jumper wire from

the two-pole terminal block and connect the two wires from the hood sensing switch there.

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 11 REV 7-2022

INSTALLATION (Part 4 of 6) .

Venting

Ventilation requirements vary with each installation and must comply with applicable portions of the

National Fire Protection Association Standard 96 as well as all State and local codes.

Install the exhaust fan interlock. A connection point (5A max) is provided for indirect venting (standard

exhaust hood). Connect point is located in the electrical connection box at right rear side of oven.

Consult local codes for vent interlock requirements.

Indirect venting (standard exhaust hood): Position the oven under the hood with adequate overhangs

and exhaust rates to completely capture the byproducts of combustion discharged from the flue. See

illustration below. From the termination of the flue to the filters of the hood venting system a clearance

of 18” must be maintained. The exhaust hood fan can be directly interlocked to the oven. Refer to the

Wiring Diagrams of this manual for terminal location.

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 12 REV 7-2022

INSTALLATION (Part 5 of 6) .

Water Connections

See Dimensions and Utility Connections section of this manual for water connect point location. Oven

water supply should have a hardness of 4-6 grains per gallon, a pH of 6.5-8.0 and chlorides of less than

30 ppm. Water conditions outside of these parameters may void the warranty. Consult your local water

company and or water condition dealer before connecting water supply to oven.

Connect cold water supply to 1/2” NPT fitting located at rear of the oven. Use a 6 ft or longer flexible

water line.

If your oven is used with a proofer insert, it is recommended that a separate water line is provided.

Drain Connections

See Dimensions and Utility Connections section of this manual for drain connect point location. Connect

a 1/2” drain line to 1/2” NPT drain connector located at rear of oven. Route drain line to floor drain

allowing a minimum 1” air gap between drain line outlet and floor drain.

If your oven is used with a proofer insert, it is recommended that a separate drain line is provided.

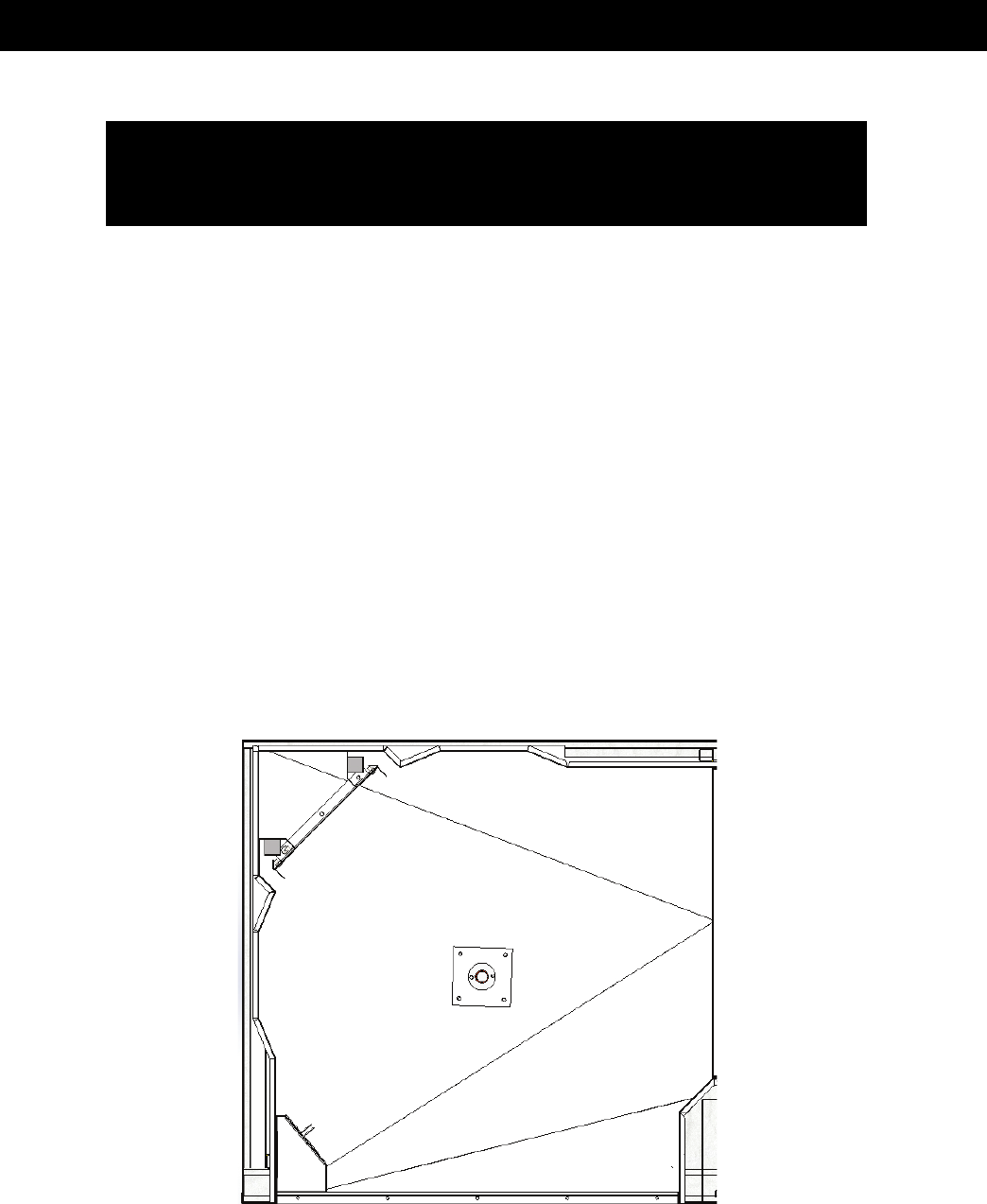

Shutter Settings

Top View of Oven Interior

WARNING:

Plumbing connections must comply with applicable Sanitary, Safety and

Plumbing Codes.

Rear shutter

Middle shutter

Front shutter

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 13 REV 7-2022

INSTALLATION (Part 6 of 6) .

Position

Front Shutter

Middle Shutter

Rear Shutter

inch

mm

Fraction

inch

mm

Fraction

inch

mm

Fraction

1 (top)

0.32

8

5/16

0.25

6

1/4

0.38

10

3/8

2

0.18

5

3/16

0.29

7

9/32

0.38

10

3/8

3

0.15

4

5/32

0.18

5

3/16

0.32

8

5/16

4

0.15

4

5/32

0.21

5

3/16

0.32

8

5/16

5

0.18

5

3/16

0.21

5

3/16

0.29

7

9/32

6 (bottom)

0.25

6

1/4

0.41

10

13/32

0.41

10

13/32

Shutter Settings

Appliance Restraint

Adequate means must be provided to limit the movement of the appliance.

STARTUP PROCEDURE and CHECK LIST (Part 1 of 3) .

LMO START-UP FORM: This form MUST BE SIGNED & RETURNED to LBC via Email to

[email protected]om or FAX 425-642-8310, in order for the Customers Warranty to

take effect.

**REQUIRED TOOLS/METER: manometer, multi-meter, amp clamp, combustion

meter/gas analyzer, 6' ladder, variety of standard & metric hand tools (including

allen wrenches)

LMO Oven Inspection Procedure

Specifics

Serial Number

________________________________________

Model Number

________________________________________

Location Name

________________________________________

Address

________________________________________

City, State

________________________________________

Photos:

(Attach the following Photos to this inspection):

Any visible

damage

_____________

Data plate

_____________

Power Connection in the oven connection box

_____________

Water Supply (filter, RO system or softener)

_____________

Gas Supply

Pipe

_____________

Location Details:

AS FOUND

If No,

CORRECTED?

Oven on Non-combustible floor?

Y_____

N_____

_____

Is the oven

Level?

Y_____

N_____

_____

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 14 REV 7-2022

STARTUP PROCEDURE and CHECK LIST (Part 2 of 3) .

Oven Type:

Gas Nat____ Prop.___

Electric (Voltage) 208 Volts______ 240 Volts______ 480 Volts ________

Install Quality:

Supply voltages: Dedicated 120 VAC, 15Amp Max Rating

Y_____

N_____

_____

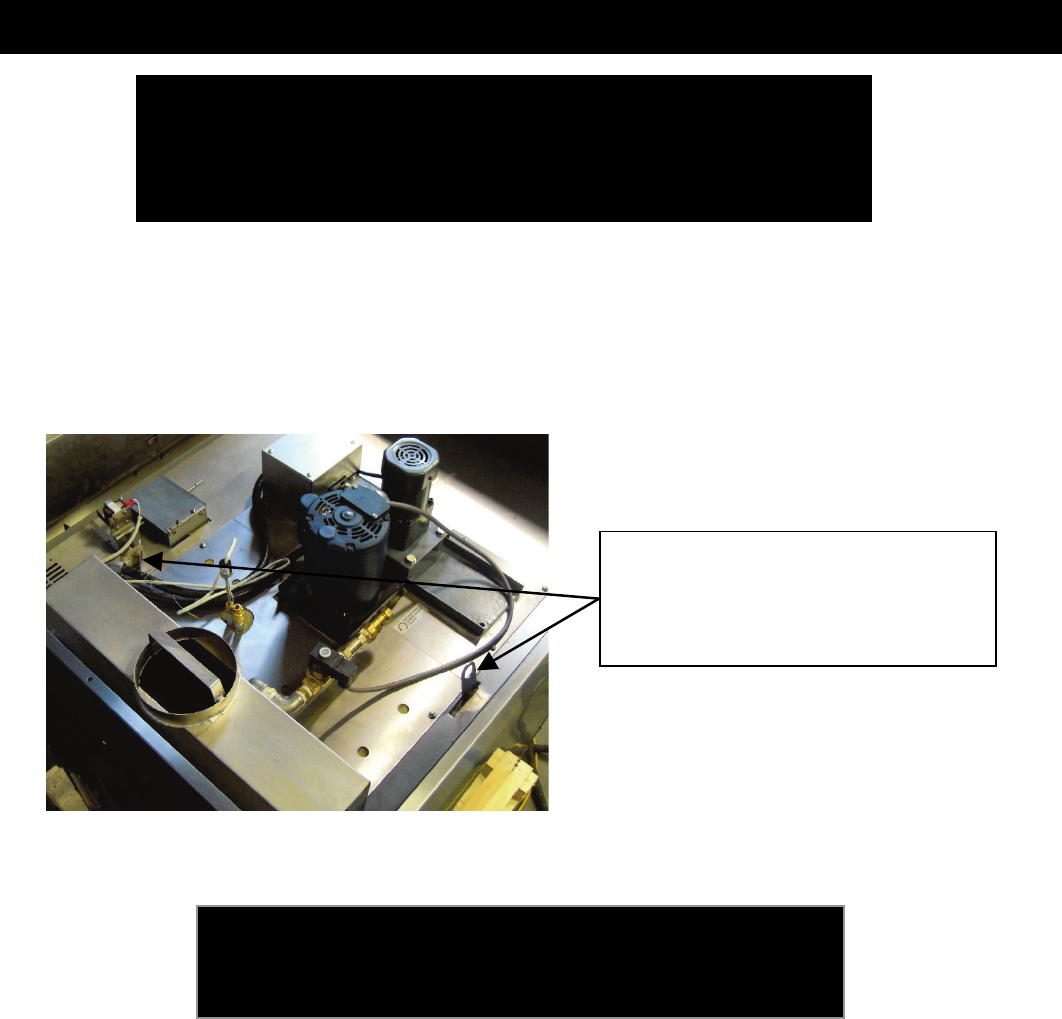

Water Connection: No leaks? (Fig. 1)

Y_____

N_____

_____

Gas Connection: No leaks? (Fig. 2)

Y_____

N_____

_____

Drain Connection: Properly connected and

to an air-gap drain? (Fig. 3)

Y_____

N_____

_____

If hood interlock is required; confirm proper connection and

hood power switch is properly labeled

Y_____

N_____

_____

Functional Check: Turn on power to oven.

Press power button on control. Unit turns on?

Y_____

N_____

_____

Interior lights turn on when the door is opened?

Y_____

N_____

_____

Blower motor rotation: Counter-Clockwise when viewed

from top? (Should be CCW)

Y_____

N_____

_____

Rack starts to rotate smoothly?

Y_____

N_____

_____

Burner test:

Set to 125° F. (Temp starts to rise within a

minute?):

Y_____

N_____

_____

(If temp does not start to rise, Call

LBC)

Supply side gas pressure when burner is running?

_____

WC

_____

(If less than 5" and greater than 14", Call LBC)

Set to 300° F. Minutes to go from 150° to 250° F?

_____

Mins

Combustion Test:

Set to 350° F. Wait one minute:

Check Carbon Monoxide for 1 minute.

CO__________PPM

(If greater than 75 PPM, Call LBC)

Take Photo of CO Measurement.

Check sensor VOLTAGE at test point:

____________VAC

(If Voltage is not between 3-6 VDC, call LBC)

Steam Test - Confirm oven temp is at 350°F. Can you hear

the solenoid open and water spraying? Any visible steam?

Y_____

N_____

_____

Rack Stopping Position (Hot Oven):

Carrier Stops at the door when door is opened?

Y_____

N_____

_____

Check Air-Gap settings on pressure panel.

Refer to settings in manual.

Y_____

N_____

_____

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 15 REV 7-2022

STARTUP PROCEDURE and CHECK LIST (Part 3 of 3) .

Final Inspection:

Loading doors open/close freely past 90° without obstruction?

Y_____

N_____

_____

Doors open 1/2" to 1" before motor and rack Stops?

Y_____

N_____

_____

Gas is

on?

Y_____

N_____

_____

Electrical Is on?

Y_____

N_____

_____

Water is on?

Y_____

N_____

_____

Gaskets: Installed and seated correctly?

Y_____

N_____

_____

No cracks or missing pieces?

Y_____

N_____

_____

All screws and electrical are tight? (If not, tighten down firmly)

Y_____

N_____

_____

All plumbing connections are tight and do not leak.

Y_____

N_____

_____

Fig. 1

Fig. 2

Fig.3

FOR TECHNICAL SUPPORT, CALL LBC: 888-722-5686 x1

Name:

__________________________________________ Company:

_____________________________

Signature:

____________________________________________________

Date

____________________________________________________

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 16 REV 7-2022

USING the CONTROL .

Digital Control (-70)

J

A

B

C

D

E

F

G

H

I

K

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 17 REV 7-2022

Digital Control (-70)

Power On

When power to the oven is on and all circuit breakers are turned on, the green LED in the corner of

the “On/Off” button will be lit. To turn the oven on, press the “On/Off” button (A). The display will

light up and indicate that the control and the oven are on. If the oven door is closed, the oven will

begin to heat to the temperature indicated in the “Set Point” display.

To set the Temperature

Use the up and down buttons (B) next to the “Set Point” display to set the oven to the desired

temperature. This temperature can be adjusted at any time. The oven will heat or cool to this set

point. The actual temperature will fluctuate up and down about the set point as indicated in the

“Actual” temperature display. Note: Allow the oven to operate for one hour at the desired

temperature before you begin to bake.

To set the Bake Timer (Normally set in minutes)

Use the up and down buttons (C) next to the timer display to set the bake time. This timer indicates

the remaining time in the bake and can be adjusted at any time. The display will show the

remaining time in full minutes. An example of this is that if the time is set to 1 minute, it will show 1

minute as it counts down to zero seconds.

The time can also be set to less than one minute or up to 59 seconds. To choose seconds, press the

down button that is to the right of the time display until it reaches zero minutes. Continue to hold

the down button for an additional 5 seconds. The display will change to show a time of 01 with a

decimal point showing. This indicates one second. Press the up button to increase the time up to

59 seconds. Increase the time setting to greater than 59 seconds to return to full minute settings.

To set the Steam Timer

Use the up and down buttons (D) next to the steam timer display to set the steam time. Note that

the steam time is limited by preset parameters in the control. This timer indicates the remaining

time in the steam event. When the steam event is complete, the steam timer display will indicate

“—“.

To set the Blower Functions

The blower button (E) selects the way the circulation blower will operate during the bake. There are

three options: 1) “ON” will cause the blower to operate at all times while the oven is baking except

during the time that the steam timer is counting down. 2) “PULSE” will cause the blower to turn on

and off during the bake cycle to slow the baking process down. 3) “DELAY” will cause the blower to

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 18 REV 7-2022

stay off for the first 90 seconds after the start button is pressed. Note that this function will be

locked out if the control is configured with the programming limitation feature turned on.

To set Vent Functions

The vent button (F) selects the way the vent will operate during the bake. There are three options:

1) “OPEN” will cause the vent to be open all times while the oven is baking except during the time

that the steam timer is counting down. 2) “AUTO” will cause the vent to open during the last third

of the bake cycle. 3) “CLOSED” will cause the vent to stay closed through the entire bake cycle.

Note that this function will be locked out if the control is configured with the programming

limitation feature turned on.

To start the Bake Timer

Press the “START/STOP” button (G) to start the bake after loading the oven with the rack of product. The

loading door must be closed for the bake timer to start. Once the start button is pressed, the steam time will

count down if the steam time is set. If the loading door is opened, the bake timer and steam timer will

pause. The timers will resume automatically when the door is closed.

End of Bake Alarm

When the time has run out, the time display will show two dash lines. The timer alarm will sound. You may

add time to the bake by pressing the up button (C) in the timer display. The timer will automatically resume.

You may also press the “START/STOP” button (G) to silence the alarm and then adjust the time. If you press

the “START/STOP” button (G) again, the displays will reset to the original bake time and steam time. You may

also open the door to silence the alarm and check the baking progress.

Selecting Preset Recipes

To select a preset recipe, press the left and right buttons next to the “SELECT PRESET” display (I). The preset

that is shown will be the recipe that will be operating when the “START/STOP” button (G) is pressed. Note: if

the control is configured for Step Recipe operation, the six buttons above the “SELECT PRESET” will indicate

the step that is being executed (see Step Recipe Operation for specific instructions).

Saving a Preset Recipe

A recipe may be saved as a preset recipe in the following manner. 1) Select the preset number (H) under

which you want to save the recipe. 2) Enter all of the settings. 3) press the “SAVE” button (J) twice. Note

that this function will be locked out if the control is configured with the Programming Limitation (PL) function

turned on. In order to save a recipe, the programming limitations feature must be turned off to save and can

then be turned on to prevent any changing the recipe.

Step Recipe Operation

The control can be configured to operate in Step mode. In step mode, the control creates six sequential

recipe steps and executes all six in order. The step mode is best utilized with preset recipes only.

Recipe Set-up in Step Mode

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 19 REV 7-2022

When the step mode is turned on, the preset recipe is selected using the left and right buttons in the “SELECT

PRESET” display. The step is selected using the six numbered buttons above the “SELECT PRESET” display.

To save a recipe with Step Mode on

Select the recipe number you wish to program. Press step button 1 and enter the recipe parameters. Press

step button 2 and enter the recipe parameters. Repeat this through all the steps. Make sure that you set the

time to “00” in the steps you don’t want. Press the save button twice to save the recipe.

Note: When the oven is configured to operate in Step mode, all recipes must be programmed as steps, even

if you only want one step. Be sure that the remainder of the steps have “00” time.

To Change between Degrees F and Degrees C

The control can change from one temperature scale to the other. To change, simply press the button (K)

marked “F/C”. The oven can also be configured to lock in either degrees F or degrees C.

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 20 REV 7-2022

SCHEMATICS (Part 1 of 4) .

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 21 REV 7-2022

SCHEMATICS (Part 2 of 4) .

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 22 REV 7-2022

SCHEMATICS – ELEC OVENS (Part 3 of 4) .

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 23 REV 7-2022

SCHEMATICS – GAS OVENS (Part 4 of 4) .

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 24 REV 7-2022

ILLUSTRATED PARTS LIST (Part 1 of 8) .

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 25 REV 7-2022

ILLUSTRATED PARTS LIST (Part 2 of 8) .

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 26 REV 7-2022

ILLUSTRATED PARTS LIST (Part 3 of 8) .

n

Item

No

Part No Description Qty

1

151-741

Door Assembly

2

2

151-499

Spacer Bushings

2

3

151-500

Door Mount

1

4

73000-10

Sprocket (35B, 13TG)

2

5

151-503

Bronze Bearing

4

6

151-744

Door Linkage Assembly

2

7

Chain Link

Chain and Master Link (35B)

2

8

151-745

Bottom Door Support

1

9

CR-34

Cam Follower

2

10

151-798

Door Switch Magnet Assembly

1

11

51001-17

Bottom Door Handle Spring

1

12

151-493

Silicone Lap Strip

2

13

151-518

Inner Door Latch

2

14

151-792

Door Handle Assembly

1

15

51001-16

Top Door Handle Spring

1

16

72602-24-5

Vertical Door Gasket

1

17

180-762-2

Reed Switch Assembly (Door sw.)

1

17

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 27 REV 7-2022

ILLUSTRATED PARTS LIST (Part 4 of 8) .

Item

No

Part No Description Qty

1

73000-06a

Driven Gear

1

2

73000-05c

Motor Gear

1

3

30200

-56-1

Motor

Rotation Dr

1

4

70200-11

Bushing

1

5

151-739

Rotator Bottom

Assembly

1

6

150-150-2

Spacer, Rotator

4

7

151-740

Rotator Top

Assembly

1

8

50803-002

Drive Collar

1

9

70200-13

Bushing

1

10

70200-14

Friction Washer

1

11

20601-04

Snap Ring

1

12

151-482

Drive Shaft

1

13

30301-15

Roller Switch

1

14

20104-20

1/4-20 x 3/4” HH

Mach Screw, SS

4

15

20202-05

1/4 Split Lock

Washer, SS

4

16

20104-09

3/8-16 x 5/8” Mach

Cap Screw, SS

8

17

20202-09

3/8 Split Lock

Washer, SS

8

18

20105-20

3/8-16 x 1/2 Mach

Cup Screw, SS

1

19

20105-04

6mm-1mm x

10mm Set

Screw, SS

2

20

151-524

Spacer,

Roller Switch

1

21

151-523A

Rotator Cam

3

22

70200-12

Washer 1.55 ID

1

23

151-524-1

Rack Rotation Plate

1

24

40704-12

Rotation Capacitor

1

25

70200-15

Split Rulon Bushing

(Part not Shown)

1

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 28 REV 7-2022

ILLUSTRATED PARTS LIST – GAS OVENS (Part 5 of 8) .

Item No

Part No

Description

Qty

1

30200-66

Circulation Motor, ½ HP, 115/208-230 VAC

1

2

71500-30

Impeller, Forward Curve

1

3

151-717

Blower Mount Weldment

1

4

151-268

Motor Mount, C-Face

1

5

151-271

Clamp, Blower Seal

1

6

151-270

Seal, Blower

1

8

151-272

Stiffeners, Blower Plate

2

11

151-273b

Blower Involute

1

12

151-211

Pipe, Temperature Sensor

1

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 29 REV 7-2022

ILLUSTRATED PARTS LIST – GAS OVENS (Part 6 of 8) .

Item

No

Part No Description Qty

1

151-722

Exhaust Collector

1

2

151-727

Exhaust

Restrictor

1

3

151-719

Chimney

1

4

151-702b

Heat

Exchanger

1

5

151-160

Burner Box

1

6

151-311

Mount, Burner

- Left

1

7

151-312

Mount, Burner

- Right

1

8

151-313

End, Burner

Assembly

2

9

80400-01

Orifice*

15

10

150-215

Gas Pipe Assy

1

11

151-310

Manifold

1

12

70305-01

Elbow, 1/2NPT

- Steel

1

13

70305-09

Elbow, 3/4NPT

- Steel

1

14

70307-02

Reducer, Pipe

– 3/4 x 1/2 NPT,

Steel

1

15

70302-08

Nipple, Close

– 1/2NPT, Steel

1

16

80505-15

Gas Valve,

Combination

1

17

70302-09

Gas Connector

– 18”

1

18

80002-14

Burner, Inshot

15

19

41100-36-1

Flame Sensor

1

20

80302-12

Ignitor, Hot

Surface

1

21

151-763

Burner / Heat

Exchanger Assy

1

* Orifice Sizes:

Natural Gas @ 3.5 inwc =

3/64” (0.047)[1.19mm]

Propane Gas @ 5.0 inwc =

#65 (0.035)[0.89mm]

21 = Complete

Burner / Heat

Exchanger Assembly

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 30 REV 7-2022

ILLUSTRATED PARTS LIST – ELECTRIC OVENS (Part 7 of 8)

Item No

Part No

Description

Qty

1

11091-02-1

Element Assy (4166W @240V)

4

1

11091-03-1

Element Assy (4166W @480V)

4

2

31200-08

Ground Lug, 2-Hole

1

3

30500-07

Term Block, 3-Pole

1

4

151-164b

Cover, Heat Exchanger

1

5

20202-01

Hex Bolt, 6mm-1x12mm, MS

8

6

30700-17

Contactor, 3-Pole, 40A, 24V Coil

1

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 31 REV 7-2022

ILLUSTRATED PARTS LIST – ELECTRIC OVENS (Part 8 of8)

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 32 REV 7-2022

NOTES .

COPYRIGHT © 2020 – 2022 LBC BAKERY EQUIPMENT, INC. 33 REV 7-2022